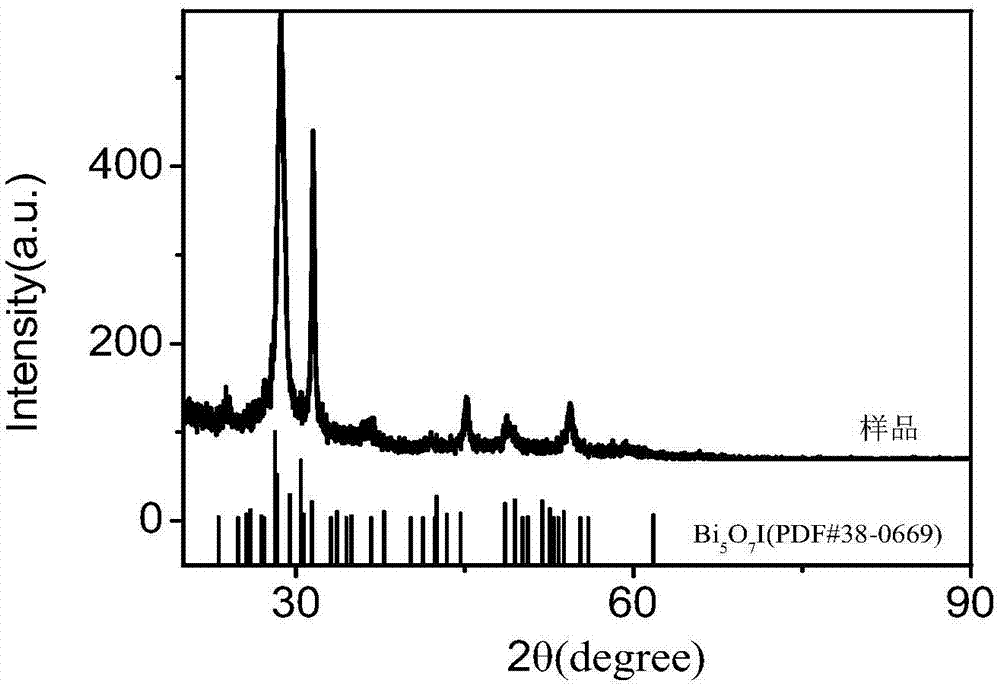

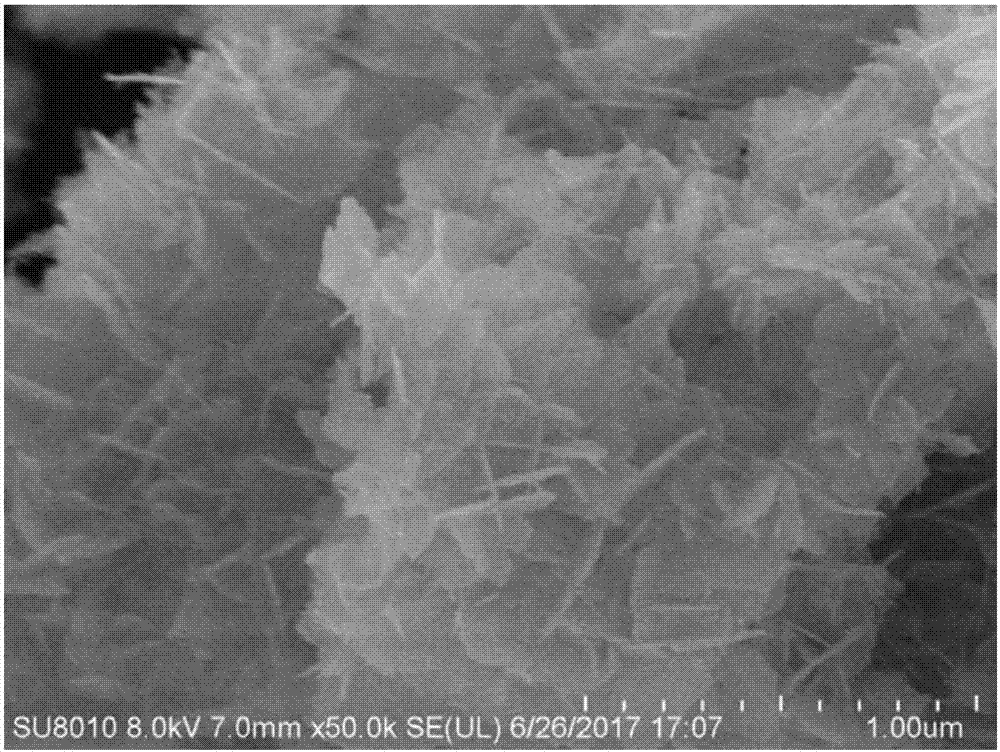

Bi5O7I nano sheet-shaped material, as well as preparation method and application thereof

