Applications of D-isoascorbic acid and/or salt thereof in coating materials, and anti-oxidation coating material and preparation method thereof

A technology of isoascorbic acid and anti-oxidation paint, applied in the field of paint, can solve the problems of paint surface oxidation, peeling, cracking, etc., and achieve the effects of low cost, safe use and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

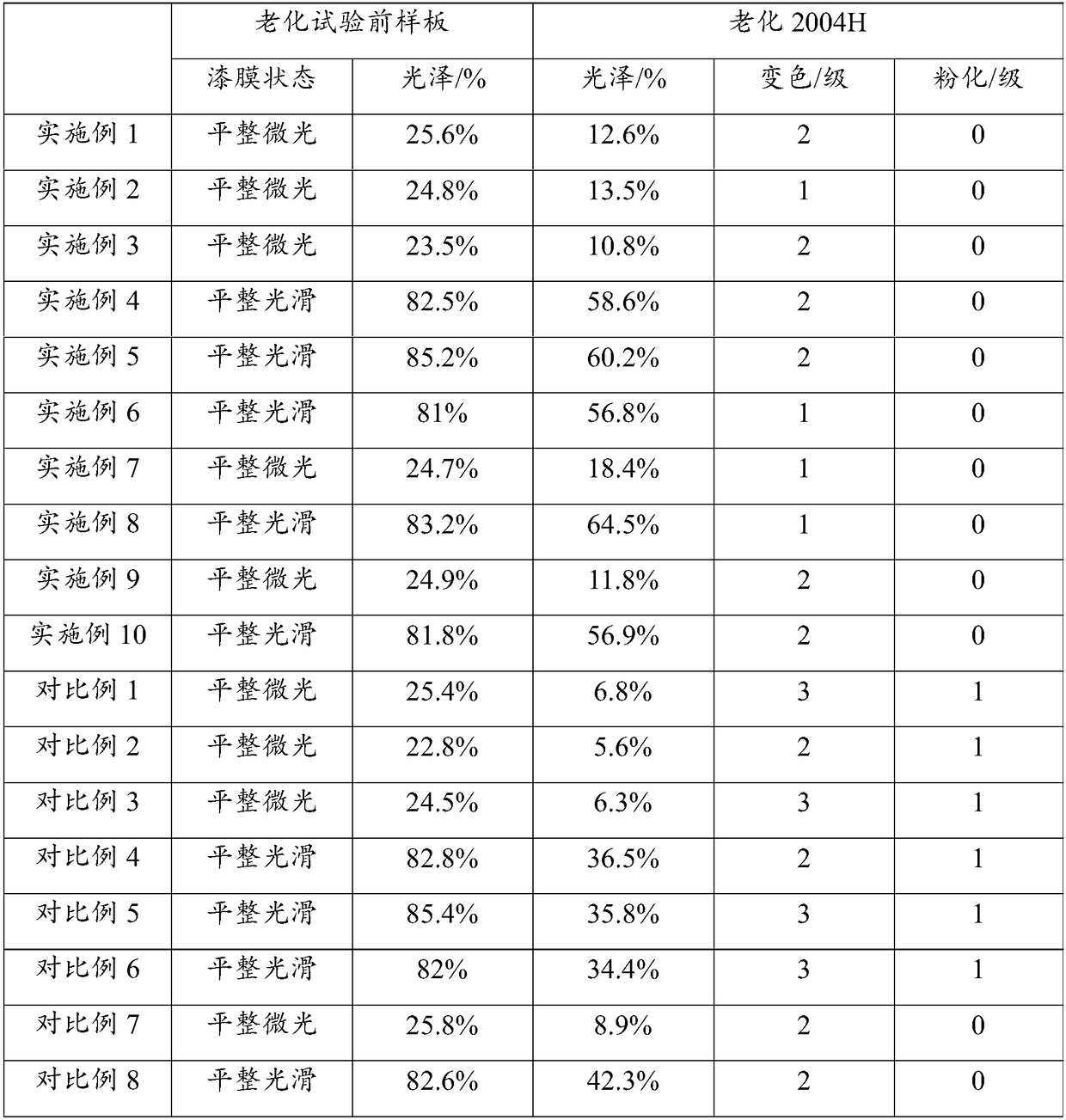

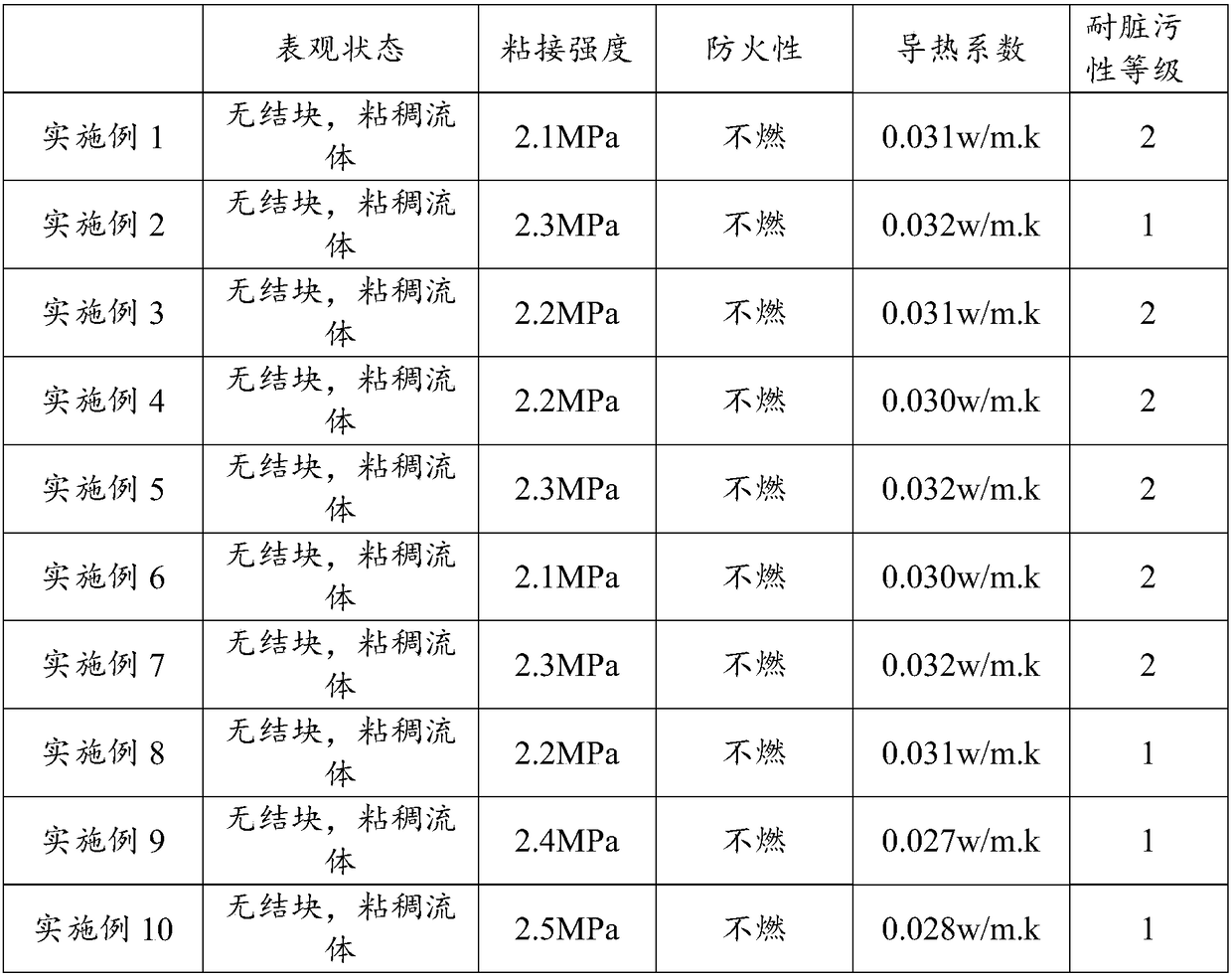

Examples

preparation example Construction

[0109] According to a third aspect of the present invention, a method for preparing the above-mentioned anti-oxidation coating is provided, comprising the following steps:

[0110] The antioxidant is uniformly mixed with other raw materials in the paint to obtain the antioxidant paint.

[0111] The coating can be prepared according to conventional techniques in the art, and then the antioxidant containing D-isoascorbic acid and / or its salt is added to the coating and mixed evenly. The preparation process is simple to operate and has no adverse effect on the stability of the paint product.

Embodiment 1

