Nano modified polysilazane anti-static material and preparation method thereof

A polysilazane, nano-modified technology, applied in conductive coatings, anti-corrosion coatings, fire-resistant coatings, etc., can solve the problems of low transparency and gloss, cannot be used in high temperature fields, and insufficient heat resistance, and can meet the requirements of equipment. High, convenient for large-scale industrialization, and low environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] A preparation method of nano-modified polysilazane antistatic material, the steps of which are:

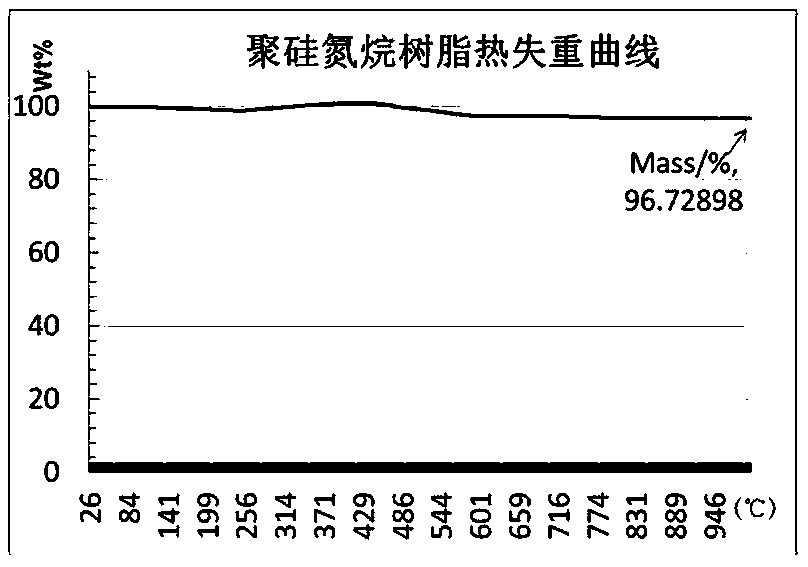

[0028] (1) Synthesis of polysilazane resin: use one or more of methyl chlorosilane and methyl trichlorosilane chlorosilane raw materials to react with ammonia gas or liquid ammonia for several hours at low temperature, filter out the ammonium chloride precipitate, The solvent is distilled off under reduced pressure to obtain polysilazane resin;

[0029] (2) Preparation of ATO dispersion liquid: first grind and disperse the nano-ATO powder, dispersant, coupling agent, and solvent in a ball mill or other nano-particle dispersing grinder according to a certain ratio, and the grinding time is 0.5-12h to obtain a nano-ATO dispersion Liquid, sieve out the nanoparticle dispersion liquid whose particle size meets the requirements of 5-200 nanometers;

[0030] (3) Preparation of functional modifier slurry: Add functional modifiers (such as titanium dioxide, zinc phosphate, magnesiu...

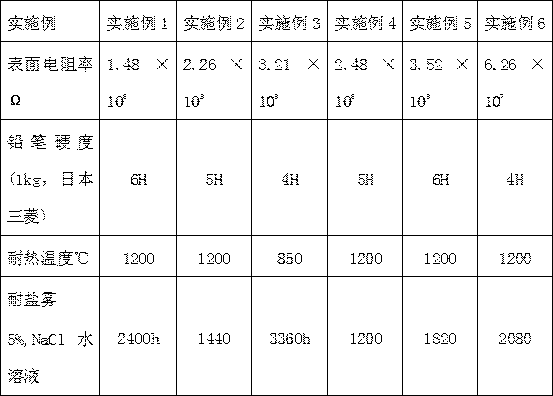

Embodiment 1

[0037] Example 1: A nano-modified polysilazane antistatic material, comprising the following components by weight ratio: polysilazane resin 50%, nano-ATO 30%, coupling agent KH560 0.5%, functional modifier 0%, dispersant 24000 0.5%, thixotropic agent 0%, butyl acetate 19%.

[0038] The preparation method is as follows: add ATO powder with a particle size distribution of 10nm-50nm, coupling agent KH560, dispersant 24000, and butyl acetate into a ball mill according to the corresponding proportion, grind for 3-8 hours, and detect the concentration of nanoparticles in the solvent system. Dispersion, until the particle size distribution is uniform, filter to obtain a nano-ATO dispersion, the solid content is controlled above 30%; mix polysilazane resin and ATO dispersion according to the proportion, and disperse for 0.5-1h with a high-speed disperser to obtain Nano-ATO modified polysilazane high temperature resistant and high antistatic material.

Embodiment 2

[0039] Example 2: A nano-modified polysilazane antistatic material, comprising the following components by weight ratio: polysilazane resin 50%, nano-ATO 20%, coupling agent KH560 0.3%, titanium dioxide 10% , dispersant 24000 0.7%, thixotropic agent 0%, butyl acetate 19%.

[0040] The preparation method is as follows: add ATO powder with a particle size distribution of 10nm-50nm, coupling agent KH560, dispersant 24000, and butyl acetate into a ball mill according to the corresponding proportion, grind for 3-8 hours, and detect the concentration of nanoparticles in the solvent system. Dispersion, until the particle size distribution is uniform, filter to obtain nano-ATO dispersion liquid, the solid content is controlled above 30%; disperse and grind titanium dioxide, dispersant 24000, and butyl acetate in a ball mill for 2 hours to obtain nano-titanium dioxide with a certain solid content Color paste: mix polysilazane resin, ATO dispersion liquid, nano-titanium dioxide color pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com