Kluyveromyces lactis mutant strain as well as glycosidase and application thereof

A Kluyveromyces and glycosidase technology, applied in the field of Kluyveromyces lactis mutant strains, can solve the problems of catalytic efficiency, substrate range high-temperature activity and stability, unsatisfactory yield, glycosidase safety and poor activity, etc. problems, to achieve the effects of reduced bacterial contamination, high safety, and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Compound mutagenesis of embodiment 1 Kluyveromyces lactis strain ATCC 8585

[0067] 1.1 Preparation of Kluyveromyces lactis ATCC 8585 single colony

[0068] The preserved Kluyveromyces lactis ATCC 8585 was inoculated into YPD liquid medium, and cultured continuously at 28° C. and 250 rpm for 2 to 3 days. Dilute the fermentation broth 10 with sterile water -3 , 10 -4 , 10 -5 After doubling, spread them on the YPD solid medium plate, culture statically at 28°C for 2 to 3 days, after a single colony grows, pick a single colony and transfer it to the YPD liquid medium, continuously culture at 28°C, 250rpm for 48 Hour.

[0069] 1.2 UV treatment

[0070] After the cultivation, the bacterial solution was diluted with sterile physiological saline so that the yeast cell concentration was about 10 7 pieces / ml. Take 25ml of bacterial solution and place it in a sterile empty plate, and carry out medium-speed magnetic stirring. Irradiate for 1min, 2min, 3min, 4min and 5min r...

Embodiment 2

[0077] Example 2 Screening of Kluyveromyces lactis Mutants

[0078] 2.1 Cultivation of mutant strains

[0079] Pick the clones on the plate in 1.5 and transfer them to a 96-deep well plate containing 1ml YPD liquid medium. Continuous culture was carried out at 30°C and 250 rpm for 5 days. After the incubation, the deep-well plate was centrifuged at 5000 rpm for 5 min. Take 100 μl of fermentation broth into a 96 shallow-well plate and store it at 4°C until use.

