Zero-discharge treatment method for salt-containing coal-chemical wastewater

A technology of salt-containing wastewater and a treatment method is applied in the field of zero-discharge treatment of salt-containing wastewater and zero-discharge treatment of high-salt wastewater in coal chemical industry, which can solve the problems of inability to achieve zero discharge, ineffective integration of functions, and high cost, and achieve The effect of reducing processing cost, reducing processing difficulty, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

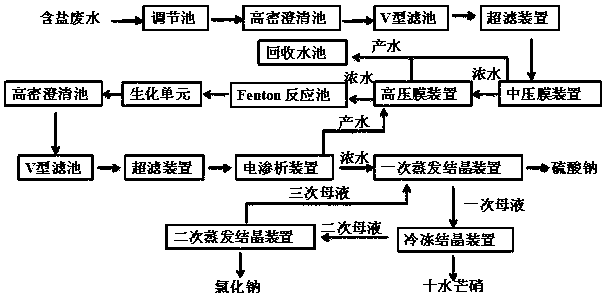

[0052] The average concentration of each pollutant in high-salt industrial wastewater is: COD is 80 mg / L, total hardness (as CaCO 3 Calculated) is 1500mg / L, total alkalinity (as CaCO 3 (calculated) is 800 mg / L, silicon dioxide is 30 mg / L, and TDS is 5000 mg / L, among which, the concentration of nitrate ion is 40 mg / L, the concentration of chloride ion is 700 mg / L, and the concentration of sulfate ion is 1000 mg / L. mg / L, pH value is 8. Such as figure 1 As shown, using the zero-discharge treatment process for coal chemical industry saline wastewater includes the following steps:

[0053] (1) The salty wastewater enters the high-density clarifier. According to the water quality of the saline wastewater, 1.8g / L calcium hydroxide is added to the reaction zone of the high-density clarifier to maintain the pH value at 10.5-11.0, and then add 2.0 g / L L sodium carbonate, then add 10 mg / L PFS for coagulation, 1mg / L PAM to aid coagulation, after fully coagulating in the reaction area, ...

Embodiment 2

[0063] Such as figure 1 As shown, utilizing the zero-discharge treatment process for coal chemical industry saline wastewater treatment process to treat the same wastewater as in Example 1 includes the following steps:

[0064] (1) The saline wastewater enters the high-density clarification tank. According to the water quality of the saline wastewater, 1.8g / L calcium hydroxide is added to the reaction zone of the high-density clarification tank to maintain the pH value at 11.0-11.5, and then add 2.5 g / L L sodium carbonate, then add 50 mg / L PFS for coagulation, 5mg / L PAM to aid coagulation, after fully coagulating in the reaction area, enter the clarification area of the high-density tank for sedimentation, and finally put it at the outlet of the high-density clarification tank Add hydrochloric acid or sulfuric acid to adjust the pH to about 7, and add non-oxidizing bactericide to prevent membrane fouling. After treatment, the hardness of the effluent from the high-density c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| turbidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com