Graphene carbon-coated sodium vanadium phosphate material, preparation method thereof and application method of sodium vanadium phosphate material used as sodium ion battery positive electrode material

A technology of carbon-coated sodium vanadium phosphate and sodium vanadium phosphate, which is applied in battery electrodes, circuits, electrical components, etc., can solve the problems of difficult control of high-temperature sintered structure, slow ion diffusion rate, poor electronic conductivity, etc., and achieve ion diffusion Short path, excellent electrochemical performance, and good crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

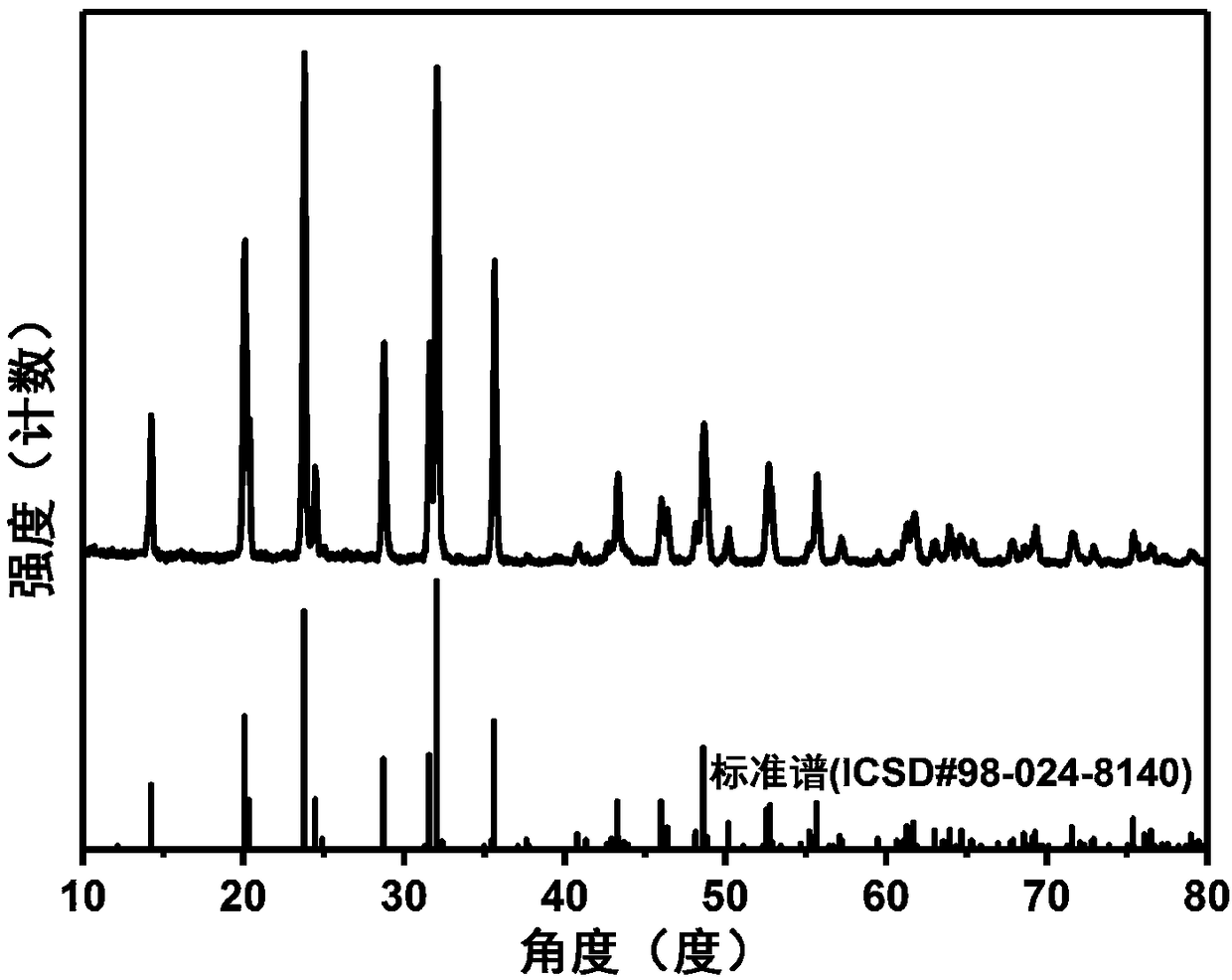

Embodiment 1

[0050] Add 2.0913g of ammonium dihydrogen phosphate and 5.188g of oleic acid into a 50ml stainless steel ball mill jar, add 20 304 stainless steel balls each with a diameter of 2mm and 4mm as the ball milling medium, and use a high-energy mechanical ball mill to mix for 3 hours to obtain milky white mixture. 10.376 g of paraffin wax was added, followed by ball milling for 2 hours. Then 2.184 g of vanadium oxalate was added, and ball milling was continued for 2 hours to obtain a viscous mixture. Finally, 1.566 g of anhydrous sodium acetate was added and ball milled for 3 hours to obtain a solid or semi-liquid sodium vanadium phosphate precursor. Turn the sodium vanadium phosphate precursor to a H 2 1Ar (Ar and H 2 In a quartz tube furnace with a volume ratio of 95:5) mixed gases, the heating rate was raised to 800°C for 8h at a heating rate of 2°C for 1min, and the furnace was cooled to obtain a graphene-like carbon-coated sodium vanadium phosphate material. The crystal str...

