Polypeptide electrode, supercapacitor prepared therefrom and preparation method thereof

An electrode and polypeptide technology, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve the problems of poor stability and cycle performance of electric double layer capacitors, achieve good application prospects, improve rate performance, good The effect of foldable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

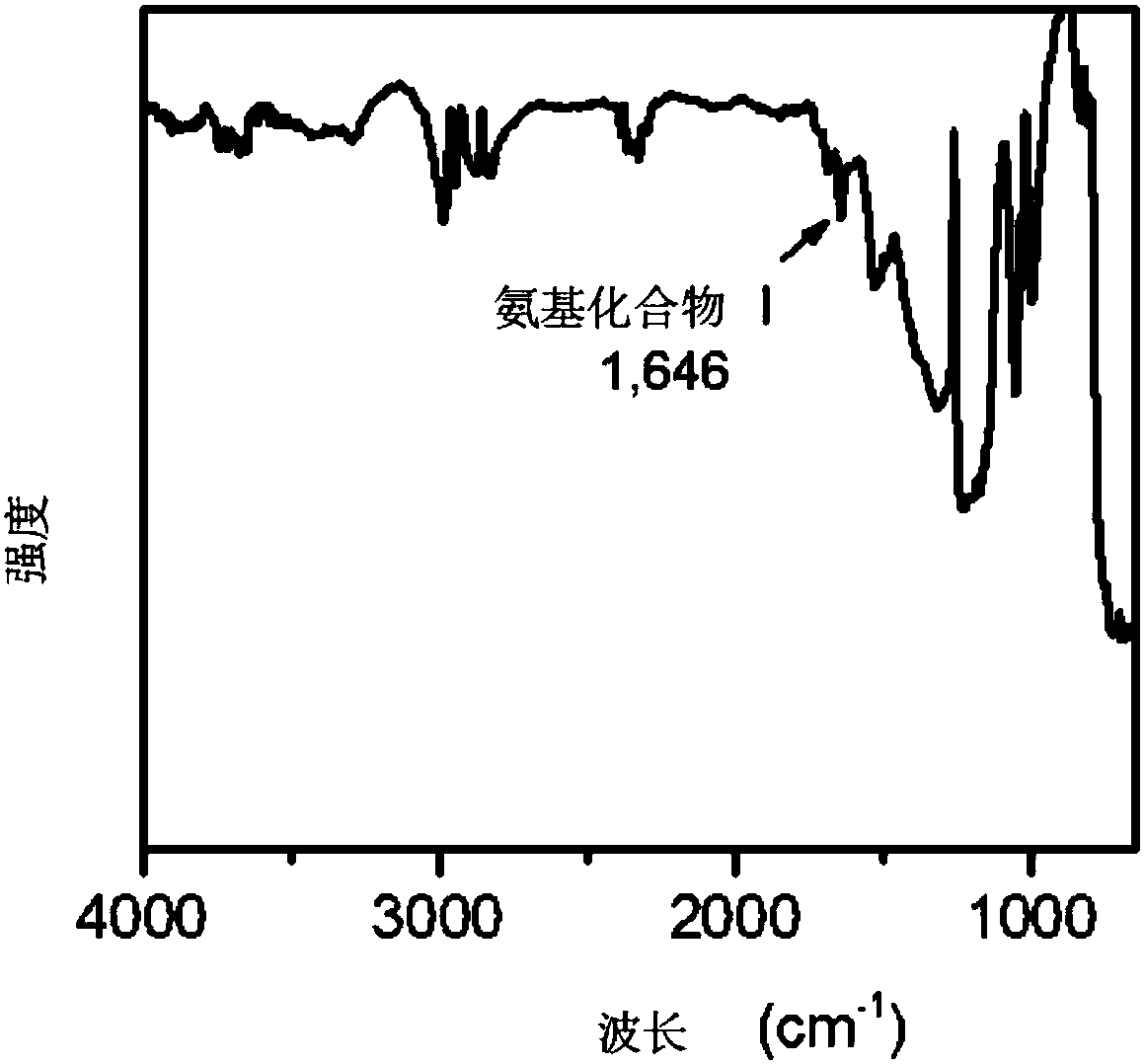

[0041]Example 1: Preparation and Characterization of Polypeptide Nanofibers

[0042] Polypeptides are synthesized by solid-phase peptide synthesis as electrode materials for polypeptide supercapacitors. The polypeptides are dipeptides, and their molecular structural formula is:

[0043]

