In-situ growth and doping modification method for metal oxide nanometer catalyst

A nano-catalyst, in-situ growth technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc. problems such as force difference, to achieve the effect of controllable size and morphology, smooth and uniform surface, and strong bonding force of film base

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

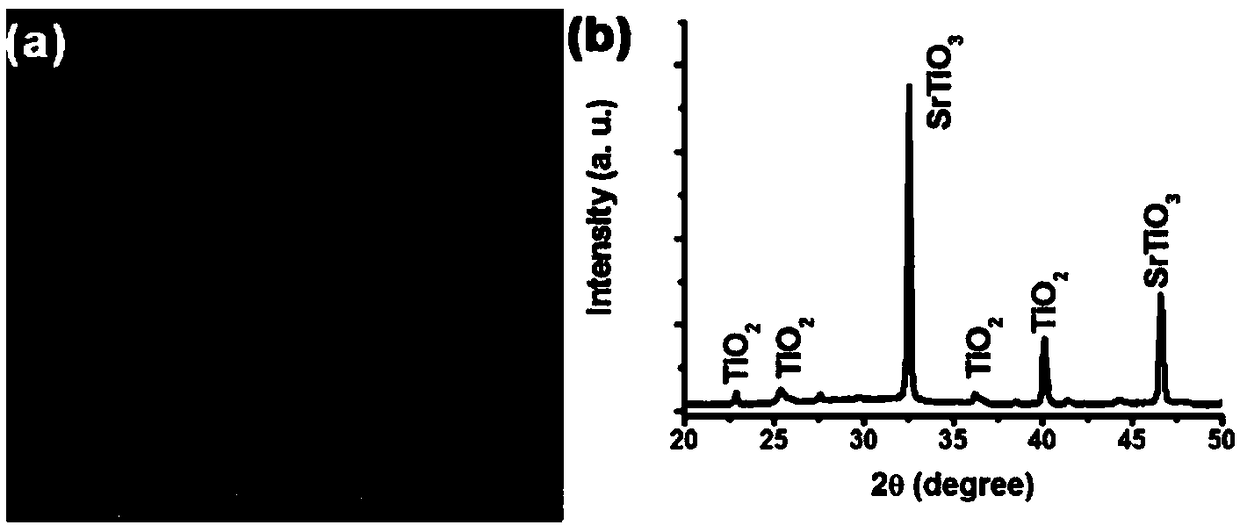

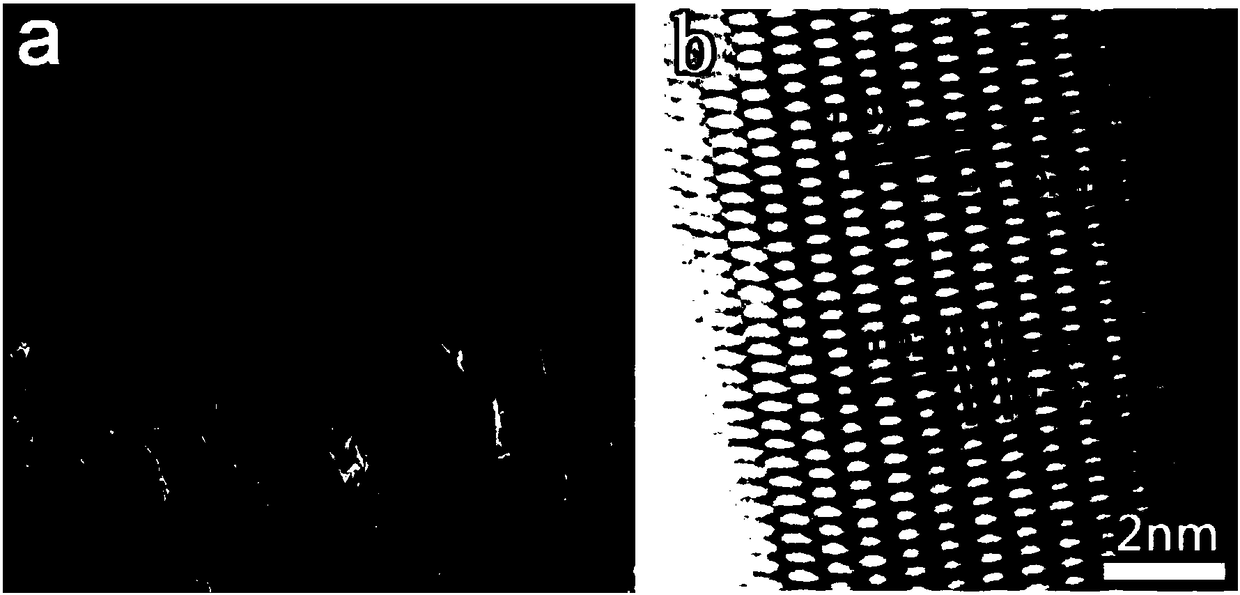

[0048] This example is SrTiO 3 The in-situ growth of nanoparticles on the surface of the Ti sheet metal substrate is as follows:

[0049] 1. Add 1L of deionized water to the beaker, and add 15.26g of Na 2 B 4 o 7 10H 2 O and 10.74g Sr(CH 3 COO) 2 1 / 2H 2 O, after mixing evenly, add 3.00g EDTA-2Na and 3.00g NaOH, and continue stirring for 1h to obtain the electrolyte solution for micro-arc oxidation.

[0050] 2. Using industrial pure titanium (Gr1) as the substrate, first cut the titanium sheet into a suitable size, and then pretreat it. Put the Ti sheet in acetone for 15 minutes to sonicate, remove the oil on the surface, then rinse the residual acetone with deionized water, and then put the Ti sheet in H at room temperature. 2 O:HNO 3: HF=5:4:1 (volume ratio) for 60s to remove the oxide layer on the surface, and finally wash it with deionized water and absolute ethanol.

[0051] 3. Put the electrolyte obtained in step 1 into a stainless steel electrolytic cell, then ...

Embodiment 2

[0057] This example is CeO 2 The in-situ growth of nanoparticles on the surface of Ti sheet and Ti mesh metal substrate is as follows:

[0058] 1. Add 1L deionized water to the beaker, and add 25.09g Na 3 PO 4 12H 2 O and 12.97 g Na 2 B 4 o 7 10H 2 O, add 15.86g Ce(CH 3 COO) 3 , continue stirring for 1h.

[0059] 2. Use industrial pure titanium as the substrate to pretreat it. place the base in H 2 O:HNO 3 :HF=5:4:1 (volume ratio) for 60s, then washed with deionized water and absolute ethanol.

[0060] 3. Put the electrolyte obtained in step 1 into an electrolytic cell, and use the pretreated industrially pure titanium as an anode electrode for micro-arc oxidation to perform micro-arc oxidation. Its current density is 10A / dm 2 , the time of micro-arc oxidation is 15min.

[0061] 4. Heat the sample obtained in step 3 at 950°C for 30 minutes, then air cool to room temperature to obtain CeO 2 nanoparticles.

[0062] CeO grown by the above method 2 The phase comp...

