Solar driven device and method for treating wastewater and producing hydrogen by coupling

A technology for wastewater treatment and solar energy, applied in the field of solar-driven electrochemical systems, can solve the problems of high wastewater treatment cost, high impedance, high energy consumption, etc., and achieve the effects of increasing electrode surface area, shortening electrode spacing, and improving electrolysis efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

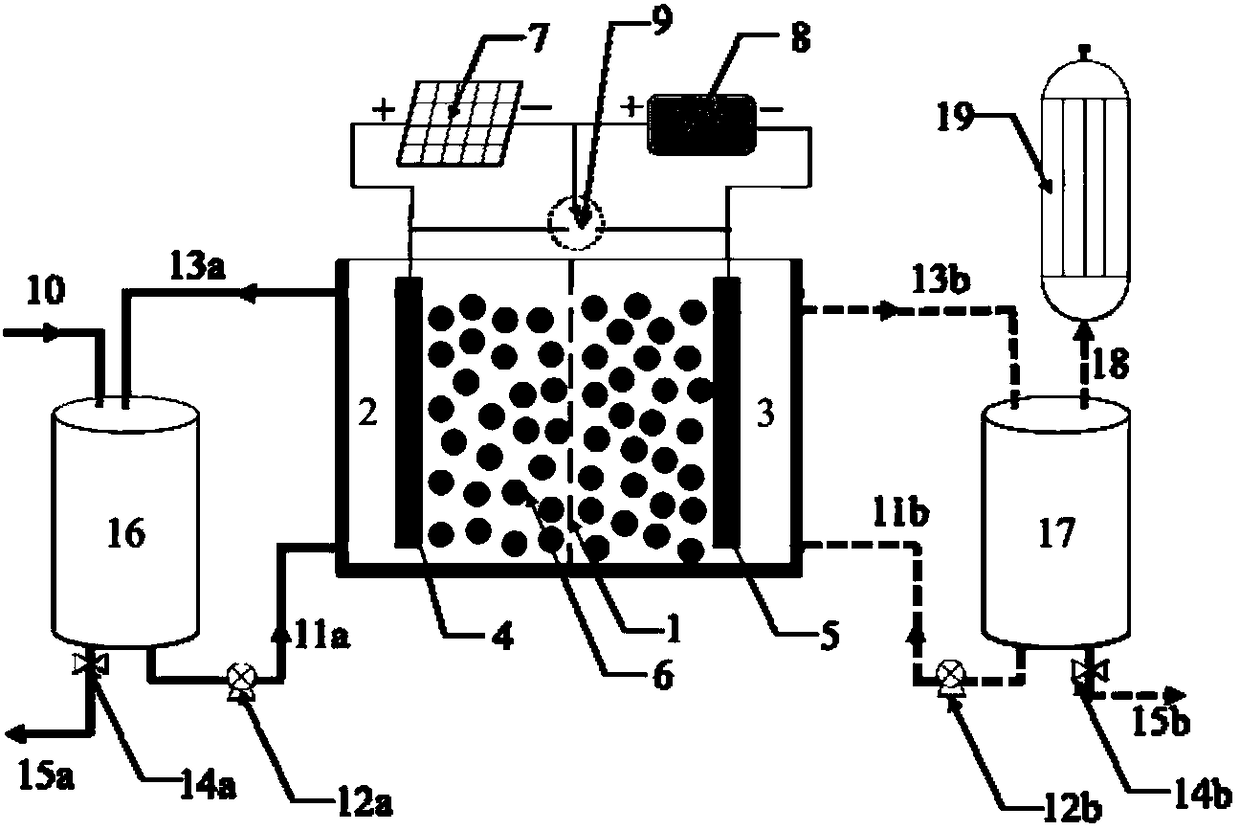

[0066] The experimental conditions are: the initial concentration of rhodamine B printing and dyeing wastewater is 100mg / L, the treated water volume is 3L, pH=7, 2g / L

[0067] Na 2 SO 4 Electrolyte, the wastewater is passed into the anode chamber of the three-dimensional catalytic electrode reactor, in which the particle electrode is saturated by the printing and dyeing wastewater and loaded with gamma MnO 2 Activated carbon particles, the particle size is 2-4mm, and the photovoltaic panel provides a current density of 100mA / cm 2 , the hydraulic retention time (HRT) is 10min, the treatment time is 3 hours, the lye in the cathode chamber is NaOH, and the concentration is 0.2g / L.

