Laminated solar cell

A solar cell and stacking technology, applied in the field of solar cells, can solve the problems of high requirements for experimental equipment, high manufacturing costs, and high equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The present invention also provides a method for preparing the above laminated solar cell, comprising:

[0036] S1) Preparation of perovskite battery and cadmium telluride battery.

[0037] The perovskite battery is prepared according to the following steps: a hole transport layer is prepared on the conductive glass by a spin coating method; bromine-doped CH is prepared on the hole transport layer by a spray coating method or a spin coating method. 3 NH 3 PB 3 thin film; in the bromine-doped CH 3 NH 3 PB 3 A PCBM layer is prepared by a spin coating method on the thin film; a transparent electrode is prepared on the PCBM layer by a spray coating method to obtain a perovskite cell.

[0038] The cadmium telluride battery is prepared according to the following steps: a cadmium sulfide buffer layer is prepared on the conductive glass by a chemical water bath method or a magnetron sputtering method; a magnetron sputtering method or a near-space sublimation method is used...

Embodiment 1

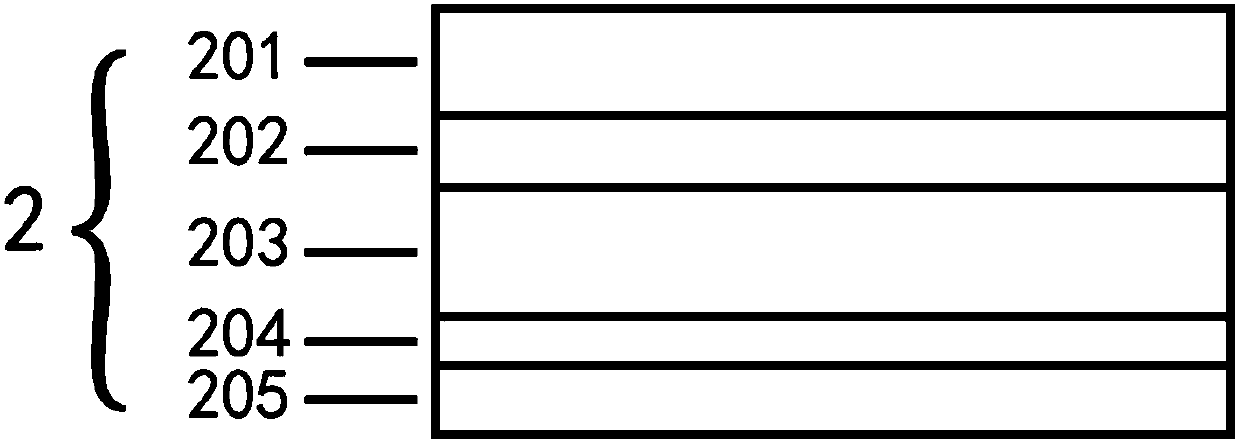

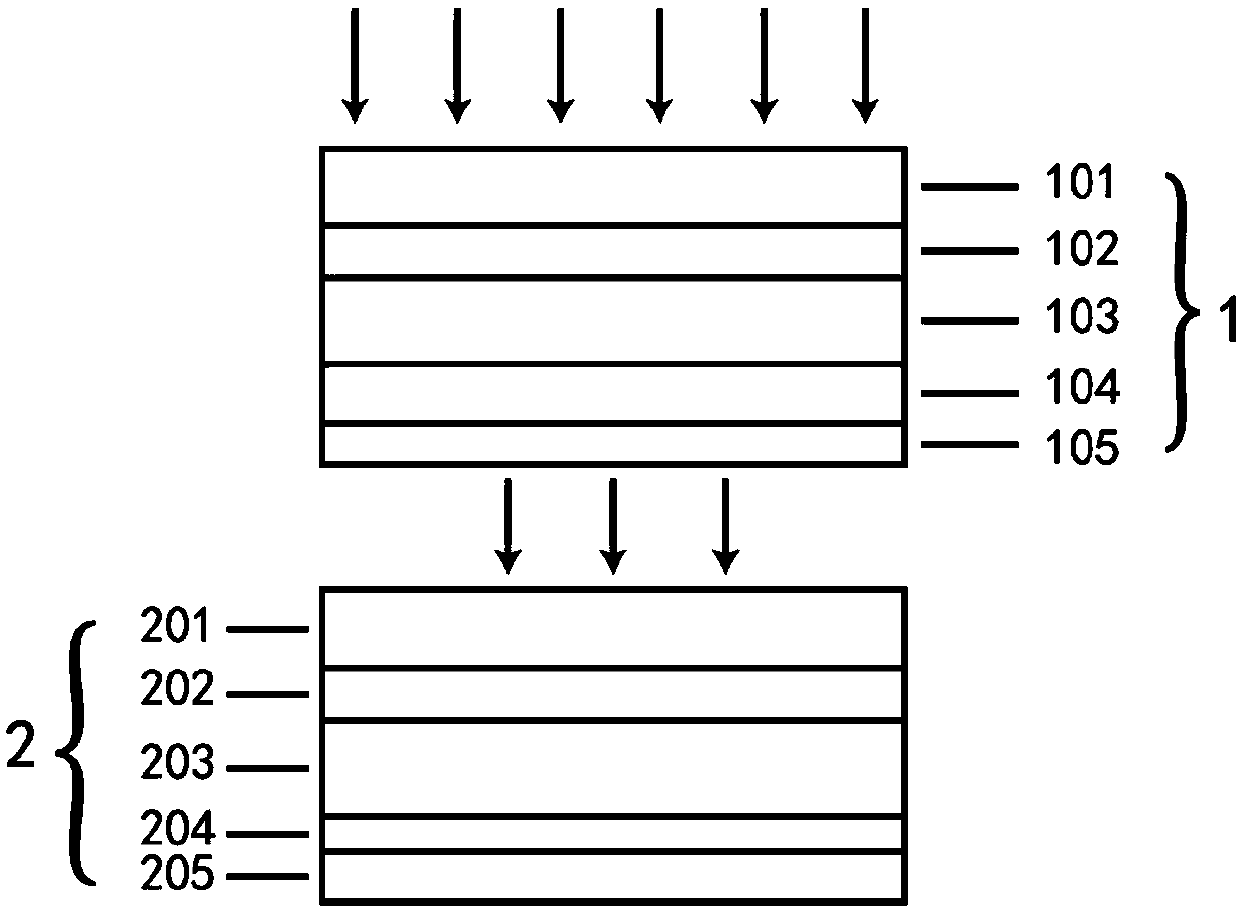

[0044] see figure 1 and figure 2 ; figure 1 is a schematic diagram of the structure of a cadmium telluride battery; figure 2 It is a schematic diagram of the structure of a tandem solar cell, in which 1 is a perovskite cell, 101 is a fluorine-doped tin dioxide FTO conductive glass, 102 is a PIF8-TAA hole transport layer, and 103 is a bromine-doped perovskite CH 3 NH 3 Pb(I 1-x Br x ) 3 layer, 104 is the PCBM electron transport layer, 105 is the silver nanowire layer; 2 is the cadmium telluride battery, 201 is the tin dioxide FTO conductive glass doped with fluorine, 202 is the CdS buffer layer, 203 is the CdTe absorption layer, 204 is Copper layer, 205 is a gold layer.

[0045] Preparation of perovskite battery 1:

[0046] (1) A PIF8-TAA hole transport layer 102 is prepared on the fluorine-doped tin dioxide FTO conductive glass 101 by spin coating method, with a thickness of 50-100 nm.

[0047] (2) Preparation of CH by spray coating or spin coating 3 NH 3 Pb(I 1-...

