Method for preparing ACE (angiotensin converting enzyme) inhibitory peptide by using shellfish meat

A technology for inhibiting peptides and shellfish meat, applied in the field of preparing ACE-inhibiting peptides from shellfish meat, can solve the problems of high yield of ACE-inhibiting peptides, immature technology, and large amount of enzymes, so as to reduce the difficulty of operation, improve the fermentation efficiency, and improve the efficiency of the fermentation process. separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

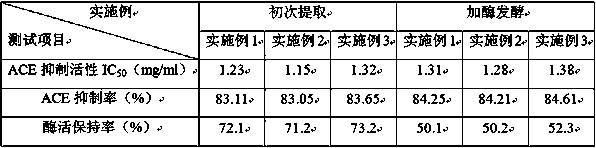

Examples

Embodiment 1

[0042] A. Fresh shellfish is steamed, chopped, and placed in a -20°C refrigerator for freezing. After 6 hours, it is transferred to a vacuum freeze dryer, freeze-dried for 48 hours, and crushed through a 40-mesh sieve to obtain dried shellfish powder;

[0043] B. adding the dried shellfish powder to distilled water for homogenization according to the material-to-liquid ratio of 1:3, adjusting the pH to 6.3, then adding 40 mg / ml magnetic carbon microspheres, and autoclaving for 20 minutes to obtain the culture medium;

[0044] The preparation method of described magnetic carbon microsphere is as follows:

[0045] (1) Dissolve waste bean dregs and potassium carbonate in distilled water at a mass ratio of 1:2, immerse at room temperature for 4 hours, then dry to a water content of 2%, and transfer to a tube furnace, under the protection of 400ml / min nitrogen, at 6 Heating at the rate of ℃ / min to 600 ℃, keeping it warm for 75 minutes, washing the sample until neutral after cooling...

Embodiment 2

[0059] A. Fresh shellfish is steamed, chopped, and placed in a -20°C refrigerator for freezing. After 6 hours, it is transferred to a vacuum freeze dryer, freeze-dried for 48 hours, and crushed through a 40-mesh sieve to obtain dried shellfish powder;

[0060] B. Add distilled water to the dry shellfish meat powder and carry out homogenization according to the ratio of material to liquid 1: 4, adjust the pH to be 7.0, then add 60mg / ml magnetic carbon microspheres, after autoclaving for 30min, obtain the culture medium;

[0061] The preparation method of described magnetic carbon microsphere is as follows:

[0062] (1) Dissolve waste bean dregs and potassium carbonate in distilled water at a mass ratio of 1:2, immerse at room temperature for 4 hours, then dry to a water content of 5%, and transfer to a tube furnace. Heat at a rate of ℃ / min to 650 ℃, keep warm for 100min, wash the sample until neutral after cooling, dry and grind into powder, and pass through a 100-mesh sieve to...

Embodiment 3

[0076] A. Fresh shellfish is steamed, chopped, and placed in a -20°C refrigerator for freezing. After 6 hours, it is transferred to a vacuum freeze dryer, freeze-dried for 48 hours, and crushed through a 40-mesh sieve to obtain dried shellfish powder;

[0077] B. adding distilled water to the dried shellfish meat powder for homogenization according to the ratio of material to liquid 4, adjusting the pH to 6.5, then adding 50 mg / ml magnetic carbon microspheres, and autoclaving for 30 minutes to obtain the culture medium;

[0078] The preparation method of described magnetic carbon microsphere is as follows:

[0079] (1) Dissolve waste bean dregs and potassium carbonate in distilled water at a mass ratio of 1:2, immerse at room temperature for 4 hours, then dry to a water content of 4%, and transfer to a tube furnace. Heat at a rate of ℃ / min to 600 ℃, keep it warm for 80 minutes, wash the sample until neutral after cooling, dry and grind it into powder, pass through a 80-mesh si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com