Complex phase powder and preparation method thereof

A technology of powder and precursor powder, which is applied in the field of multi-phase powder and its preparation, can solve the problem of difficult control of powder morphology and phase composition, uneven distribution of powder components and phases, and complex process methods of multi-phase powder and other problems, to achieve the effect of no environmental pollution, uniform particle size, and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

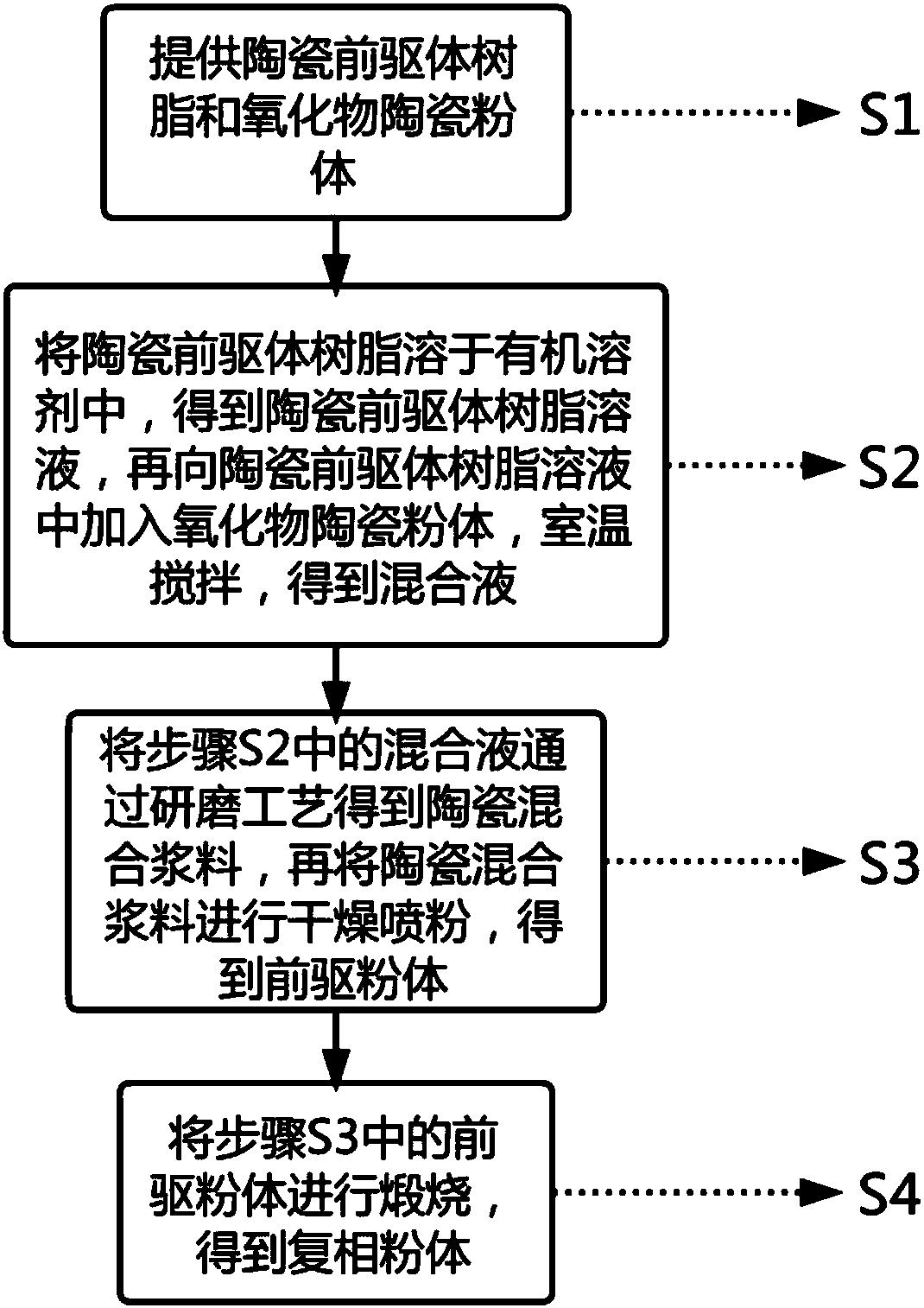

[0030] See figure 1 , the preparation method of the composite powder shown in the present invention comprises the following steps:

[0031] S1. Provide ceramic precursor resin and oxide ceramic powder. The ceramic precursor resin includes alumina ceramic precursor resin, zirconia ceramic precursor resin, silicon oxide ceramic precursor resin or titanium oxide ceramic precursor resin. Any one; the oxide ceramic powder includes any one of alumina ceramic powder, zirconia ceramic powder, silicon oxide ceramic powder or titania ceramic powder;

[0032] S2. Dissolving the ceramic precursor resin in an organic solvent, the organic solvent includes any one of ethylene glycol ether, absolute ethanol, n-propanol or toluene, configured so that the mass ratio is preferably 0.1 to 75 wt%. ceramic precursor resin solution, and then add the oxide ceramic powder to the ceramic precursor resin solution, and stir at room temperature to obtain a mixed solution;

[0033] S3. Add the mixed solu...