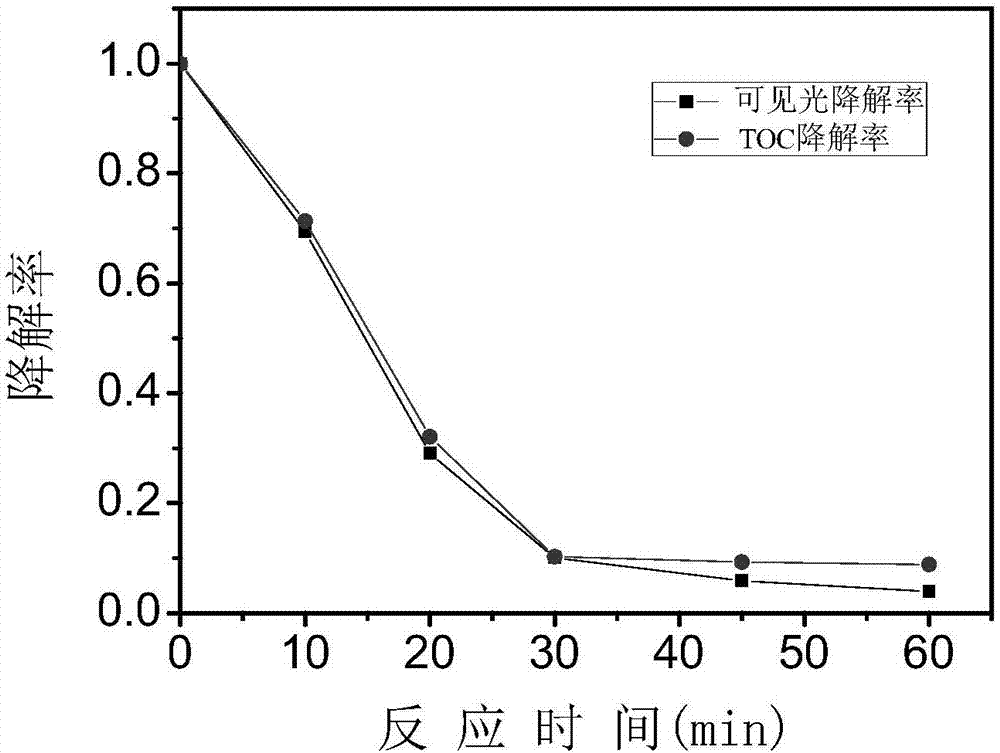

A nano-sheet, hydrothermal reaction technology, applied in chemical instruments and methods, catalyst activation/preparation, inorganic chemistry, etc., can solve the problems that restrict the industrial application of semiconductor photocatalysis technology, the narrow wavelength of semiconductor light absorption, and the recombination of photogenerated carriers. The problem of high rate of degradation, to achieve the effect of good ability to degrade phenolic pollutants, simple preparation process and strong controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] A kind of Bi provided by the embodiment of the present invention 5 o 7 The preparation method of 1 nano sheet material, comprising:

[0019] Dissolve the bismuth-containing compound in ethylene glycol, then add iodized salt, stir well to dissolve. In the present invention, a bismuth-containing compound and an iodine salt are used as raw materials, and ethylene glycol is used as a reaction solvent. The bismuth-containing compound is not easy to be hydrolyzed in ethylene glycol, which is helpful for the reaction to proceed. In particular, the solvent of the present invention cannot contain water, which will affect the progress of the reaction and the formation of the product.

[0020] In order to make the reaction complete, the regular Bi 5 o 7 I material, in a preferred embodiment of the present invention, the molar ratio of the bismuth element in the bismuth-containing compound to the iodine element in the iodine salt is 1:1-2. Preferably, the mass ratio of the bi...

Embodiment 1

[0030] This embodiment provides a Bi 5 o 7 1 nano sheet material, mainly prepares by following method:

[0031] Dissolve 1.56g of bismuth nitrate pentahydrate in 66mL of ethylene glycol, then add 0.996g of potassium iodide, and fully stir to dissolve. The pH of the solution was adjusted to 10 with sodium hydroxide.

[0032] The mixed solution was transferred to a hydrothermal reaction kettle, and hydrothermally reacted at 150° C. for 6 h.

[0033] After the product was cooled to room temperature, the product was centrifuged and precipitated, and the precipitate was washed three times with deionized water and ethanol to obtain a yellow solid powder.

[0034] The solid powder was placed in an oven and dried at 60° C. for 12 hours. Fully grind the solid powder to get Bi5 o 7 1 nanosheet material.

Embodiment 2

[0036] This embodiment provides a Bi 5 o 7 1 nano sheet material, mainly prepares by following method:

[0037] Dissolve 0.73g of bismuth nitrate pentahydrate in 33mL of ethylene glycol, then add 0.498g of potassium iodide, and fully stir to dissolve. The pH of the solution was adjusted to 10 with sodium hydroxide.

[0038] The mixed solution was transferred to a hydrothermal reaction kettle, and hydrothermally reacted at 150° C. for 6 h.

[0039] After the product was cooled to room temperature, the product was centrifuged and precipitated, and the precipitate was washed three times with deionized water and ethanol to obtain a yellow solid powder.

[0040] The solid powder was placed in an oven and dried at 60° C. for 12 hours. Fully grind the solid powder to get Bi 5 o 7 1 nanosheet material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com