Corrosion-resistant microporous mullite lightweight refractory brick and preparation method thereof

A mullite and refractory brick technology, which is applied in the field of corrosion-resistant microporous mullite lightweight refractory bricks and its preparation, can solve the problems of increasing heat energy loss, reducing the heat insulation effect of refractory materials, and increasing energy costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

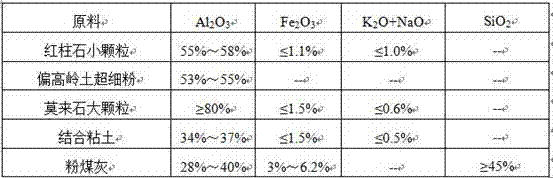

Embodiment 1

[0028] This embodiment provides a corrosion-resistant microporous mullite lightweight refractory brick, which includes a refractory brick base and a high-temperature-resistant coating coated on the surface of the refractory brick base; wherein, the preparation raw materials for the refractory brick base include : Mullite large particles 20%, andalusite small particles 15%, metakaolin superfine powder 24%, bonded clay 10%, expanded graphite 0.5%, fly ash 15%, hollow glass microspheres 4.5%, pulp water 11 %; The raw materials of the high-temperature-resistant coating include: 65% silica airgel, 15% yttrium oxide gel, 1% potassium hexatitanate whisker, 5% nano-silicon nitride, and 14% ethanol.

[0029] Wherein, the particle size of the large mullite particle is 1 mm to 3 mm, the particle size of the small andalusite particle is 0.5 mm to 1 mm, the particle size of the metakaolin superfine powder is less than 0.043 mm, and the hollow glass microsphere The length is less than 1mm. ...

Embodiment 2

[0036] This embodiment provides a corrosion-resistant microporous mullite lightweight refractory brick, including a refractory brick base and a high-temperature-resistant coating coated on the surface of the refractory brick base; wherein, the preparation raw materials for the refractory brick base: Mo 25% large stone particles, 15% small andalusite particles, 15% superfine metakaolin powder, 5% bonded clay, 1.5% expanded graphite, 18.5% fly ash, 5% hollow glass beads, and 15% pulp water; The raw materials for the preparation of the high-temperature-resistant coating include: 70% silica airgel, 15% yttrium oxide gel, 3% potassium hexatitanate whisker, 5% nano-silicon nitride, and 7% ethanol.

[0037] The preparation method of the corrosion-resistant microporous mullite lightweight refractory brick described in this example is the same as that in Example 1. After testing, the density of the corrosion-resistant microporous mullite lightweight refractory bricks prepared in this e...

Embodiment 3

[0039] This embodiment provides a kind of corrosion-resistant microporous mullite lightweight refractory brick, its structure includes a refractory brick substrate and a high temperature resistant coating coated on the surface of the refractory brick substrate; wherein, the refractory brick substrate is obtained The raw materials include: 28.5% large mullite particles, 20% small andalusite particles, 13% metakaolin superfine powder, 7% bonded clay, 1.5% expanded graphite, 15% fly ash, 5% hollow glass beads, Pulp water 10%; the raw materials for making the high-temperature-resistant coating include: silica airgel 65%, yttrium oxide gel 17%, potassium hexatitanate whiskers 3%, nano-silicon nitride 7%, ethanol 8%.

[0040] The preparation method of the corrosion-resistant microporous mullite lightweight refractory brick described in this example is the same as that in Example 1. After testing, the corrosion-resistant microporous mullite lightweight refractory brick prepared in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com