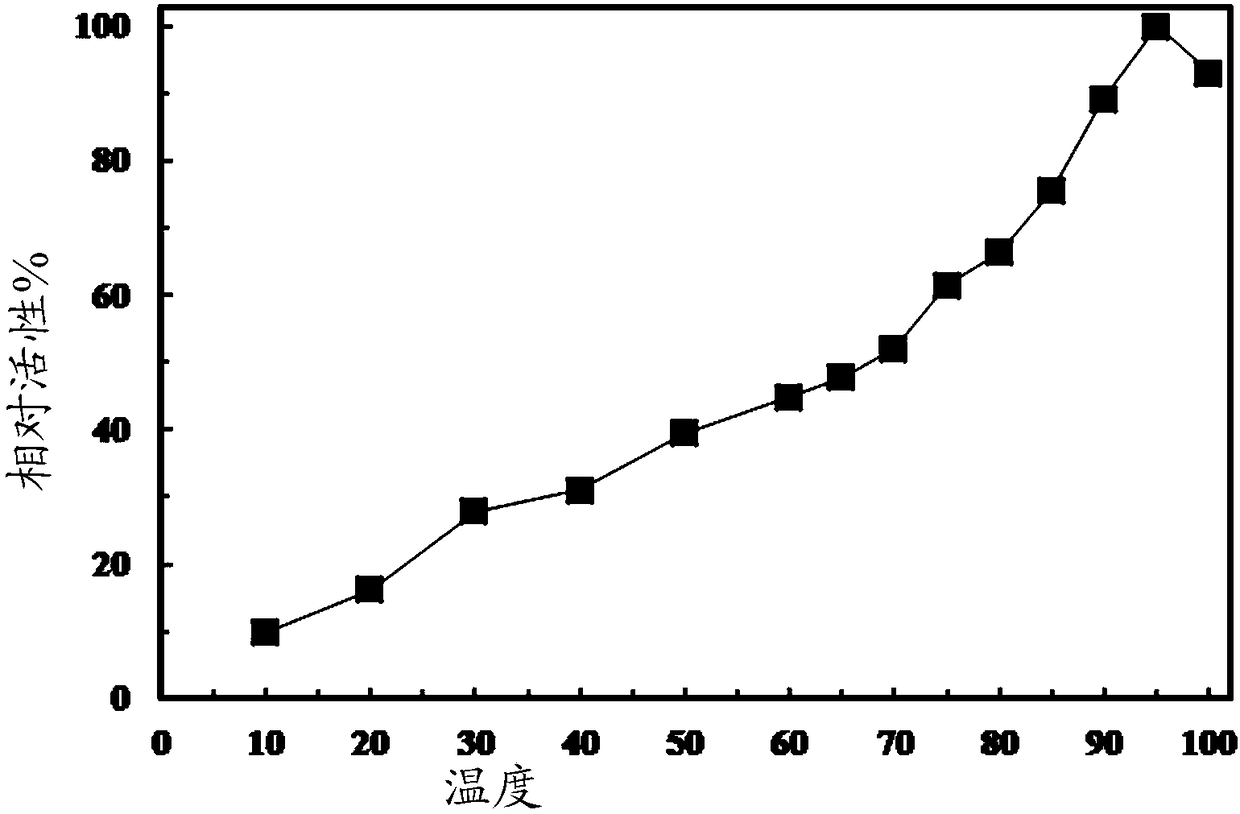

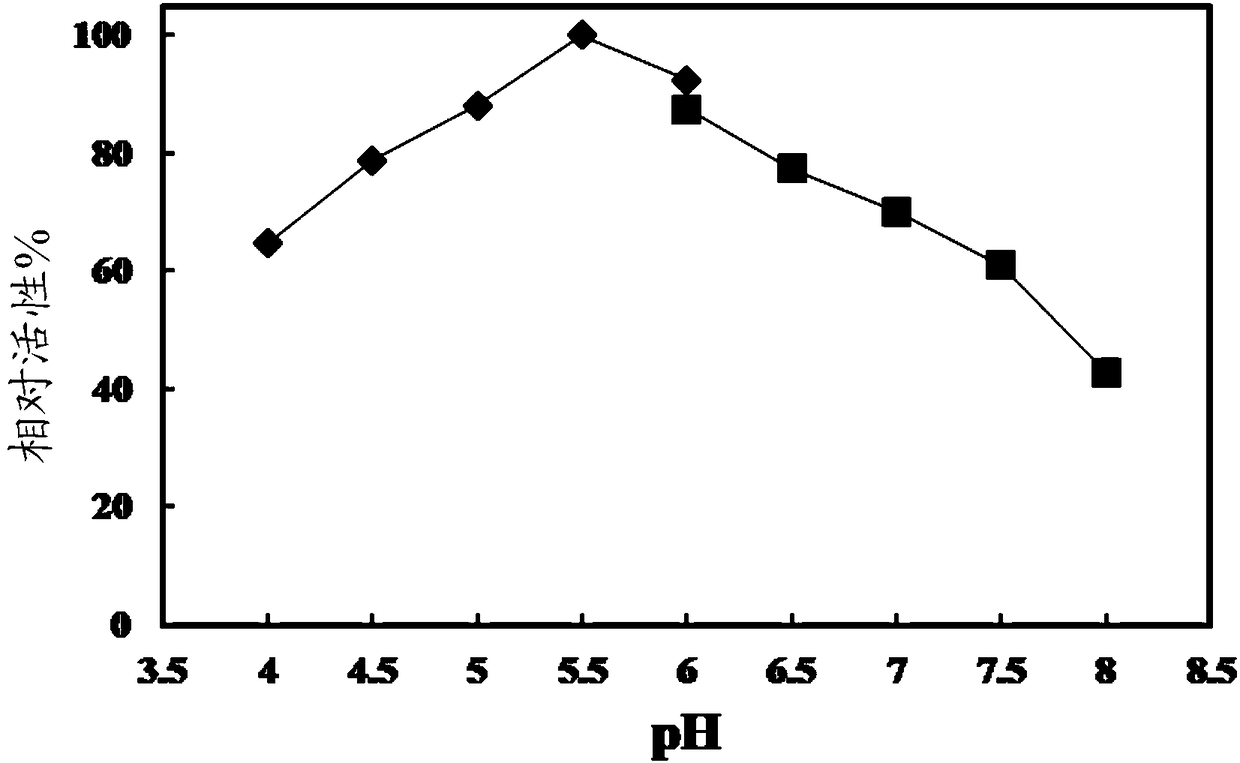

[0080] 2.2 Determination of glycosidase activity of mutant strains

[0081] The fermentation broth obtained in 2.1 was incubated at 95°C for 30 minutes, centrifuged at 10,000 rpm for 10 minutes, and the supernatant was collected. The assay was carried out with p-nitrophenol β-D-glucoside (pNPG) as the substrate. The system for measuring activity is: sodium phosphate buffer 0.05ml (100mM, pH7.0) + 0.05ml enzyme solution to be tested + 15μl pNPG (100mM, dissolved in DMSO), with no enzyme solution as the blank contro...

