A novel acetylenylation catalyst for synthesizing 1,4-butynediol and its preparation method

A technology of butynediol and catalyst, which is applied in the direction of catalyst activation/preparation, preparation of organic compounds, physical/chemical process catalysts, etc., which can solve the problems of easy formation of catalysts and loss of copper ions, etc., and inhibit the formation of surface polymers , low preparation cost, good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 260g of silica sol was uniformly dispersed in 2L of distilled water to obtain an aqueous solution of silica sol; 500g of copper nitrate, 23g of bismuth nitrate and 160g of magnesium nitrate were dissolved in 500mL of 8% nitric acid aqueous solution; under stirring conditions, the salt solution and The aqueous solution of the silicon source material is added dropwise to water for reaction at the same time, and the pH value of the reaction is adjusted to 4-5 by using nitric acid and sodium hydroxide, wherein the molar ratio of Si atoms to Cu atoms, Bi atoms, and Mg atoms is 1:0.98:0.02: 0.6, add mass fraction again and be 30% sodium carbonate aqueous solution, make the pH value of the suspension that obtains be 7.0~8.0, continue to stir for 1 hour, leave standstill for 12 hours, the precipitate that separates out is filtered, washed with distilled water, and then The precipitate was re-pulped and placed in a hydrothermal kettle for hydrothermal treatment at 180°C for 50 ho...

Embodiment 2

[0037] Weigh 1000g of sodium silicate and dissolve it in 10L of water to obtain an aqueous solution of sodium silicate; dissolve 540g of copper chloride, 49g of bismuth nitrate, and 150g of magnesium nitrate in 1L of an aqueous nitric acid solution with a mass fraction of 8%, and mix the salt solution and silicon The aqueous solution of the source material is added dropwise to the water for reaction at the same time, and the pH value of the reaction is controlled at 4 to 5, wherein the molar ratio of Si atoms to Cu atoms, Bi atoms, and Mg atoms is 1:0.90:0.05:0.28, and the mass fraction is 23 % sodium hydroxide aqueous solution to neutralize to a pH value of 7.0 to 8.0, continue stirring for 1 hour, and let stand for 12 hours. After hydrothermal treatment at 180°C for 30 hours, the precipitate was filtered, dried at 150°C, and then calcined in a muffle furnace at 400°C for 10 hours to prepare an acetylation catalyst for the synthesis of 1,4-butynediol.

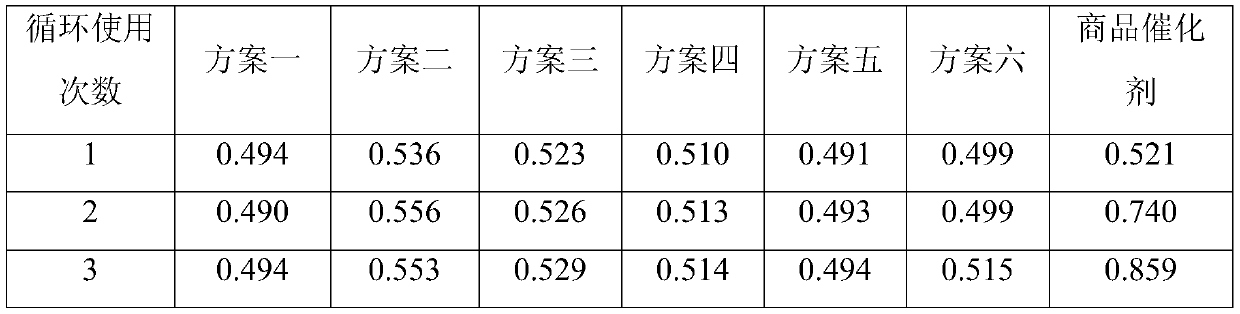

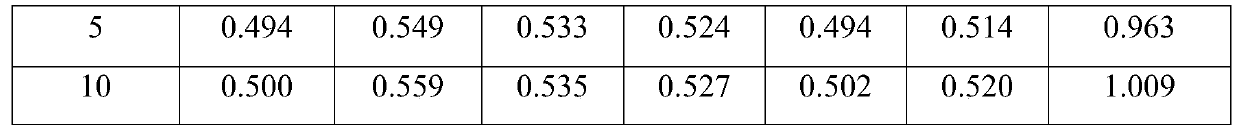

[0038] The obtained al...

Embodiment 3

[0040] Weigh 1220g ethyl orthosilicate and dissolve it in 15L water to obtain an aqueous solution of ethyl orthosilicate; dissolve 180g of magnesium nitrate, 50g of bismuth nitrate, and 900g of copper nitrate in 1L of 8% nitric acid aqueous solution, and dissolve the salt under stirring. The solution and the aqueous solution of the silicon source material are added dropwise to water for reaction at the same time, and the pH value of the reaction is controlled at 4 to 5, wherein the molar ratio of Si atoms to Cu atoms, Bi atoms, and Mg atoms is 1:0.86:0.024:0.10, and then used The mass fraction is 30% sodium carbonate solution and neutralized to pH value of 6.5-7.0, continue to stir for 1 hour, let it stand for 12 hours, the precipitate is filtered, washed with distilled water, and then the precipitate is re-pulped and placed in water Hydrothermal treatment at 150°C for 45 hours in a hot kettle, then filter the precipitate, dry it at 150°C, and bake it in a muffle furnace at 470...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com