[0114] An anti-oxidation interior wall engineering paint, which is composed of the following components: solvent water 30%, antifreeze agent ethylene glycol 0.5%, dispersant AR-1 0.5%, wetting agent SF-1 0.1%, multifunctional additive Codis-99 0.1%, defoamer T-503 0.1%, antioxidant D-sodium erythorbate 0.5%, preservative K55 0.1%, pigment anatase titanium white 3%, filler kaolin 6%, filler heavy calcium (800 mesh ) 20%, filler light calcium (1000 mesh) 10%, filler talc powder (1250 mesh) 8%, film-forming aid alcohol ester-120.5%, defoamer T-503 0.1%, styrene-acrylic emulsion GC-6590 20 %, thickener MS-2 (1:1 water) 0.5%.

Embodiment 2

[0116] An anti-oxidation interior wall engineering paint, composed of the following components: solvent water 20%, antifreeze agent ethylene glycol 0.5%, dispersant AR-1 0.5%, wetting agent 104PG50 0.1%, multifunctional additive Codis- 99 0.1%, defoamer Tween 0.1%, antioxidant D-sodium erythorbate 0.5%, preservative K55 0.1%, pigment cobalt blue 3%, filler kaolin 6%, filler heavy calcium (800 mesh) 20%, filler Light calcium (1000 mesh) 10%, filler talc powder (1250 mesh) 8%, film-forming aid ethylene glycol monobutyl ether 0.5%, defoamer T-503 0.1%, styrene-butadiene emulsion L-8242 30%, Thickener MS-2 (1:1 water) 0.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com