Preparation method and application of analgesic bioactive glass powder

A bioactive glass and powder technology, which is applied in powder delivery, inorganic active ingredients, non-central analgesics, etc., can solve the problems of difficult long-term attachment of active ingredients, poor taste, slow onset of action, etc., and achieve the effect of inhibiting bacteria The effect of growth, stable product quality and good surface stickiness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

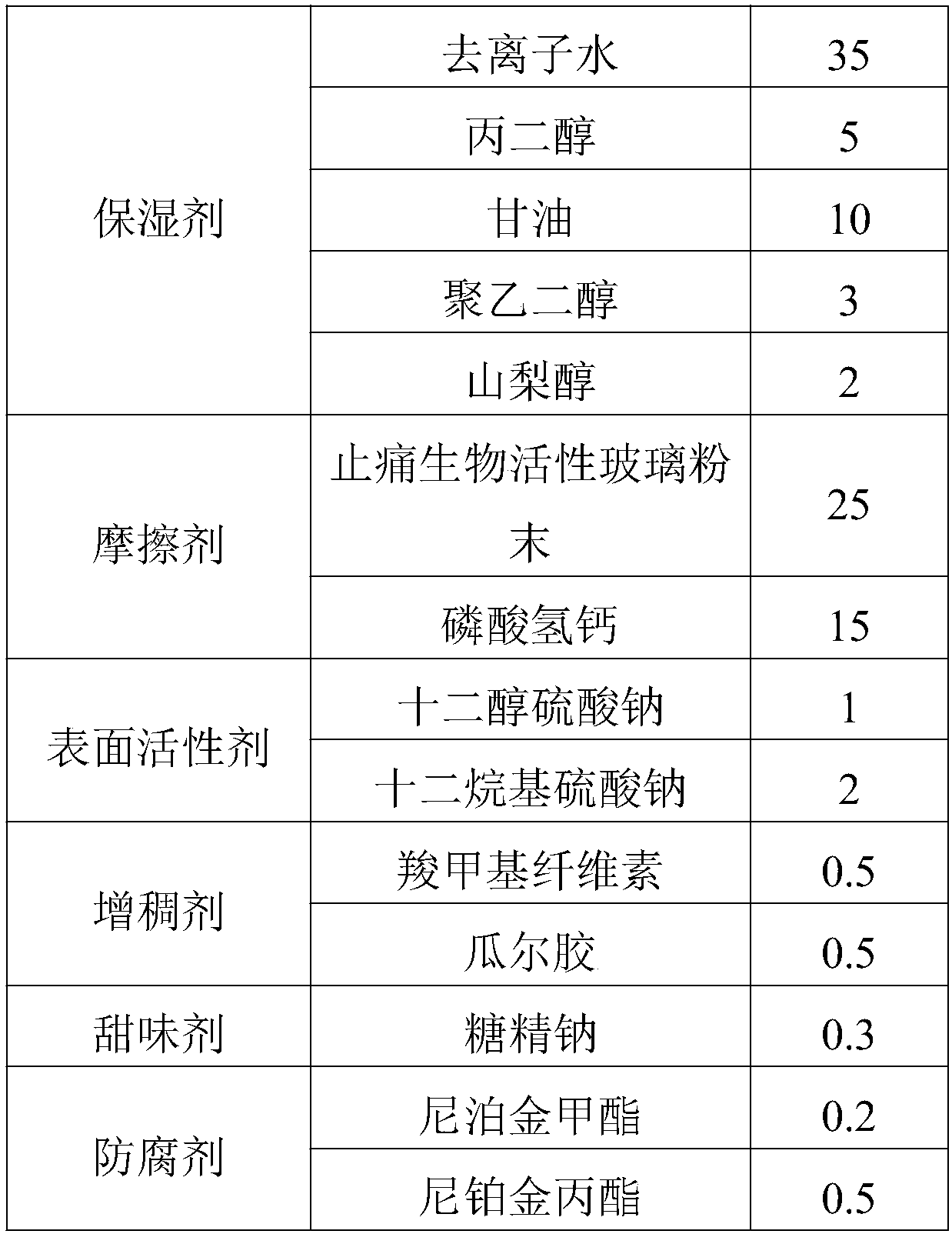

Embodiment 1

[0045] A preparation method of analgesic bioactive glass powder provided in this embodiment comprises the following steps:

[0046] (1) the concentrated nitric acid of 6ml 69wt.% is dispersed in 250ml deionized water, stirs, obtains dilute nitric acid;

[0047] (2) Get 125g ethyl orthosilicate and dissolve in dilute nitric acid, stir and hydrolyze for 1.5 hours;

[0048] (3) 10g of triethyl phosphate was dissolved in the solution obtained in step (2), stirred and hydrolyzed for 0.8 hours;

[0049] (4) Get 62.5g calcium nitrate tetrahydrate and be dissolved in the solution gained in step (3), stir and hydrolyze for 15 minutes;

[0050] (5) Get 700g sodium nitrate, be dissolved in the solution gained in step (4), stir and hydrolyze for 30 minutes;

[0051] (6) Place the solution obtained in step (5) at room temperature to age for 20 hours, the solution gradually forms a gel, and continue to age the gel at 60-70°C for 20 hours;

[0052] (7) drying the gel obtained in step (6) at...

Embodiment 2

[0059] A preparation method of analgesic bioactive glass powder provided in this embodiment comprises the following steps:

[0060] (1) disperse the concentrated nitric acid of 8ml 69wt.% in 250ml deionized water, stir, obtain dilute nitric acid;

[0061] (2) Get 160g ethyl orthosilicate and dissolve in dilute nitric acid, stir and hydrolyze for 0.5 hour;

[0062] (3) 14g of triethyl phosphate was dissolved in the solution obtained in step (2), stirred and hydrolyzed for 0.6 hour;

[0063] (4) Get 54g calcium nitrate tetrahydrate and be dissolved in the solution gained in step (3), stir and hydrolyze for 5 minutes;

[0064] (5) Get 300g sodium nitrate and 300g potassium nitrate, be dissolved in the solution gained in step (4), stir and hydrolyze for 20 minutes;

[0065] (5.1) Get 15g citric acid and be dissolved in the solution gained in step (5), stir and hydrolyze for 15 minutes;

[0066] (6) Place the solution obtained in step (5) at room temperature to age for 15 hours,...

Embodiment 3

[0074] This embodiment provides a method for preparing analgesic bioactive glass powder, comprising the following steps:

[0075] (1) the concentrated nitric acid of 10ml 69wt.% is dispersed in 250ml deionized water, stirs, obtains dilute nitric acid;

[0076] (2) Get 195g ethyl orthosilicate and dissolve in dilute nitric acid, stir and hydrolyze for 2 hours;

[0077] (3) 18g of triethyl phosphate was dissolved in the solution obtained in step (2), stirred and hydrolyzed for 0.7 hours;

[0078] (4) Get 105.5g calcium nitrate tetrahydrate and be dissolved in the solution gained in step (3), stir and hydrolyze for 12 minutes;

[0079] (5) Get 500g sodium nitrate and 100g potassium nitrate, be dissolved in the solution gained in step (4), stir and hydrolyze for 5 minutes;

[0080] (6) Place the solution obtained in step (5) at room temperature to age for 24 hours, the solution gradually forms a gel, and continue to age the gel at 60-70°C for 24 hours;

[0081] (7) drying the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com