Embodiment 1

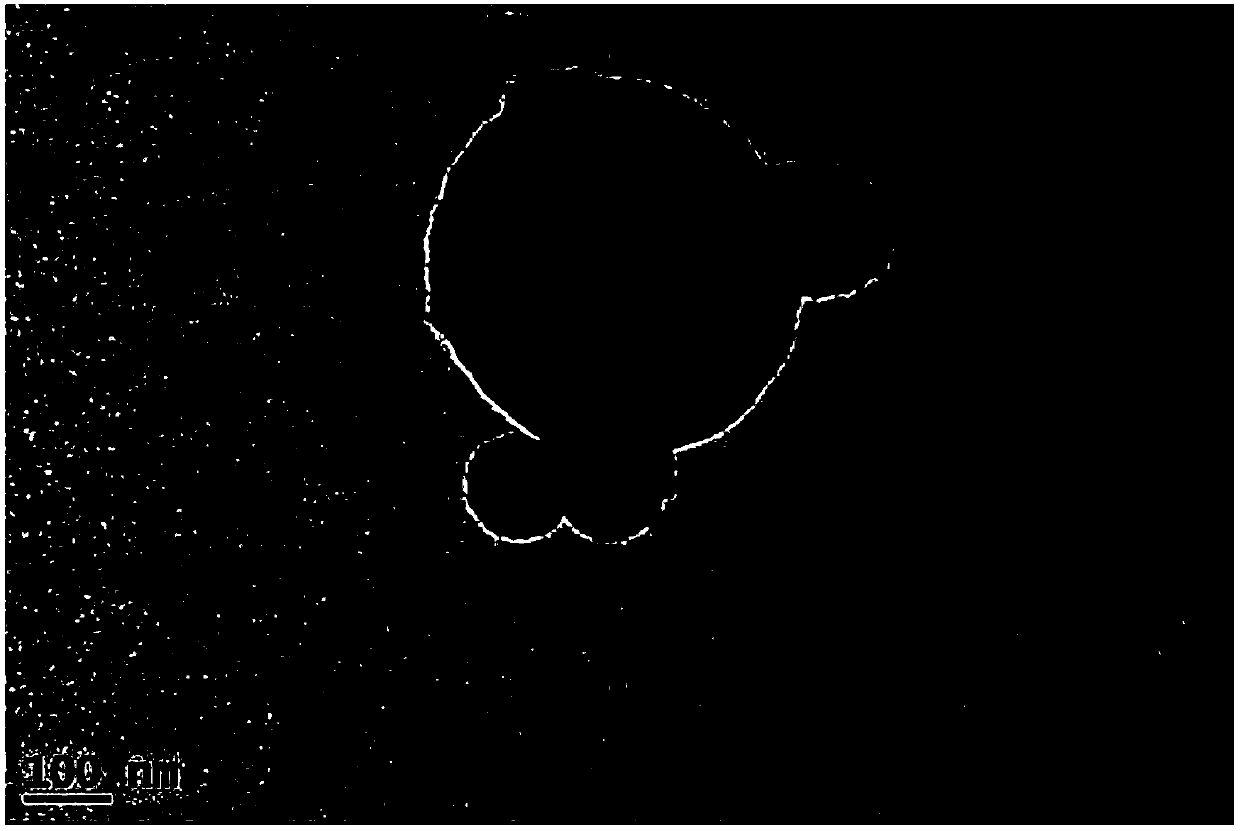

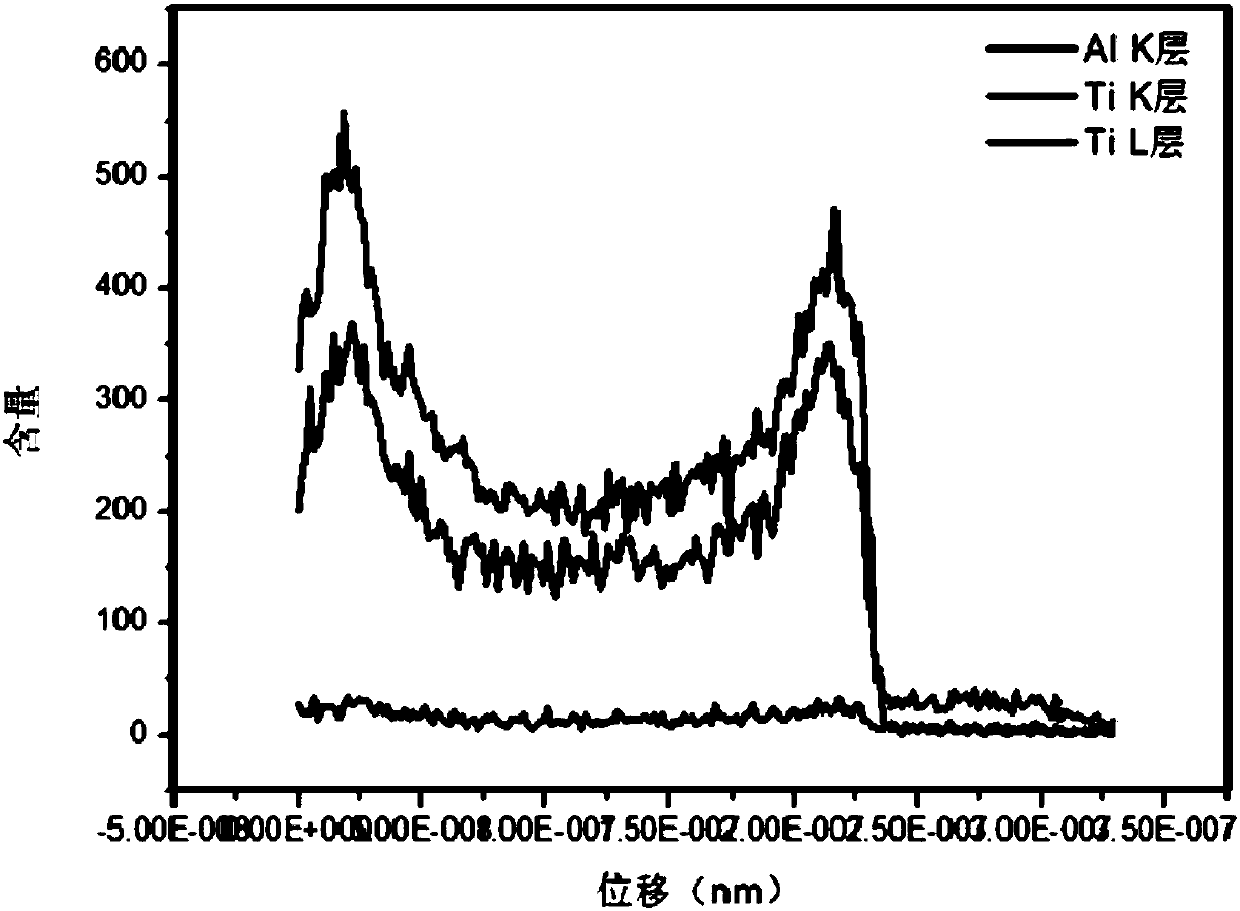

[0037] Weigh 39.58g of titanium oxide ceramic precursor resin and dissolve it in n-propanol to form a titanium oxide ceramic precursor resin solution with a mass ratio of 15wt%. Then weigh 39.58g of alumina ceramic powder and slowly add it to the Add and stir the titanium ceramic precursor resin solution at room temperature to obtain a mixed solution. The mixed solution is evenly mixed and ground by a pin-type sand mill, and the ceramic mixed slurry is obtained after the grinding is completed, and then the ceramic mixed slurry is put into a spray drying device for drying and powder spraying to obtain a precursor powder. Finally, the obtained precursor powder is calcined at a temperature of 350°C for 2 hours to obtain a titanium oxide-alumina multi-phase submicron powder with a core-shell structure and doped with multiple elements. Please refer to Figure 2 to Figure 4 , it can be seen from the figure that the titanium oxide ceramic precursor resin is evenly coated on the surfa...

Embodiment 2

[0039] Weigh 38.03g of alumina ceramic precursor resin and dissolve it in absolute ethanol to configure a mass ratio of 7wt% alumina ceramic precursor resin solution, then weigh 150.53g of zirconia ceramic powder, slowly add to the oxidation The aluminum ceramic precursor resin solution is added and stirred at room temperature to obtain a mixed solution. The mixed solution is evenly mixed and ground by a pin-type sand mill, and the ceramic mixed slurry is obtained after the grinding is completed, and then the ceramic mixed slurry is put into a spray drying device for drying and powder spraying to obtain a precursor powder. Finally, the obtained precursor powder is calcined at a temperature of 1000°C for 10 hours to obtain a multi-element-doped alumina-zirconia multi-phase submicron powder. Please refer to Figure 5 to Figure 8 , it can be seen from the figure that the alumina ceramic precursor resin is evenly coated on the surface of the zirconia ceramic powder, forming a sphe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com