A method for highly selective extraction of polysaccharides from mugwort

A high-selectivity, polysaccharide technology, applied in the production of bulk chemicals, can solve problems such as complicated processes, and achieve the effects of high extraction selectivity, high product purity, and shortened extraction time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

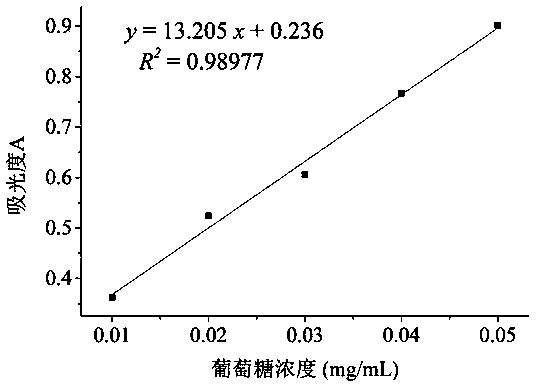

[0029] Embodiment 1, the making of standard curve of glucose and the detection method of polysaccharide

[0030] Use the phenol-sulfuric acid method to detect polysaccharides. First, draw a glucose standard curve: take the glucose standard product dried to constant weight at 105°C to prepare a mother solution with a concentration of 0.1 mg / mL, and perform stepwise dilution to prepare a final concentration of 0.01. , 0.02, 0.03, 0.04 and 0.05 mg / mL standard solutions; each take 2 mL of standard solutions of different concentrations, add 1 mL of 5% phenol solution and 5 mL of concentrated sulfuric acid in turn, mix well, and boil in water bath for 10 min, take out and Cool to room temperature, use distilled water as a blank, measure the absorbance at 490 nm, and record the data; take the glucose standard solution concentration as the abscissa, and the absorbance OD490 as the ordinate to make a standard curve ( figure 2 ), and fit the regression equation:

[0031] Y =13.205 x...

Embodiment 2

[0035] Example 2, traditional water extraction and alcohol precipitation method for polysaccharide extraction

[0036] Based on literature reports (Shen Xia, Zhang Yanhong, Yuan Huihui, et al. Optimization of Extraction Process of Artemisia argyi Folium Polysaccharides by Response Surface Method [J]. Chinese Patent Medicine, 2010, 32(1):48-51.) Optimized by Response Surface Method The optimal conditions for the extraction of crude polysaccharides from Artemisia argyi leaves were to extract polysaccharides from Artemisia argyi: the extraction temperature was 99°C, the extraction time was 2.3 h, and the ratio of water to material was 20. After the extraction, the extract was centrifuged at 5000 rpm for 15 min; the supernatant after centrifugation was concentrated under reduced pressure, and 4 times the volume of 95% ethanol solution was added, and placed in a refrigerator at 4 °C for 4 h. The polysaccharide is completely precipitated, and then filtered and freeze-dried to obtain...

Embodiment 3

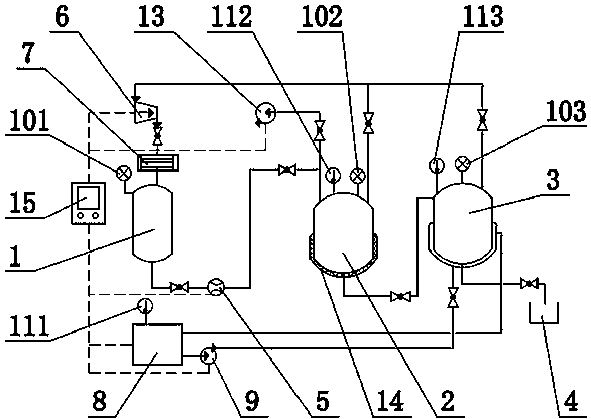

[0038] Embodiment 3, the method used in the present invention extracts the polysaccharide of northern mugwort

[0039] Grind the leaves of Artemisia argyi with a water content lower than 8% and pass through a 40-mesh sieve, take 100 g and place them in an extraction tank, vacuumize until the vacuum degree in the extraction tank reaches -100 kPa, inject distilled water into the extraction tank as an extraction solvent, and Artemisia argyi samples were completely submerged, the mass volume ratio of leaves and distilled water was 1:8 g / ml, and the entrainer for extraction was [C 4 mim]Cl ionic liquid 8 g, the extraction temperature was controlled at 110°C by the automatic controller and the far-infrared generator at the bottom of the extraction tank, the far-infrared power was 1000 W, the wavelength range was 25-200 μm, the extraction pressure was 0.15 Mpa, and the extraction time 6 minutes, 2 times of circular extraction; after the extraction, the liquid solvent is pumped into t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com