Embodiment 2

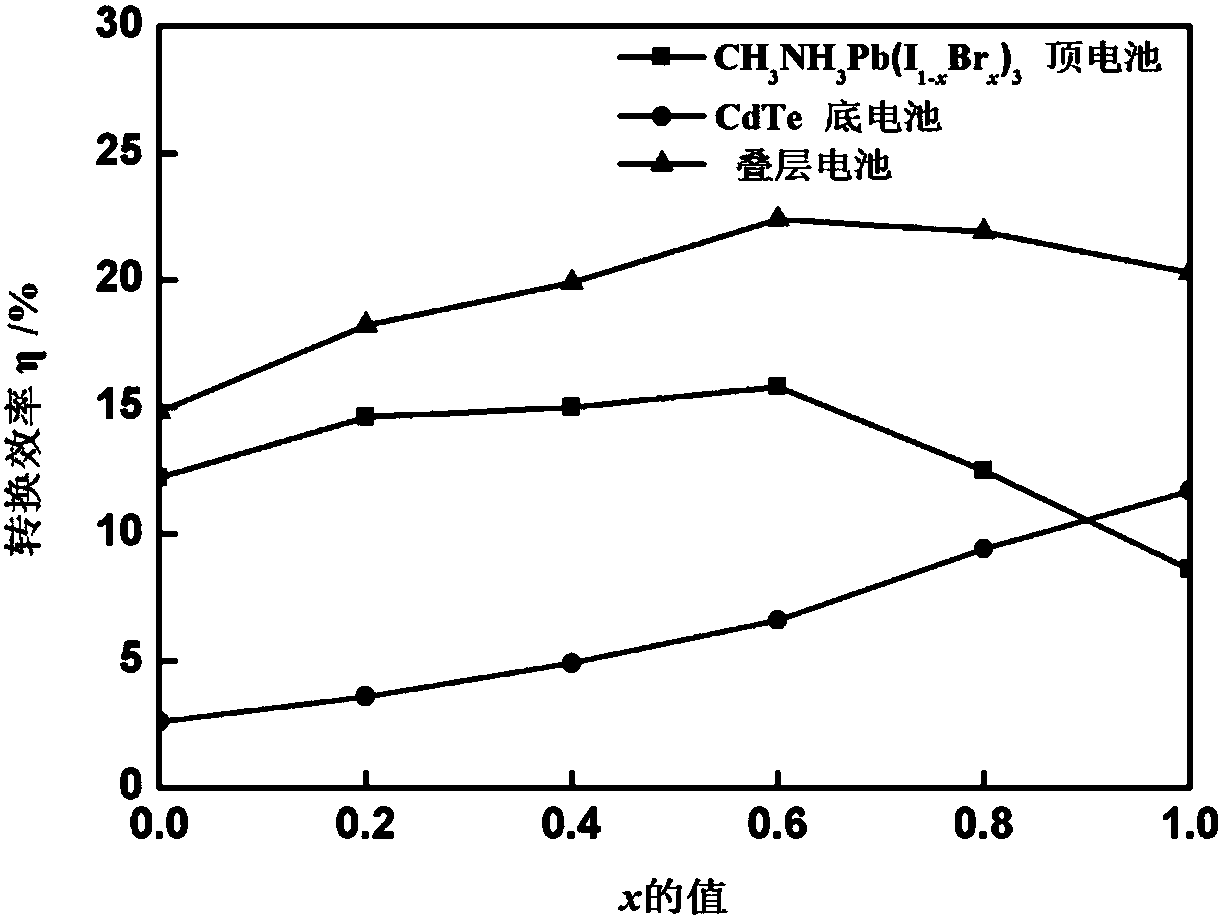

[0056] Laminated battery adopts figure 2 Shown CH 3 NH 3 Pb(I 1-x Br x ) 3 / CdTe stacked solar cell structure. In this structure, light from CH 3 NH 3 Pb(I 1-x Br x ) 3 When the top cell is incident, the shorter wavelength will be absorbed by the top cell to generate photogenerated carriers with higher energy, and the transmitted light will generate photogenerated carriers in the CdTe bottom cell, thus broadening the sensitivity of the two cells to sunlight. Absorb the wavelength range and improve the utilization rate of light.

[0057] in CH 3 NH 3 Pb(I 1-x Br x ) 3 In the top battery, in order to improve the transmittance of the battery, silver nanowires (AgNW) with good conductivity and transparency are selected as electrodes. The characteristic length of silver nanowires is 10-50 microns, the diameter is 20-50nm, and the thickness of silver nanowires is In the range of 100-150nm, the square resistance is 20-50 ohms per square, and the light transmittance i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com