Preparation method of a hierarchically porous metal-organic framework nanomaterial with adjustable pore size, nanomaterial obtained therefrom and its application

A metal-organic framework, nanomaterial technology, applied in the field of porous materials and enzyme immobilization, can solve the problems of poor chemical stability and thermal stability, reduced porosity and specific surface area, poor stability of MOFs, etc., to achieve good cycle performance, effective The effect of fixed, efficient catalytic capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

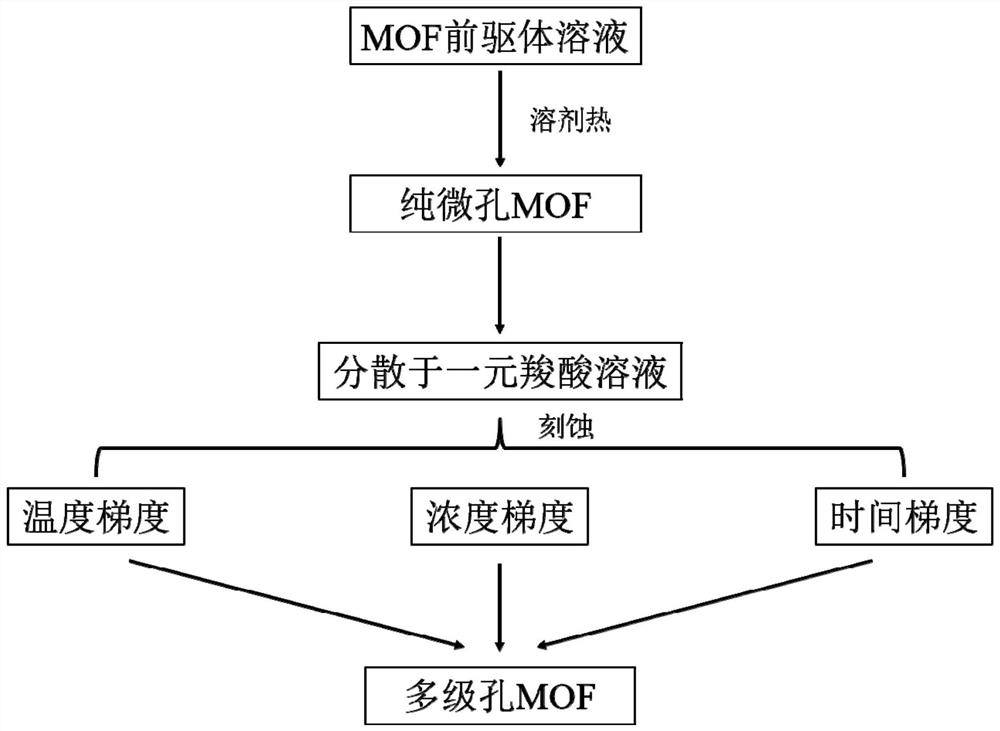

[0058] Such as figure 1 As shown, at room temperature,

[0059] a. Dissolve 4 millimoles of zirconium tetrachloride in 72ml N, N dimethylformamide (DMF), then add 80 millimoles of benzoic acid as an organic ligand, add terephthalic acid and 660 microliters after dissolving Concentrated hydrochloric acid (mass fraction 37%), after ultrasonic 30min, leave standstill in 120 ℃ oven for 24 hours;

[0060] b. Centrifuge the material cooled to room temperature, wash with DMF three times, disperse in acetone to replace DMF, replace for three days, and replace acetone every 12 hours. Then vacuum-dried at 100°C for 24 hours to obtain a microporous zirconium-based metal-organic framework (micro-UiO-66);

