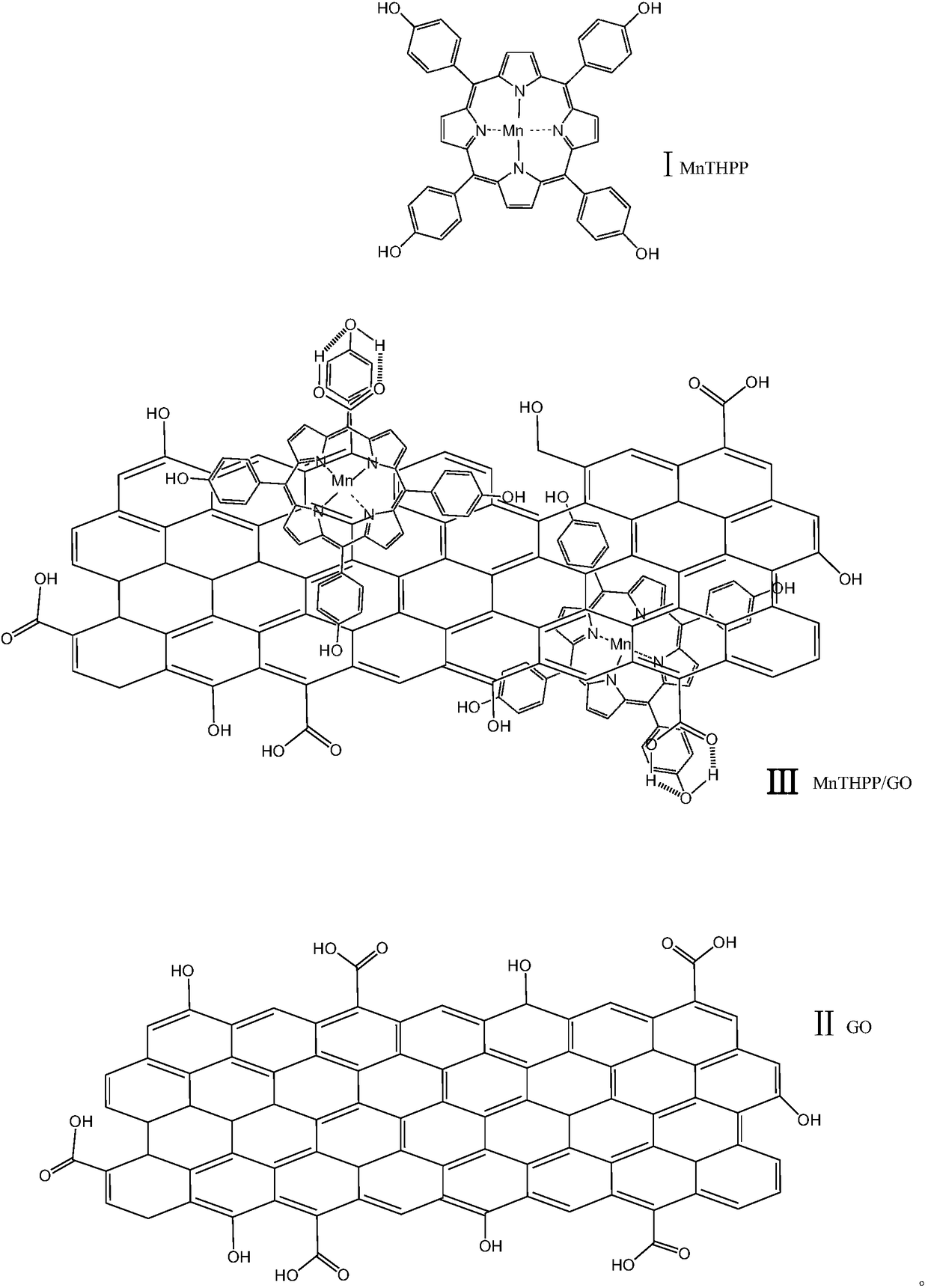

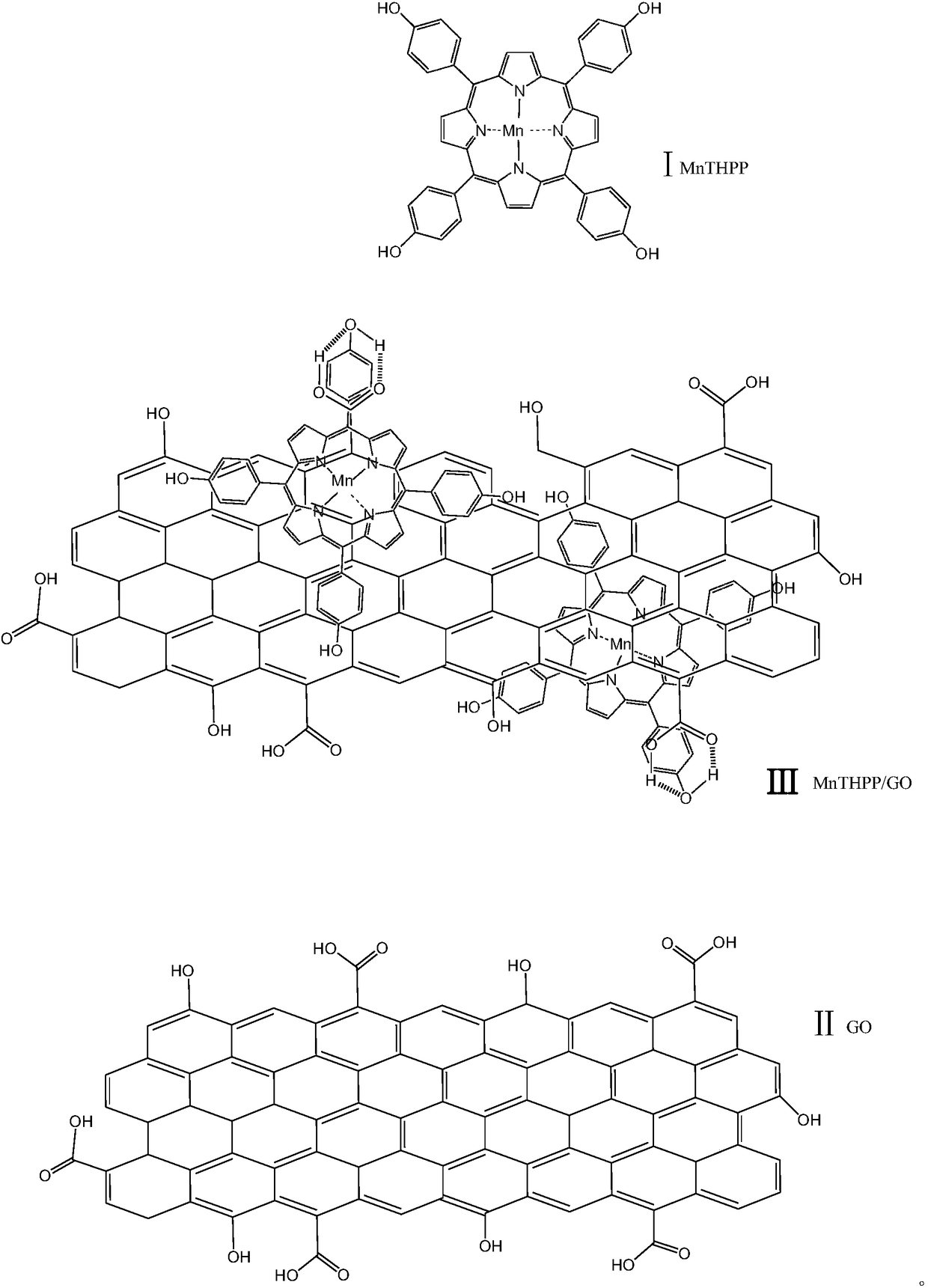

Preparation method and catalytic application of graphene oxide immobilized tetra(4-hydroxyphenyl) manganese porphyrin catalytic material

A porphyrin catalytic material and hydroxyphenyl technology are applied in the field of preparation of graphene oxide-immobilized tetramanganese porphyrin catalytic materials, and can solve the problem of inconvenient recycling, low catalytic oxidation efficiency of ethylbenzene, and low catalytic efficiency of metal porphyrins. and other problems, to achieve the effect of environmental protection recycling, easy recycling and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

[0024] The preparation method of described graphene oxide immobilized tetrakis (4-hydroxyphenyl) manganese porphyrin catalytic material is made up of the following steps:

[0025] (1) Preparation of graphite oxide: Add 200 parts of concentrated sulfuric acid into a three-necked flask, put it in a cold trap and keep it for five minutes, then add 8 parts of graphite powder and 4 parts of sodium nitrate, let it react for 30 minutes, then slowly add high manganese 30 parts of potassium acid potassium, after reacting for 1 hour, take it out, wait for room temperature, continue to react in a water bath at 35°C for 1 hour, then add 500 parts of distilled water, continue to slowly add 150 parts of 5% hydrogen peroxide until the liquid turns yellow, and let it stand for stratification , remove the supernatant, wash with 1000 parts of 5% hydrochloric acid for several times until no sulfate ions are detected, and dry at 60°C for 48 hours to obtain graphite oxide;

[0026] (2) Preparation...

preparation Embodiment 2

[0029] The preparation method of described graphene oxide immobilized tetrakis (4-hydroxyphenyl) manganese porphyrin catalytic material is made up of the following steps:

[0030] (1) Preparation of graphite oxide: Add 250 parts of concentrated sulfuric acid into a three-necked flask, put it in a cold trap and keep it for five minutes, then add 10 parts of graphite powder and 5 parts of sodium nitrate, let it react for 30 minutes, then slowly add high manganese 38 parts of potassium acid potassium, after reacting for 1 hour, take it out, wait for room temperature, continue to react in a 35°C water bath for 1 hour, then add 625 distilled water, continue to slowly add 200 parts of 5% hydrogen peroxide until the liquid turns yellow, and let it stand for stratification. Remove the supernatant, wash with 1250 parts of 5% hydrochloric acid for several times until no sulfate ion is detected, and dry at 60°C for 48 hours to obtain graphite oxide;

[0031] (2) Preparation of graphene o...

preparation Embodiment 3

[0034] The preparation method of described graphene oxide immobilized tetrakis (4-hydroxyphenyl) manganese porphyrin catalytic material is made up of the following steps:

[0035](1) Preparation of graphite oxide: Add 300 parts of concentrated sulfuric acid into a three-necked flask, put it in a cold trap and keep it for five minutes, then add 12 parts of graphite powder and 6 parts of sodium nitrate, make it react for 30 minutes, then slowly add high manganese 45 parts of potassium acid potassium, after reacting for 1 hour, take it out, wait for room temperature, continue to react in a water bath at 35°C for 1 hour, then add 750 parts of distilled water, continue to slowly add 250 parts of 5% hydrogen peroxide until the liquid turns yellow, and let it stand for stratification , remove the supernatant, wash with 1500 parts of 5% hydrochloric acid for several times until no sulfate ion is detected, and dry at 60°C for 48 hours to obtain graphite oxide;

[0036] (2) Preparation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Aperture size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com