Preparation method of polypyrrole/nickel hydroxide supercapacitor composite electrode material

A technology of supercapacitor and nickel hydroxide, which is used in the manufacture of hybrid capacitor electrodes and hybrid/electric double-layer capacitors, etc., can solve the problems of narrow chemical window and poor conductivity, and achieve low cost, high specific capacitance and wide source of raw materials. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] (1) Prepare an aqueous solution of nickel nitrate and pyrrole, the concentration of nickel ions is 0.2M, and the concentration of pyrrole monomer is 0.02M. Stir at room temperature for 2 h until the pyrrole monomer is completely dissolved to obtain an electrolyte.

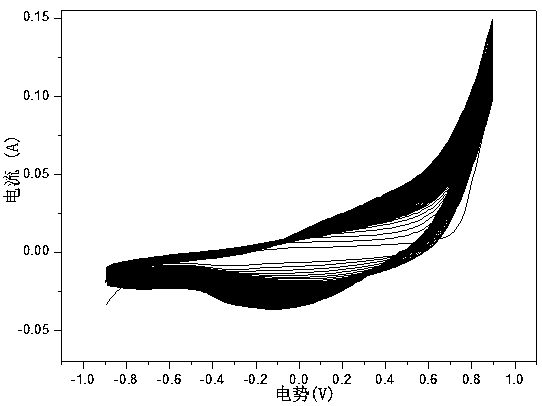

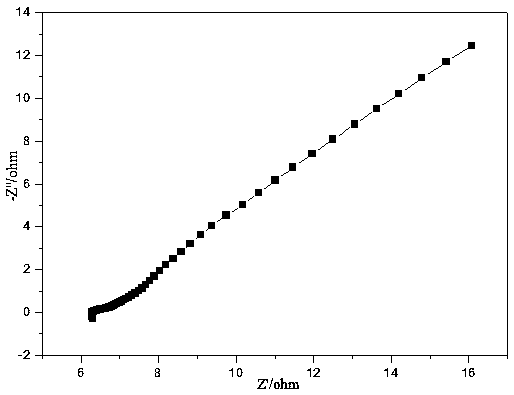

[0017] (2) Take 50mL of the electrolyte solution prepared in step (1) and put it into the electrolytic cell. 2 Compacted carbon paper was used as the working and counter electrodes. The saturated calomel electrode was used as the reference electrode, and a three-electrode system was configured, and the system was scanned by cyclic voltammetry for 150 cycles between -1V and 1V at a scan rate of 100mV / s.

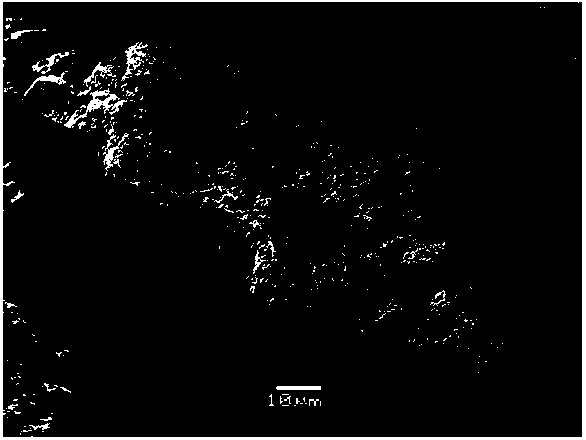

[0018] (3) After the reaction, remove the working electrode and counter electrode in step (2), soak in deionized water overnight to remove impurity ions, and dry at 60°C for 24 hours to obtain a polypyrrole / nickel hydroxide supercapacitor Composite electrode material.

Embodiment 2

[0020] Repeat the steps of Example 1, the concentration of nickel ions is 0.2M, and the concentration of pyrrole monomer is configured as 0.04M. (The ratio of the amount of pyrrole monomer to nickel ion is 0.2)

Embodiment 3

[0022] Repeat the steps of Example 1, the concentration of nickel ions is 0.2M, and the concentration of pyrrole monomer is configured as 0.05M. (The ratio of the amount of pyrrole monomer to nickel ion is 0.25)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com