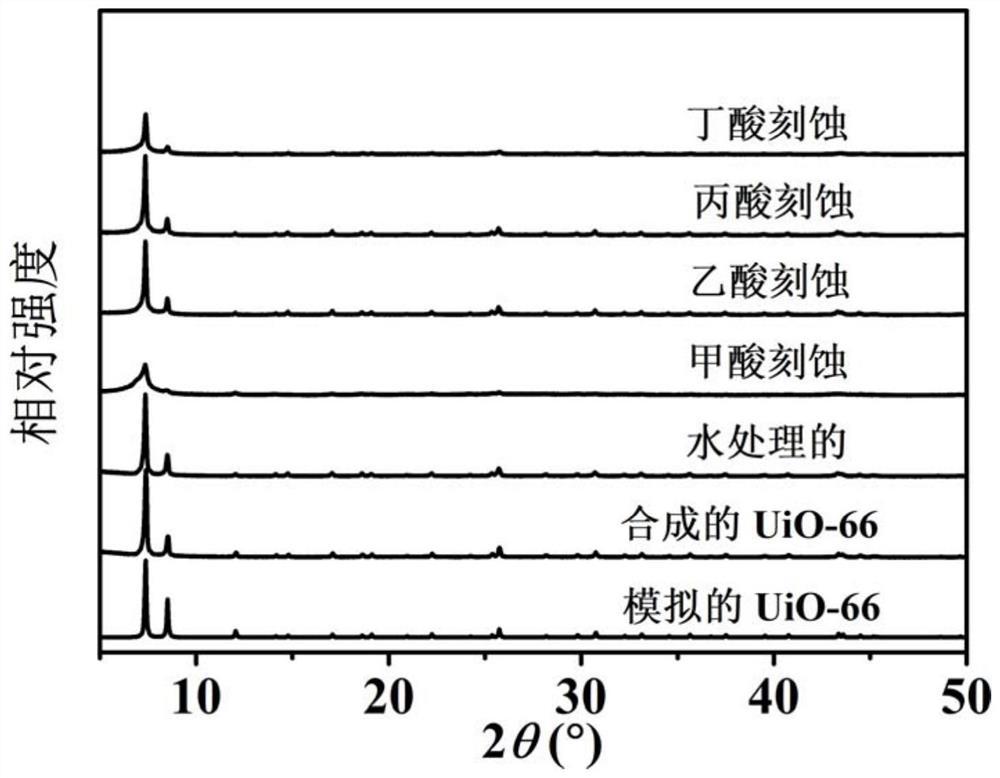

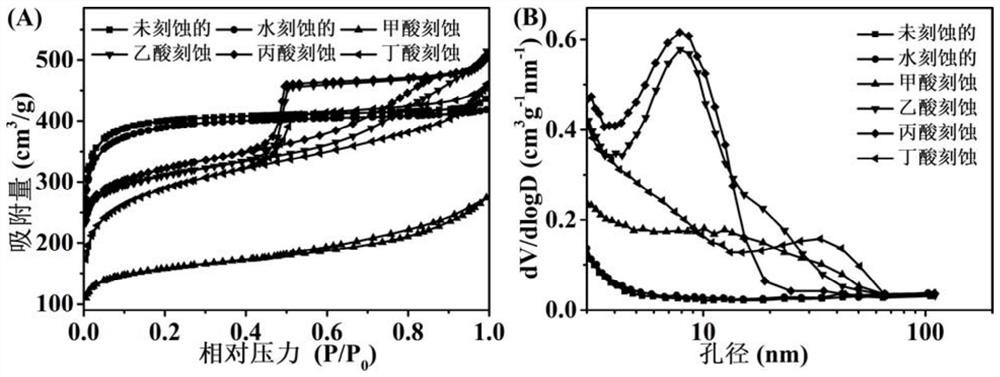

[0061] c. Disperse 100 mg of microporous zirconium-based metal-organic framework (micro-UiO-66) in 1.6 mol / L of different monocarboxylic acid (formic acid FA, acetic acid AA, propionic acid PA and butyric acid BA) solutions, and stand at 100 ° C for 6 Hours later, wash with water an...

Embodiment 2

[0068] Disperse 100 mg of microporous zirconium-based metal-organic framework (micro-UiO-66) in 1.6 mol / L propionic acid solution, let stand at 100°C for different times, wash with water and ethanol several times, and dry at 100°C for 24 hours to obtain different results. Hierarchical porous metal-organic framework nanomaterials with corrosion time.

[0069] Figure 5 It is the nitrogen adsorption-desorption curve and pore size distribution of each hierarchical porous metal organic framework nanomaterial obtained according to this embodiment. It can be seen that the 6-hour etching reaches equilibrium. The pore structure parameters of the samples with different etching times are given in Table 2 below, and it can be seen that the etching time of 6 hours is sufficient.

[0070] Table 2

[0071]

Embodiment 3

[0073] The implementation method and basic formula are the same as in Example 2, only the concentration of propionic acid is changed to 0.4, 0.8, 3.2, 4.8 and 5.6 mol / L to obtain hierarchical porous metal-organic framework nanomaterials with different propionic acid concentrations.

[0074] Figure 6 It is the nitrogen adsorption-desorption curve and pore size distribution diagram of each hierarchical porous metal organic framework nanomaterial obtained according to the present embodiment, Figure 7 It is a transmission electron micrograph of each hierarchical porous metal-organic framework nanomaterial obtained according to this embodiment. It can be found that the appearance of mesopores needs at least 0.8mol / L acid concentration, and the range of pores becomes larger with the increase of acid concentration. Table 3 below shows the pore structure parameters of etched samples with different acid concentrations. It can be seen that the concentration of monocarboxylic acid sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com