Embodiment 2

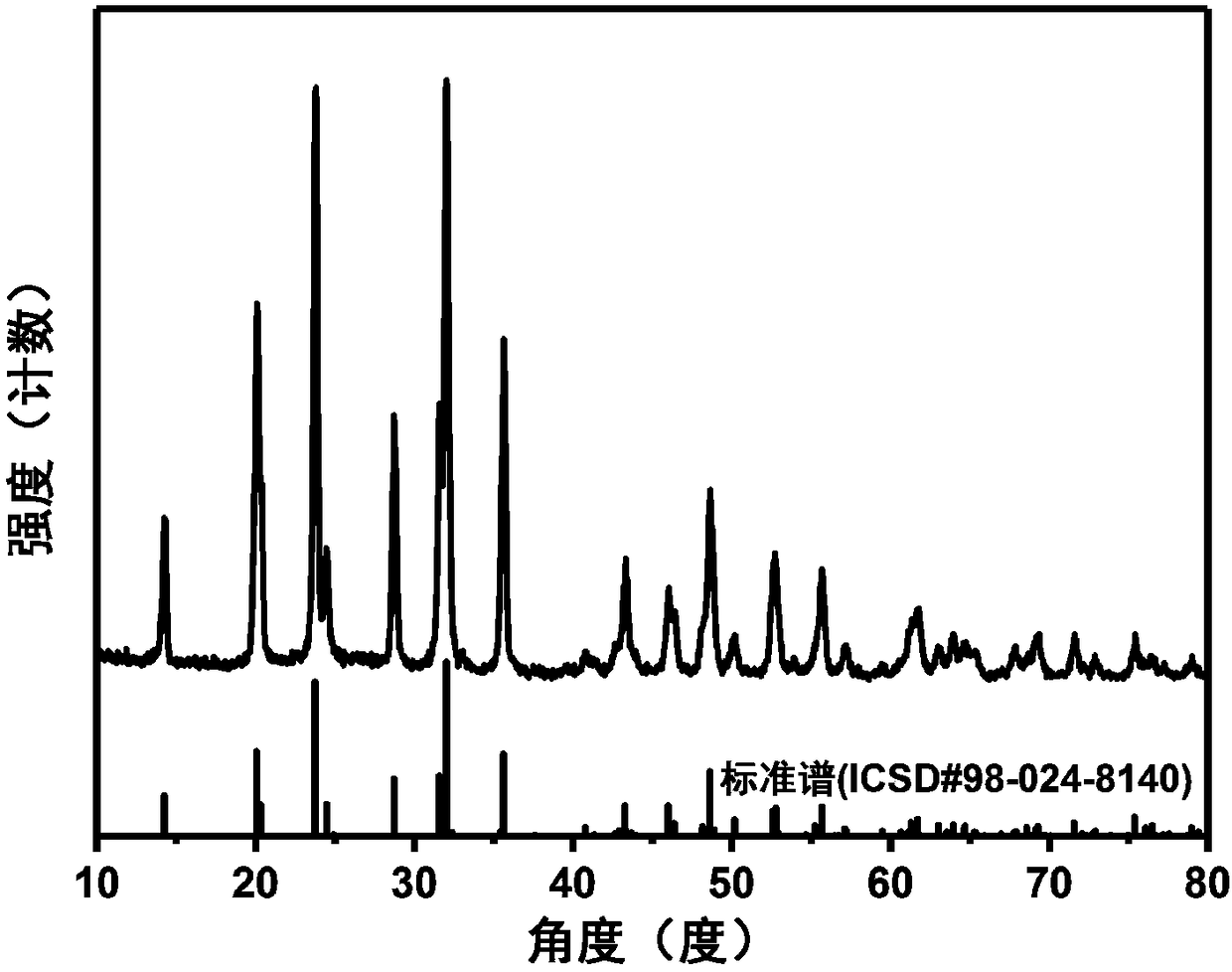

[0052] Add 2.0913g of ammonium dihydrogen phosphate and 7.782g of oleic acid into a 50ml stainless steel ball mill jar, add 20 304 stainless steel balls each with a diameter of 2 mm and 4 mm as the ball milling medium, and use a high-energy mechanical ball mill to mix for 3 hours to obtain milky white mixture. 10.376 g of paraffin wax was added, followed by ball milling for 2 hours. Then 2.184 g of vanadium oxalate was added, and ball milling was continued for 2 hours to obtain a viscous mixture. Finally, 1.566 g of anhydrous sodium acetate was added and ball milled for 3 hours to obtain a solid or semi-liquid sodium vanadium phosphate precursor. Turn the sodium vanadium phosphate precursor to a H 2 1Ar (Ar and H 2 In a quartz tube furnace with a volume ratio of 95:5) mixed gases, the heating rate was raised to 800°C for 8h at a heating rate of 2°C for 1min, and the furnace was cooled to obtain a graphene-like carbon-coated sodium vanadium phosphate material.

Embodiment 3

[0054] Add 3.4855g of ammonium dihydrogen phosphate and 8.559g of oleic acid into a 50ml stainless steel ball mill jar, add 20 304 stainless steel balls each with a diameter of 2mm and 4mm as the ball milling medium, and use a high-energy mechanical ball mill to mix for 3 hours to obtain milky white mixture. 17.118 g of paraffin wax was added, followed by ball milling for 2 hours. Then 3.64 g of vanadium oxalate was added, and ball milling was continued for 2 hours to obtain a viscous mixture. Finally, 2.61 g of anhydrous sodium acetate was added and ball milled for 3 hours to obtain a solid or semi-liquid sodium vanadium phosphate precursor. Turn the sodium vanadium phosphate precursor to a H 2 1Ar (Ar and H 2 In a quartz tube furnace with a volume ratio of 95:5) mixed gases, the heating rate was raised to 800°C for 8h at a heating rate of 2°C for 1min, and the furnace was cooled to obtain a graphene-like carbon-coated sodium vanadium phosphate material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com