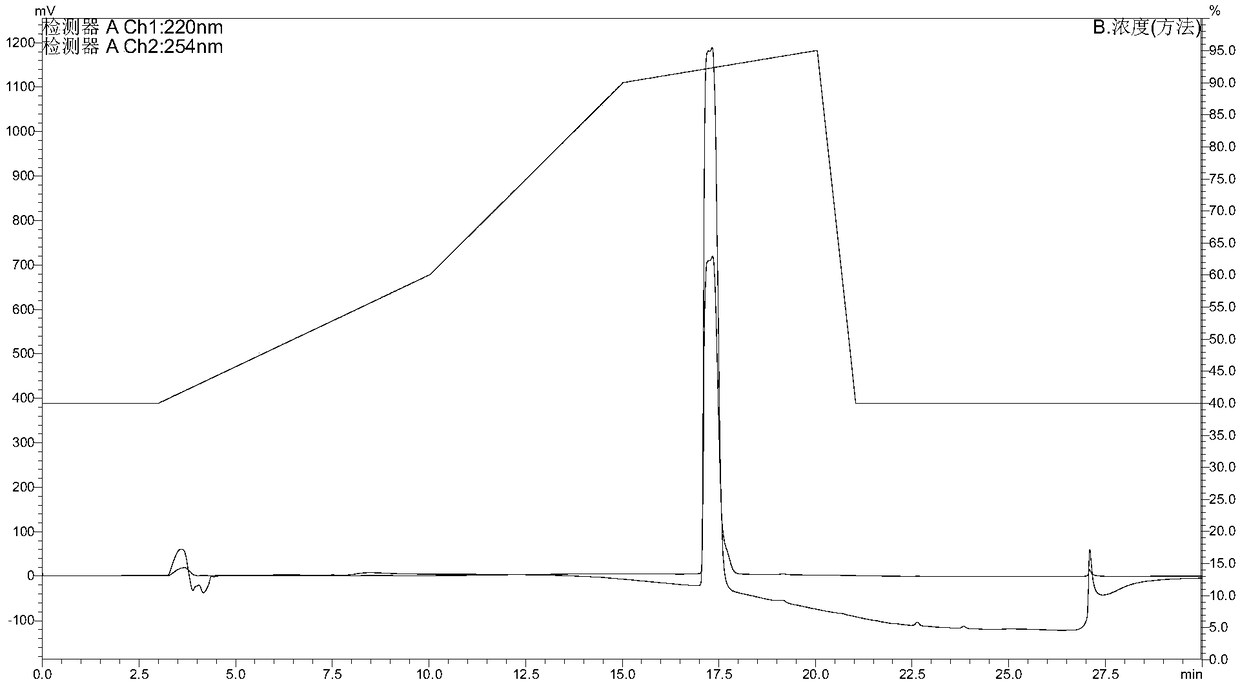

[0044] The synthesis steps include: linking the natural amino acid phenylalanine (F) to the resin by a polypeptide solid-phase synthesis method, and then linking the carboxyl end of the natural amino acid glutamic acid (E) at the amino terminal of F, so that F and E are connected, The amino terminal of E is protected by Fmoc connection, and then the dipeptide molecule is cut off from the resin, separated and purified by high-performance liquid chromatography, and freeze-dried to obtain the above-mentioned dipeptide. The flow of this process is as follows:

[0045]

[0046] In the above synthesis process, the equivalents used for raw materials are: the degree of substitution of resin: 0...

Embodiment 2

[0051] Example 2: Preparation of Polypeptide Electrode

[0052] (1) Preparation of conductive substrate: select a polyethylene terephthalate (PET) film 1 with a thickness of 0.1 mm as the substrate, and sputter a layer of gold atoms on the PET film 1 with a magnetron sputtering apparatus to form a Layer thickness is about the gold film 2 of 5nm, makes the conductive base of electrode thus (referring to Figure 4 ). A multimeter was used to detect the conductivity of the prepared conductive substrate.

[0053] (2) Formation of polypeptide nanofiber layer 3: the gel-like polypeptide dispersion prepared in Example 1 is evenly coated on the conductive substrate, placed in a ventilated place to dry, and after the moisture is volatilized, it is transferred to Water removal treatment was carried out in a vacuum oven at 60°C. In the above process, the polypeptide grows in the form of self-assembly on the surface of the conductive substrate, and a network-like polypeptide nanofiber ...

Embodiment 3

[0055] Embodiment 3: the preparation of polypeptide supercapacitor

[0056] (1) Preparation of electrolyte: Add 10 g of deionized water and 1 g of concentrated sulfuric acid (H 2 SO 4 , analytically pure, mass fraction 98%), stir evenly; add 1g of polyvinyl alcohol crystals (PVA, analytically pure) to the above solution, stir evenly; place the beaker containing the mixed solution obtained above in a stirring water bath at 90°C In the pot, stir at a speed of 200r / min, and keep warm for 30min to get transparent and uniform PVA+H 2 SO 4 The electrolyte solution was kept warm in a water bath at 90°C until use.

[0057] (2) The polypeptide electrode was prepared by the method described in Example 2.

[0058] (3) The assembly of supercapacitor: the PVA+H that step (1) makes 2 SO 4 The electrolytic solution and the polypeptide electrode prepared in step (2) are assembled and compacted in an electric double layer capacitor, and finally a formed supercapacitor is formed. The thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com