Embodiment 3

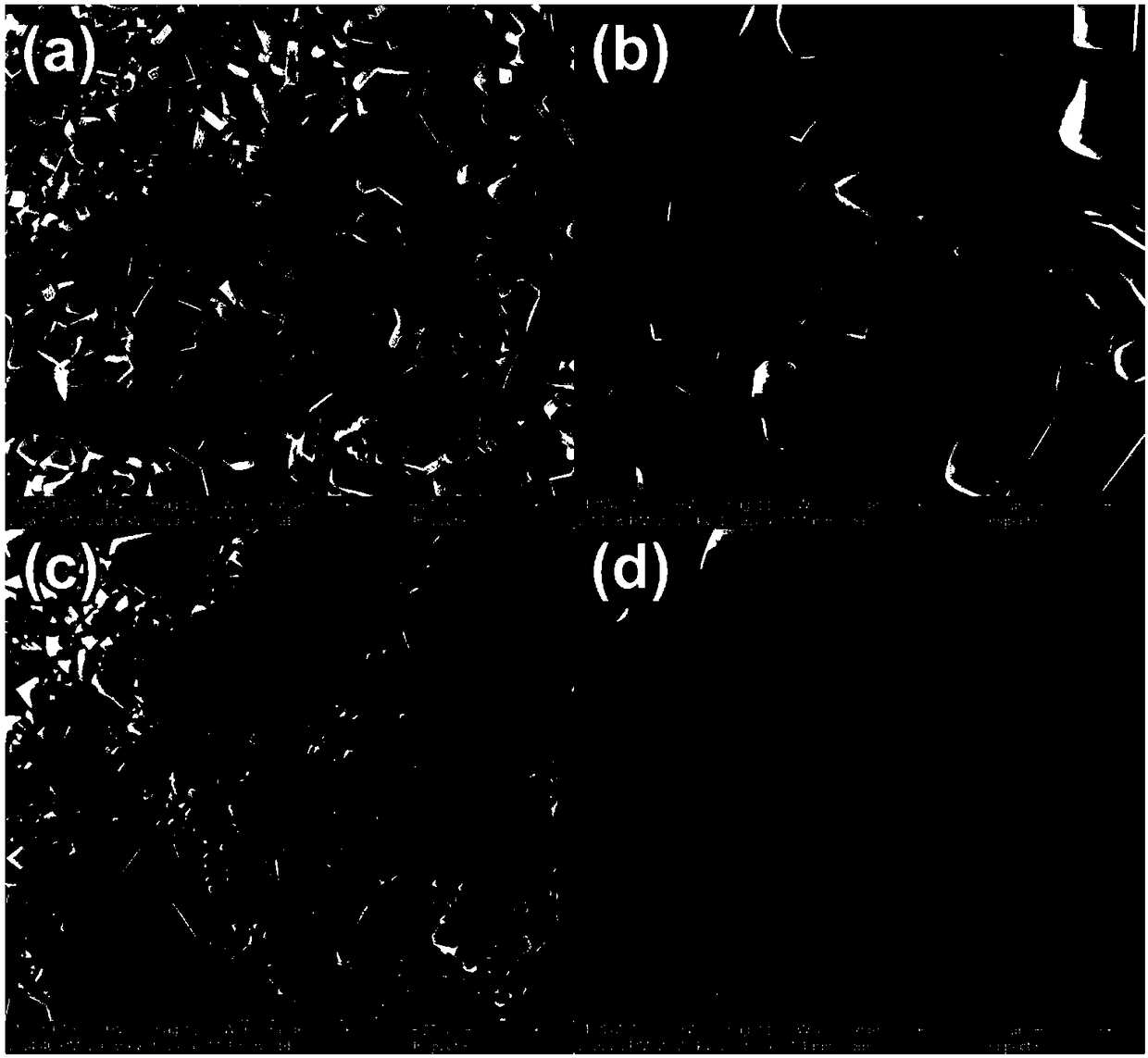

[0065] This embodiment is (Ni 1-x co x ) 5 TiO 7 The in-situ growth of nanowires on the surface of the Ti sheet metal substrate is as follows:

[0066] 1. Add 1L deionized water to the beaker, and add 38.14g Na 3 PO 4 12H 2 O and 12.97 g Na 2 B 4 o 7 10H 2 O, after mixing evenly, add 14~20g Ni(CH 3 COO) 2 2H 2 O and 1~10gCo(CH 3 COO) 2 2H 2 O, continue to stir for 30min.

[0067] 2. Use industrial pure titanium as the substrate to pretreat it. place the base in H 2 O:HNO 3 : HF=5:4:1 (volume ratio) for 60s, then washed 4 times with deionized water and 2 times with absolute ethanol.

[0068] 3. Put the electrolyte obtained in step 1 into an electrolytic cell, and use the pretreated industrially pure titanium as an anode electrode for micro-arc oxidation to perform micro-arc oxidation. Its current density is 10A / dm 2 , the time of micro-arc oxidation is 10min.

[0069] 4. Put the sample obtained in step 3 in a tube furnace and anneal at 850°C for 30 minutes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com