High-hardness nano-PU(nano-polyurethane) coating for woodware surfaces and preparation method of coating

A surface coating, polyurethane technology, applied in the field of nanomaterials, can solve the problems of poor flame retardant effect, uneven gloss, reduced resin strength, wear resistance, etc., and achieves improved corrosion resistance, simple preparation process, and strong binding force. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

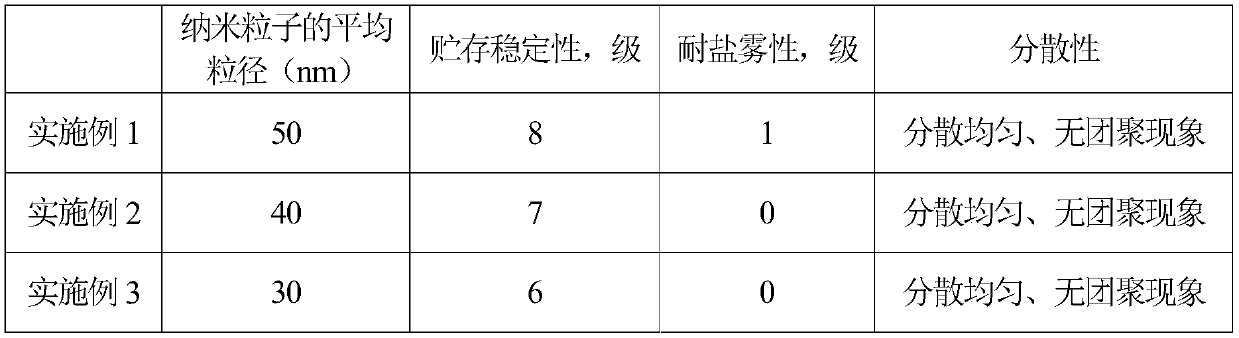

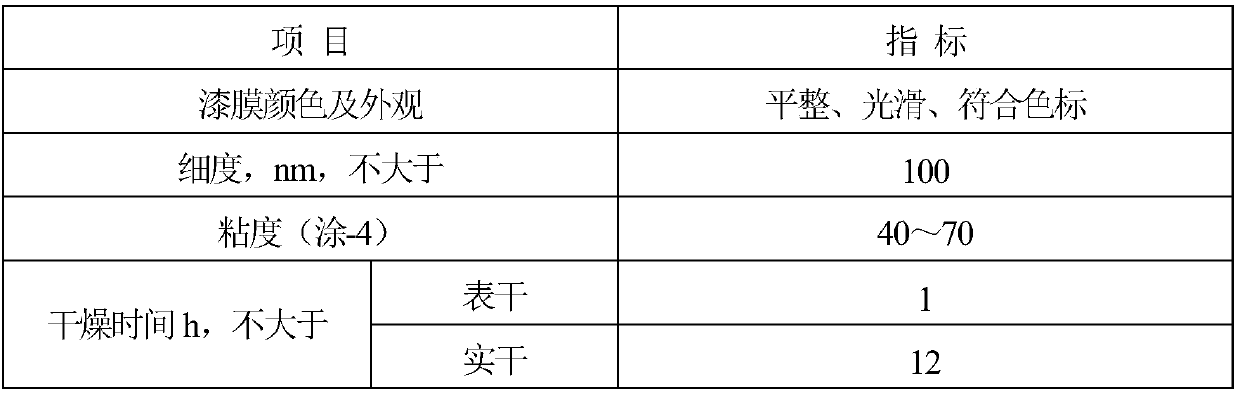

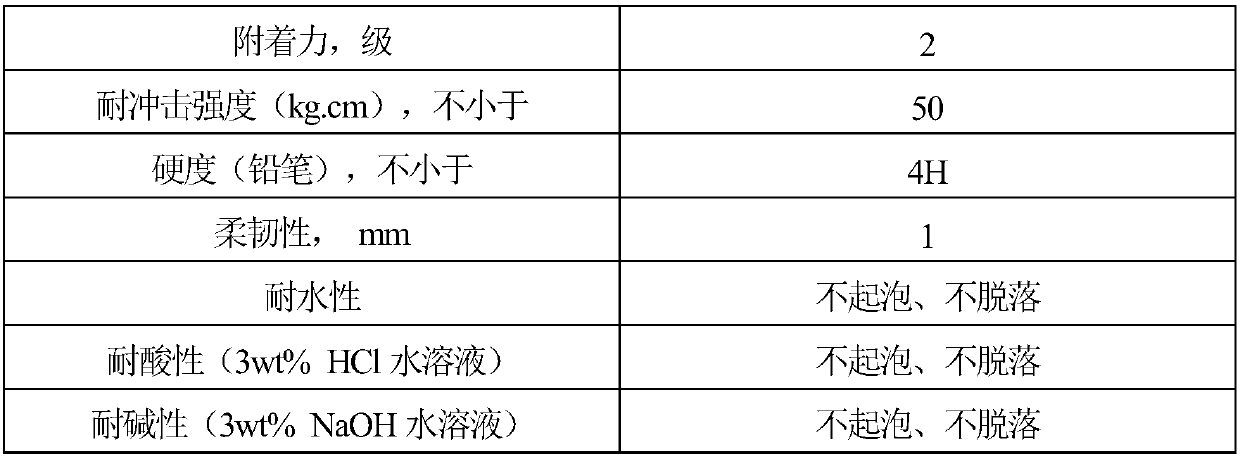

Examples

Embodiment 1

[0033]In this embodiment, the high-hardness nano-polyurethane wood surface coating has the following components and contents in parts by weight: 85 parts of polyurethane resin, 15 parts of unsaturated polyester resin, 18 parts of nano-composite mother liquor, composite corrosion inhibitor 7 parts of organic corrosion inhibitor, 0.8 parts of organic corrosion inhibitor, 2 parts of initiator (methyl ethyl ketone peroxide), 2 parts of flame retardant filler, 7 parts of toluene diisocyanate (TDI) (curing agent), 8 parts of organic solvent; among them, organic corrosion inhibitor The agent is zinc p-nitrocinnamate, the organic solvent is acetone; the flame retardant filler is mixed with quartz powder and antimony trioxide in a weight ratio of 1:1, and the particle size is 50-100nm.

[0034] In the nano-composite mother liquor, the weight ratio of nano-titanium dioxide, nano-silica, nano-zinc oxide and organic solvent is 45:35:25:35, the coupling agent accounts for 4% of the total we...

Embodiment 2

