Sn2Nb2O7 Photo-anode material and Sn2Nb2O7 photoelectrode film

A photoanode and photoelectrode technology, applied in the field of photoelectrochemistry, can solve the problems of photoelectrochemical performance of photoanode materials, and achieve the effects of alleviating environmental energy shortage, good optical characteristics, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Example 1 Sn 2 Nb 2 o 7 photoanode material

[0024] (1) Preparation method

[0025] By SnO and Nb 2 o 5 The solid-to-liquid ratio of the mixture to ethanol is 1g: 2ml, take 7.5mmol of SnO and 5mmol of Nb 2 o 5 Mix in ethanol, as for the ball mill tank, the grinding balls in the tank are 265g; start the ball mill, set the speed at 200 r / min, grind for 14h, turn off the power, wash with ethanol and dry, and dry the powder in the Annealing treatment at 900°C for 4 hours in a muffle furnace, cooling to room temperature, and obtaining Sn 2 Nb 2 o 7 powder.

[0026] (2) Detection

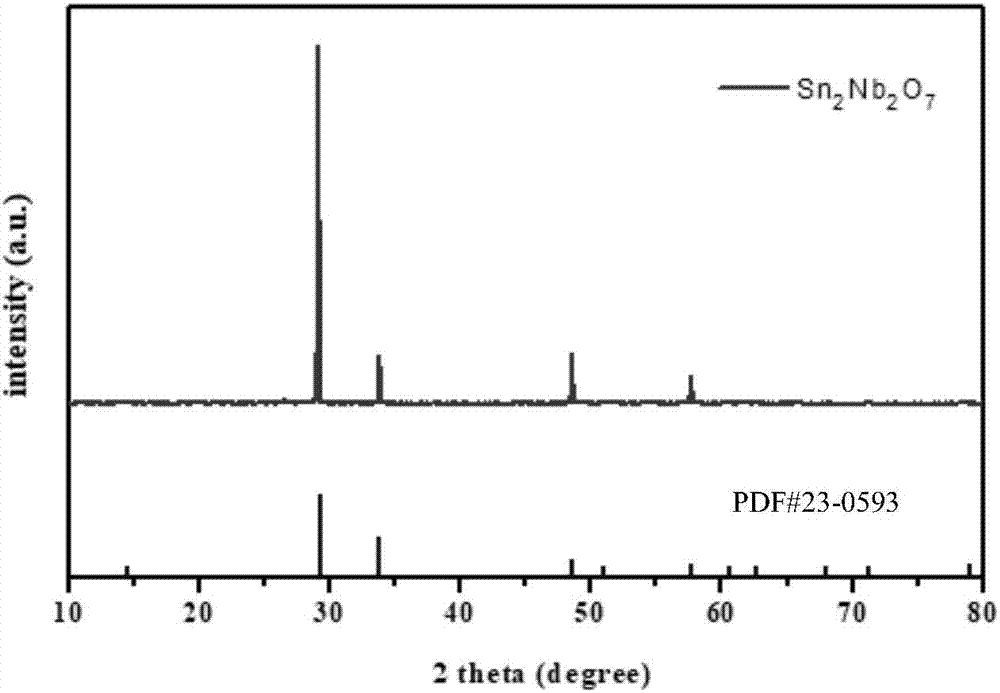

[0027] will get Sn 2 Nb 2 o 7 Powder carries out XRD test, the result is as follows figure 1 shown by figure 1 Visible, Sn 2 Nb 2 o 7 Has good crystallinity.

Embodiment 2

[0028] Example 2 Sn 2 Nb 2 o 7 Photoelectrode film

[0029] (1) Sn 2 Nb 2 o 7 Photoelectrode thin film Sn 2 Nb 2 o 7 -400 preparation

[0030] 1) Take 10mg I 2 Place in 25ml of acetone aqueous solution (the volume ratio of water to acetone is 1:25), seal and sonicate for 60min until the solution is uniformly dispersed, and the mixture containing I 2 of acetone solution.

[0031] 2) get the Sn prepared by 0.1g embodiment 1 2 Nb 2 o 7 Powder dispersed in containing I 2 In the acetone aqueous solution, sealed and sonicated for 90min, the electrophoretic deposition suspension was obtained.

[0032] 3) Two transparent conductive glasses (FTO) with equal areas are immersed in the electrophoretic deposition suspension parallel to each other face to face, and a DC voltage of 20V is applied between the two electrodes, and deposited for 1 min.

[0033] 4) Cut off the current, take the transparent conductive glass (FTO) out of the suspension, dry it at room temperature, and...

