A kind of preparation method of polyvinyl chloride

A polyvinyl chloride and polyvinyl alcohol technology, applied in the field of polyvinyl chloride preparation, can solve the problems of large residual organic impurities and inability to directly recycle, so as to reduce the content of organic residues, prevent high fish eyes, and reduce environmental pollution. Optimized effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The preparation method of vinyl chloride comprises:

[0032] The calcium carbide and water are reacted in the generator to generate crude acetylene gas, which is oxidized by concentrated sulfuric acid or sodium hypochlorite to remove impurities such as phosphine and hydrogen sulfide in the crude acetylene gas, and refined to obtain refined acetylene gas with a purity of more than 99%. ; Refined acetylene gas and hydrogen chloride react in the converter with catalyzed mercuric chloride as a catalyst to generate vinyl chloride. The vinyl chloride gas is washed with water and alkali to remove the impurity gas, and then pressurized and compressed to make the vinyl chloride gas phase into Liquid phase, the liquid phase vinyl chloride monomer undergoes rectification to further remove impurities such as low boiler hydrogen, nitrogen, acetylene gas and high boiler dichloroethane, and finally obtain vinyl chloride monomer with a purity of 99.99%.

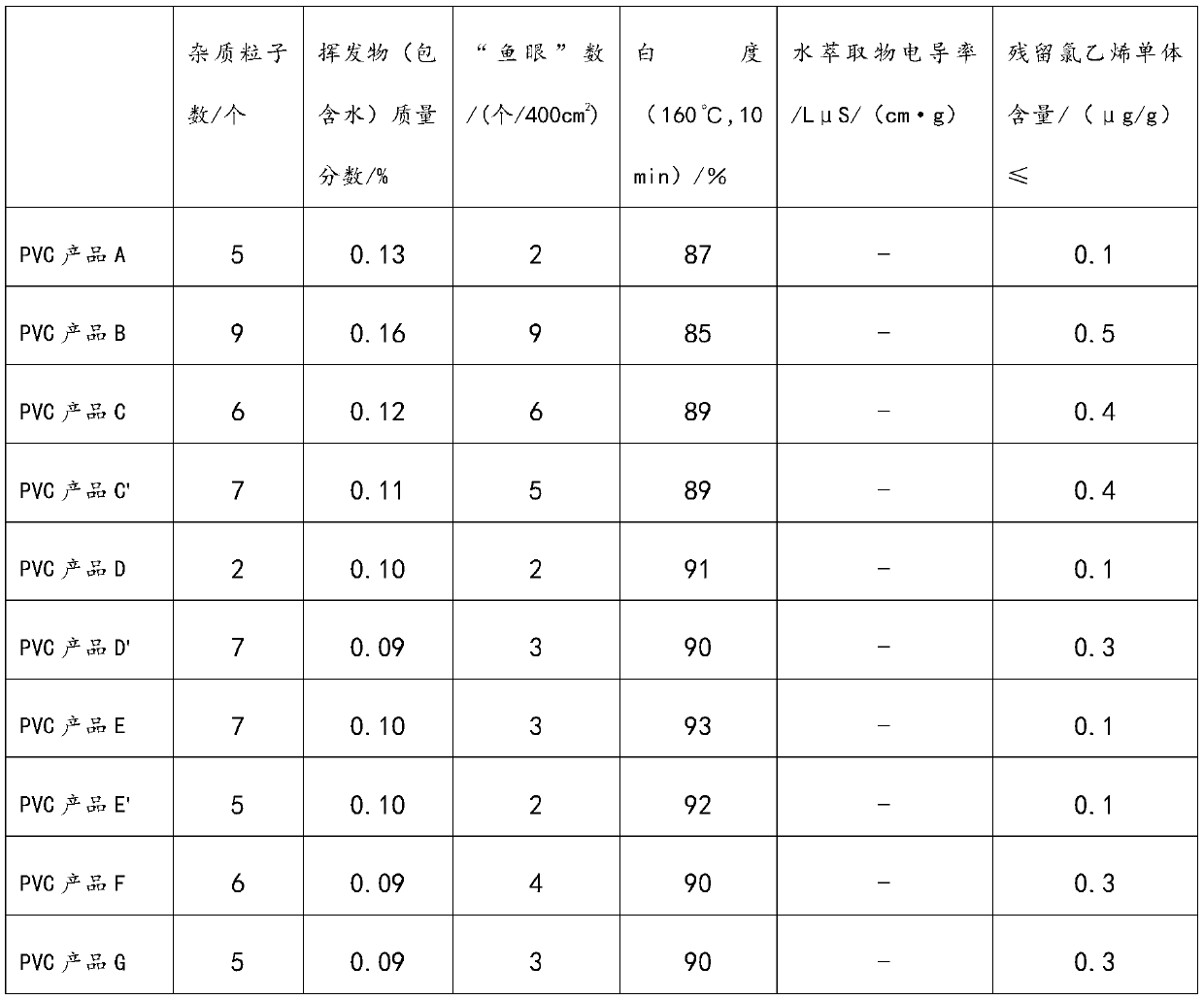

Embodiment 1

[0034] The present embodiment provides a kind of preparation method of polyvinyl chloride, comprising:

[0035] 100Kg vinyl chloride monomer, 0.07Kg dispersant, 0.07Kg peroxydicarbonate bis(2-ethylhexyl) ester (EHP), 0.05Kg ammonium bicarbonate and 120Kg deionized water are introduced into the polymerization reactor, during the reaction Polymerization at a temperature of 56°C and a pressure of 0.85 MPa;

[0036] The dispersant is formed by compounding polyvinyl alcohol with a degree of alcoholysis of 72%, polyvinyl alcohol with a degree of alcoholysis of 78% and polyvinyl alcohol with a degree of alcoholysis of 40% in a ratio of 12:5:1.

[0037] When the pressure drop in the polymerization reactor reaches 0.15MPa (the pressure in the polymerization reactor is 0.70MPa), add 0.07Kg of terminator formed by mixing acetone thiosemicarbazone and bisphenol A according to the mass ratio of 3:1 , solid-liquid separation to obtain PVC product A and mother liquor A.

Embodiment 2

[0039] The present embodiment provides a kind of preparation method of polyvinyl chloride, comprising:

[0040] 100Kg vinyl chloride monomer, 0.07Kg polyvinyl alcohol (alcoholysis degree is 88%), 0.05Kg hydroxypropyl methylcellulose, 0.07Kg cumyl peroxide neodecanoate (CNP), 0.07Kg peroxide Bis(2-ethylhexyl) dicarbonate (EHP), 0.06Kg ammonia water and 150Kg deionized water were introduced into the polymerization reactor, and the reaction temperature was 38°C and the pressure was 0.48MPa. Polymerization reaction;

[0041] When the pressure drop in the polymerization reactor reached 0.05MPa (the pressure in the polymerization reactor was 0.43MPa), add 0.14Kg terminator diethylhydroxylamine, and separate the solid and liquid to obtain PVC product B and mother liquor B.

PUM

| Property | Measurement | Unit |

|---|---|---|

| alcoholysis degree | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com