[0043] In the present embodiment, the composition and content of the high-hardness nano polyurethane wood surface coating are as follows in parts by weight: 80 parts of polyurethane resin, 20 parts of unsaturated polyester resin, 15 parts of nanocomposite mother liquor, composite corrosion inhibitor 6 parts of corrosion inhibitor, 1.0 part of organic corrosion inhibitor, 1 part of initiator (methyl isobutyl ketone peroxide), 3 parts of flame retardant filler, 6 parts of diphenylmethane diisocyanate (MDI), 5 parts of organic solvent; The corrosion inhibitor is calcium p-nitrocinnamate, the organic solvent is acetone; the flame retardant filler is mixed with quartz powder and asbestos fiber in a weight ratio of 2:1, and the particle size is 50-100nm.

[0044] In the nano-composite mother liquor, the weight ratio of nano-titanium dioxide, nano-silica, nano-zinc oxide and organic solvent is 40:40:20:50, the coupling agent accounts for 3% of the total weight of the above-mentioned n...

Embodiment 3

[0053] In the present embodiment, the composition and content of the high-hardness nano-polyurethane wood surface coating are as follows in parts by weight: 90 parts of polyurethane resin, 10 parts of unsaturated polyester resin, 20 parts of nano-composite mother liquor, composite corrosion inhibitor 8 parts of corrosion inhibitor, 0.5 parts of organic corrosion inhibitor, 3 parts of initiator (tert-butyl hydroperoxide), 1 part of flame retardant filler, 8 parts of 1,6-hexamethylene diisocyanate (HDI), 10 parts of organic solvent; among them, The organic corrosion inhibitor is zinc p-nitrocinnamate, the organic solvent is acetone; the flame retardant filler is mixed with asbestos fiber and antimony trioxide in a weight ratio of 1:2, and the particle size is 50-100nm.

[0054] In the nano-composite mother liquor, the weight ratio of nano-titanium dioxide, nano-silica, nano-zinc oxide and organic solvent is 50:30:30:20, the coupling agent accounts for 5% of the total weight of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com