Embodiment 3

[0040] Example 3 Sn 2 Nb 2 o 7 Application of Photoelectrode Thin Film

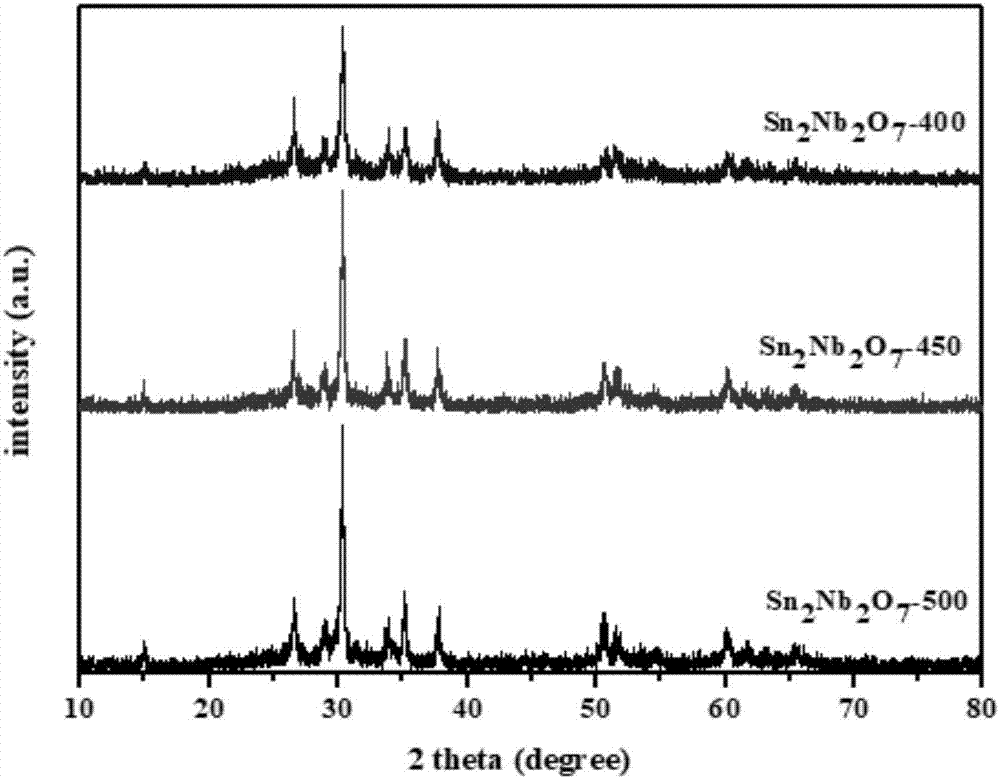

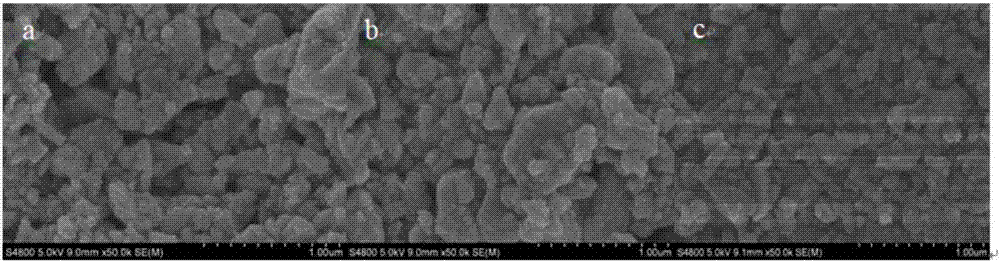

[0041] The Sn prepared by embodiment 2 was respectively 2 Nb 2 o 7 -400, Sn 2 Nb 2 o 7 -450 and Sn 2 Nb 2 o 7 -500 photoelectrode thin films are used for photoelectrochemical performance tests such as photocurrent, impedance, and quantum efficiency.

[0042] All electrochemical experiments were carried out in an electrochemical workstation (Princeton Applied Research 2273) with a three-electrode system. The sample film is used as the working electrode, the platinum sheet is used as the counter electrode, Ag / AgCl is used as the reference electrode, the electrolyte is 0.5M sodium sulfate, and the light irradiation area of the sample is 1cm 2 .

[0043] Photocurrent test: the light source is 300W xenon lamp, the bias voltage is 1.18V vs.V RHE , the measured results are as Figure 4 As shown, the results show that the firing temperature has an effect on the photocurrent, and the photocurrent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com