Embodiment 3

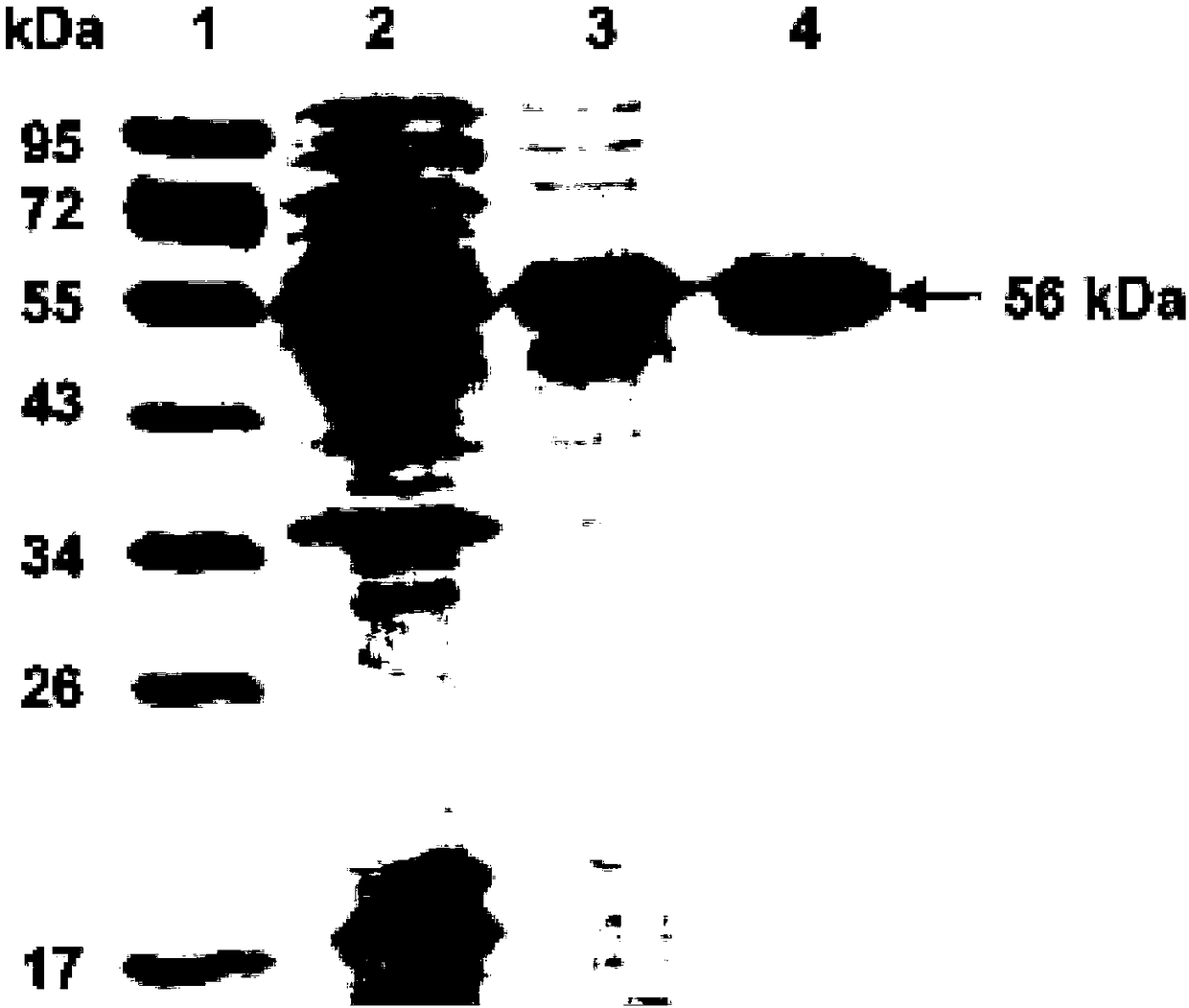

[0084] Example 3 Obtaining of Kluyveromyces lactis XT1412 glycosidase

[0085] 3.1 Fermentation production

[0086] Kluyveromyces lactis XT1412 preserved in 2.3 was activated with 100 ml of liquid YPD medium, and cultured continuously at 28° C. and 250 rpm for 2 days. After the culture was completed, the microscopic observation showed that there was no bacterial contamination, and then transferred to a 5L fermenter of liquid YPD medium, and fermented continuously for 5 days at 28° C. and 300 rpm. After the fermentation, the cells were collected by centrifugation at 5000 rpm for 10 min. Suspend cells in 500ml sterile 50mM pH7.0Na 2 HPO 4 / NaH 2 PO 4 In the buffer solution, use a high-pressure homogenizer to break the cells at 0°C and 1000MPa. After the cells were broken, they were centrifuged at 5000rpm for 20min, the supernatant was collected, and incubated at 95°C for 20min. Centrifuge again at 5000rpm for 10min, collect the supernatant, and store at 4°C.

[0087] 3.2 A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com