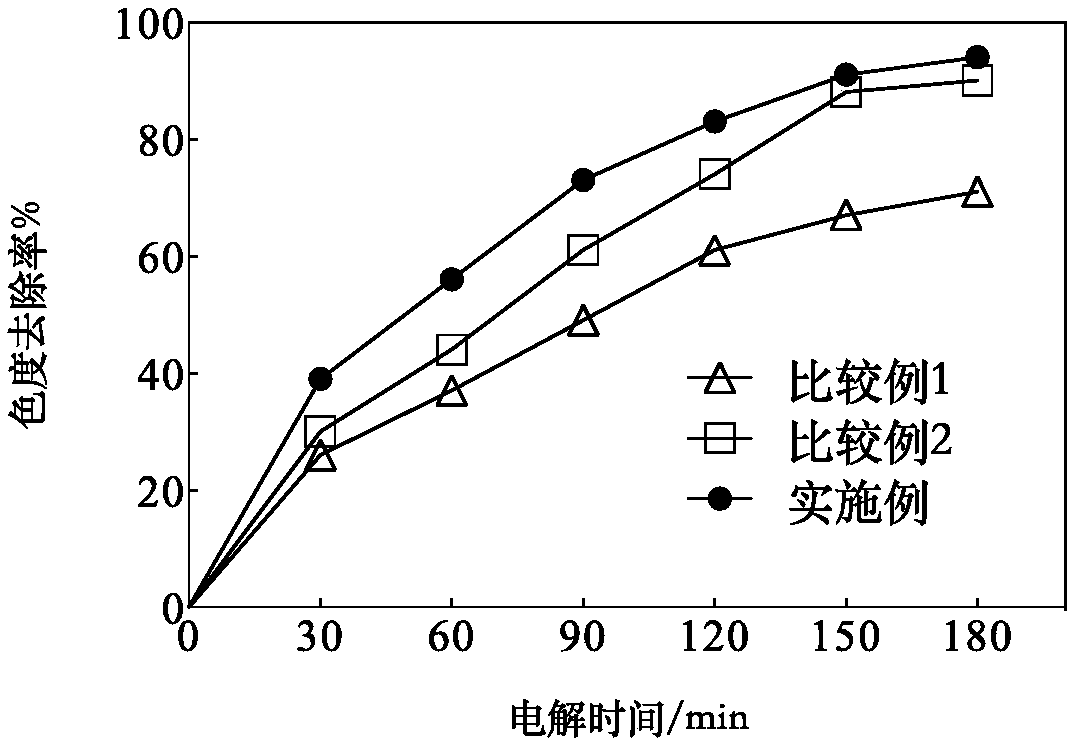

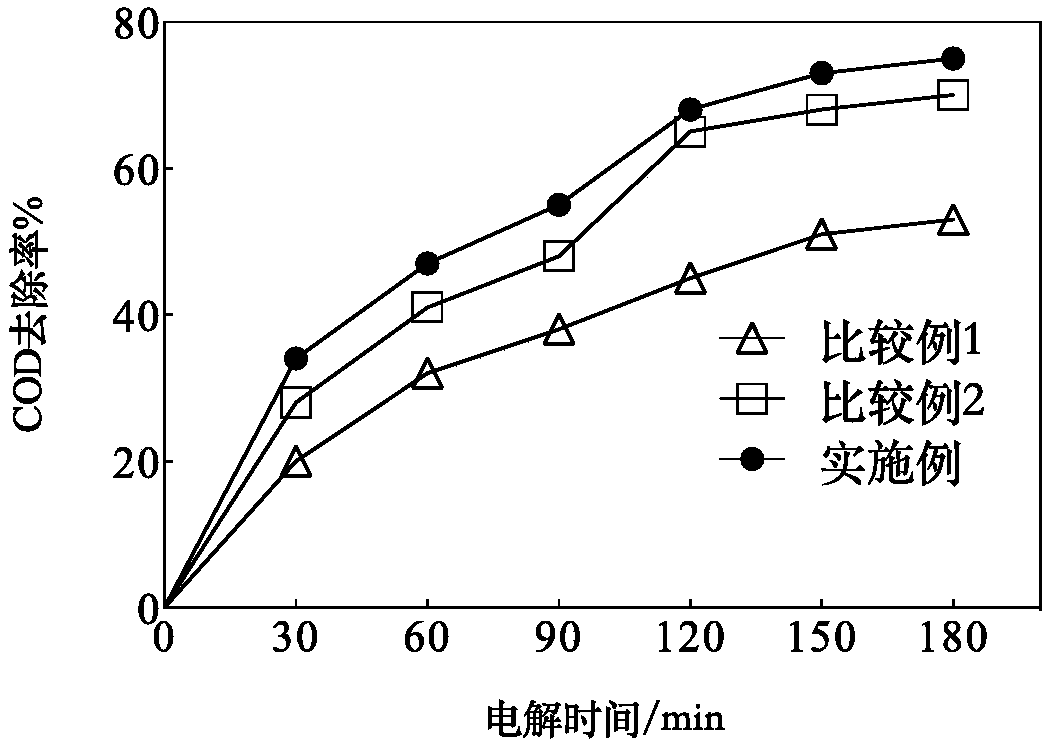

[0068] 2 (a), 2 (b) and 2 (c), it can be seen that a solar-driven wastewater treatment coupled hydrogen production device and method of the present invention, by filling the cathode and anode chambers with load gamma MnO 2 The activated carbon particle electrode improves the chromaticity of wastewa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com