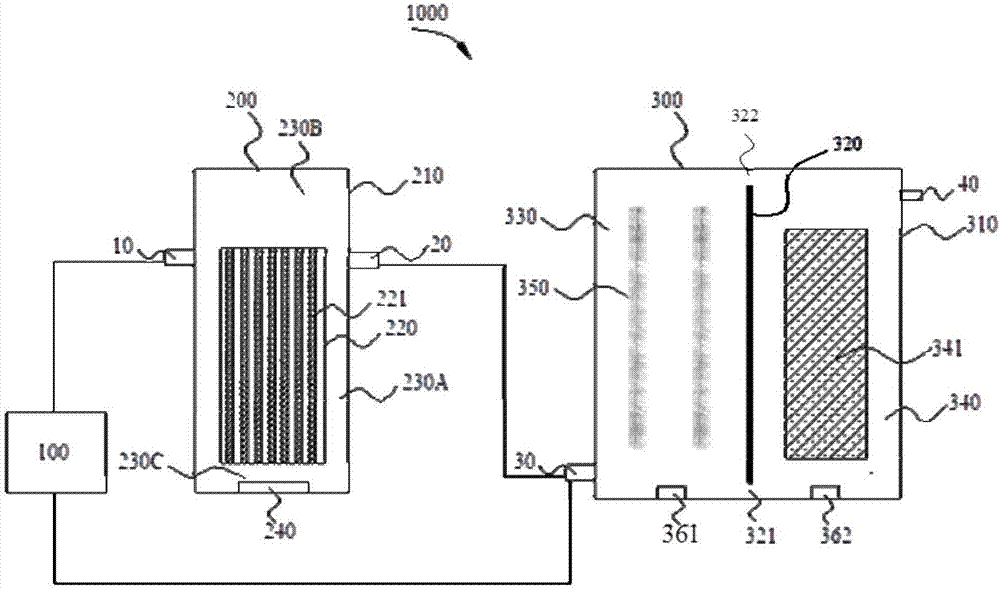

Deep waste water treatment system and sewage treatment method

A sewage treatment system and sewage technology, applied in water/sewage treatment, oxidized water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as the need for improvement in sewage treatment methods, reduce membrane pollution, reduce Free microorganisms, enhance the effect of mass transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0105] Pretreatment - Ozone Advanced Oxidation Treatment - Membrane Biological (MBR) Combined Treatment

[0106] In this embodiment, various pretreatment methods can be used, such as multi-media filtration, sedimentation, etc. Specifically, coagulation sedimentation and security filtration are taken as examples.

[0107] In this embodiment, a variety of advanced ozone oxidation processes can be used, and the series-parallel connection between each process is not unique. Specifically, the series connection of an ozone packed bed and an ozone fluidized bed is taken as an example.

[0108] 1. Coagulation and sedimentation

[0109] (a) Turn on the agitator in the dosing area with a rotation speed of 300 rpm; turn on the agitator in the reaction area with a rotation speed of 50 rpm.

[0110] (b) Turn on the feed water pump and turn on the dosing pump at the same time.

[0111] 2. Security filtering

[0112] (a) Turn on the feed water pump, and close the drain valve after the wat...

Embodiment 2

[0136] Ozone Packed Bed-MBR-Ozone Fluidized Bed

[0137] This embodiment is suitable if the COD of the MBR effluent is still high, that is: the post-fluidized bed process is adopted:

[0138] There are many options for pre-processing in this embodiment, specifically, take multimedia filtration as an example

[0139] 1. Multi-media filtration

[0140] Quartz sand filter is used for pretreatment, and the medium can be quartz sand, anthracite, granular porous ceramics, manganese sand, etc.

[0141] (a) Open the water inlet valve and outlet valve of the filter, turn on the water inlet pump, and adjust the flow rate within the specified range;

[0142] (b) Two sets of filters are used in turn, one for normal filtration and one for backwashing;

[0143] (c) During the backwash process, first close the water inlet valve and outlet valve, then open the backwash water inlet valve, backwash drain valve and air intake valve, and the cleaning time is about 10-30 minutes.

[0144] 2. O...

Embodiment 3

[0152] Ozone Packed Bed - Ozone Fluidized Bed

[0153] This embodiment is applicable to the situation where the COD concentration of the wastewater is low but the biodegradability is extremely poor.

[0154] Step 1 and step 2 are the same as in Example 1, and coagulation sedimentation and security filtration are performed sequentially.

[0155] 3. Ozone Advanced Oxidation

[0156] 3.1 Packed bed

[0157] This step is the same as in Example 1, and can be processed by a single packed bed or by two parallel packed beds.

[0158] 4. Ozone fluidized bed

[0159] This step processing parameter is with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com