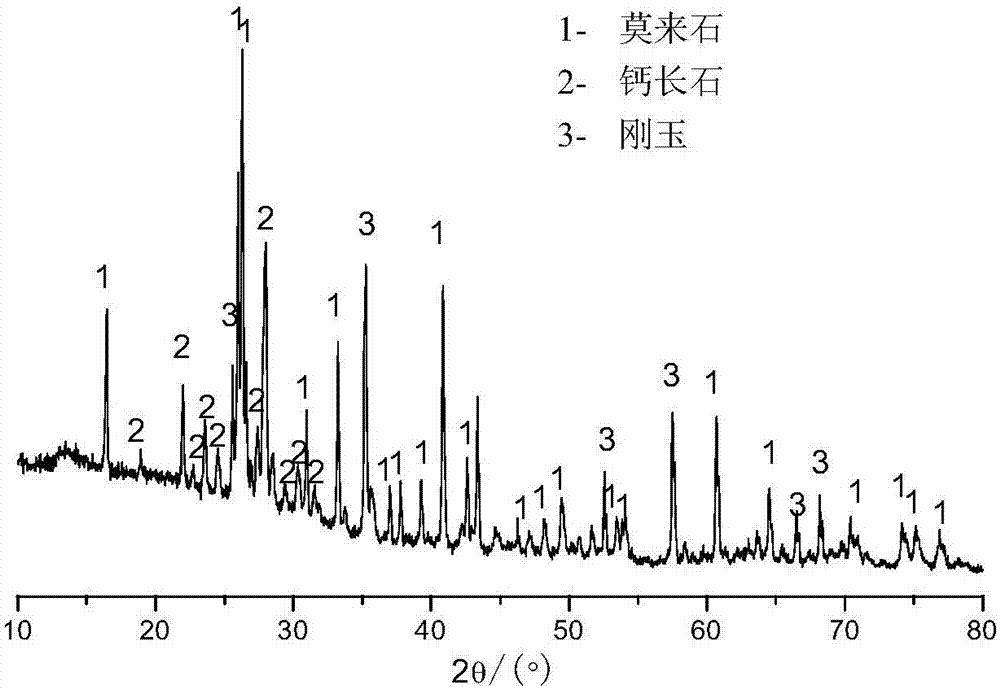

Mullite-anorthite-corundum multiphase microporous thermal insulation material and preparation method thereof

An insulating material and anorthite technology are applied in the field of mullite-anorthite-corundum composite microporous heat insulating material and its preparation, which can solve the problem of uneven pore size of materials, pollution in the production process, and increase production. Cost and other issues, to avoid secondary processing, fast drying time, and environmental protection in the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] According to the mass percentage, mix 40% of the natural raw materials of aluminum and silicon, 20% of the raw materials of alumina, 10% of the expansion agent, 20% of the raw materials of calcium carbonate, and 10% of the inorganic pore forming agent, and then add the above raw materials The weight percent and 6% of the binder are mixed to obtain the mixed mud; the green body is obtained by machine pressing under a pressure of 10MPa, and the green body is dried and put into a high-temperature kiln for 6 hours at 1450°C. After calcining and cooling with the furnace, a mullite-anorthite-corundum composite microporous thermal insulation material is obtained.

[0028] The 40% aluminosilicate natural raw material is composed of 12% kaolinite and 28% bauxite raw ore;

[0029] The 20% alumina material is composed of 5% α-alumina and 15% aluminum hydroxide;

[0030] The 10% expansion agent is composed of 6% kyanite and 4% andalusite;

[0031] The calcium carbonate raw materi...

Embodiment 2

[0037] According to mass percentage, mix 53% of aluminum-silicon natural raw materials, 15% of alumina raw materials, 15% of expansion agent, 10% of calcium carbonate raw materials, and 7% of inorganic pore-forming agents, and then add the above raw materials The weight percentage and 4% of the binder are mixed to obtain the mixed mud; the green body is formed by machine pressing under the condition of 15MPa, and the green body is dried and put into a high-temperature kiln for calcination under the condition of 1410°C for 4 hours. , with furnace cooling, a mullite-anorthite-corundum composite microporous thermal insulation material is obtained.

[0038] The 53% aluminosilicate natural raw material is composed of 23% burnt gems and 30% coal gangue;

[0039] The 15% alumina raw material is composed of 10% aluminum hydroxide and 5% industrial alumina;

[0040] The 15% expansion agent is composed of 8% kyanite, 4% silica and 3% sillimanite;

[0041] The 10% calcium carbonate raw...

Embodiment 3

[0047] According to the mass percentage, mix 70% of the natural aluminum and silicon raw materials, 1% of the alumina raw materials, 16% of the expansion agent, 6% of the calcium carbonate raw materials, and 7% of the inorganic pore-forming agent, and then add the above raw materials The weight percentage and 4% of the binder are mixed to obtain the mixed mud; the green body is machine-pressed under the condition of 13MPa, and the green body is dried and put into a high-temperature kiln for calcination at 1460°C for 5 hours. , with furnace cooling, a mullite-anorthite-corundum composite microporous thermal insulation material is obtained.

[0048] The 70% aluminosilicate natural raw material is composed of 30% bauxite raw ore and 40% coal gangue;

[0049] The alumina raw material is industrial alumina;

[0050] The 16% expansion agent is composed of 6% kyanite, 6% sillimanite and 4% andalusite;

[0051] The calcium carbonate raw material is limestone;

[0052] The inorganic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com