Lithium ion battery composite negative material and preparation method thereof

A lithium-ion battery and negative electrode material technology, applied in battery electrodes, negative electrodes, secondary batteries, etc., can solve the problems of active materials such as loss of effective electrical contact, loss of electrochemical activity, high surface activity, etc., to improve high temperature stability and Chemical stability, improvement of electrochemical performance, effect of alleviating volume expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

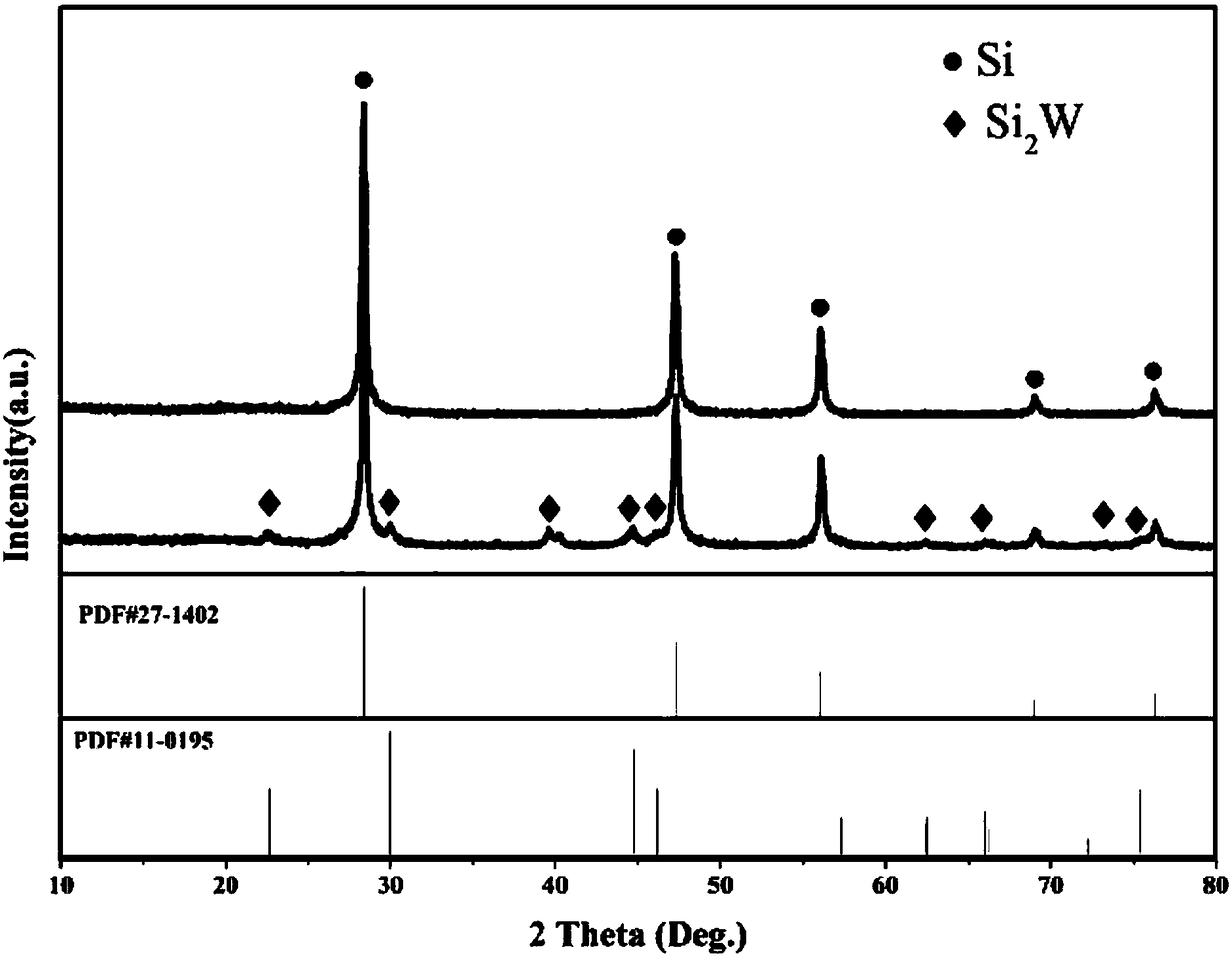

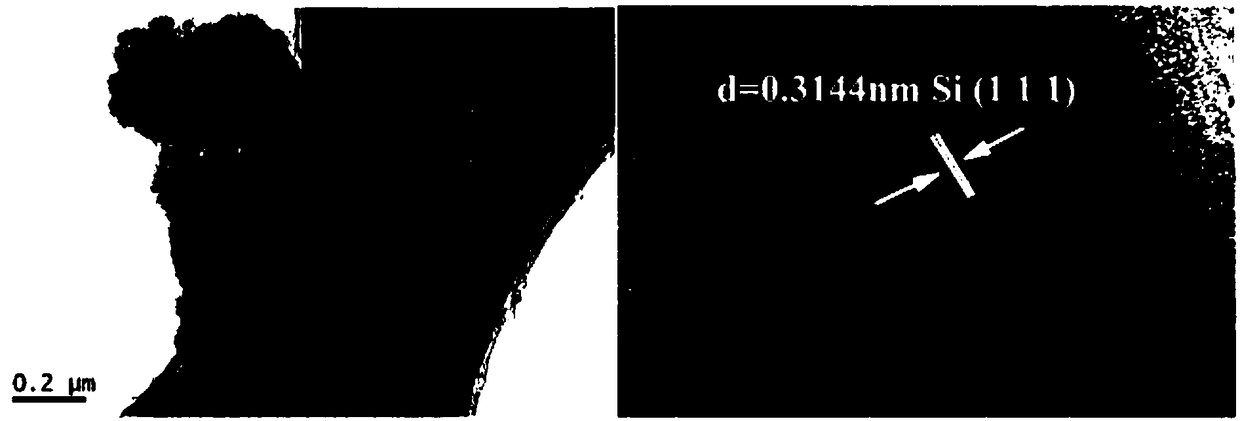

[0038] This embodiment provides a lithium-ion battery composite negative electrode material, which includes silicon oxide and a soluble salt of a refractory metal dissolved in a medium solution; the mixture of the two makes the surface of the silicon oxide covered by the refractory Soluble salt coating of the metal, silicon-silicon alloy negative electrode material coated with silicon alloy obtained after high-temperature heat treatment; wherein, in the silicon oxide and the soluble salt of the refractory metal, the molar ratio of silicon is 0.05~0.5 .

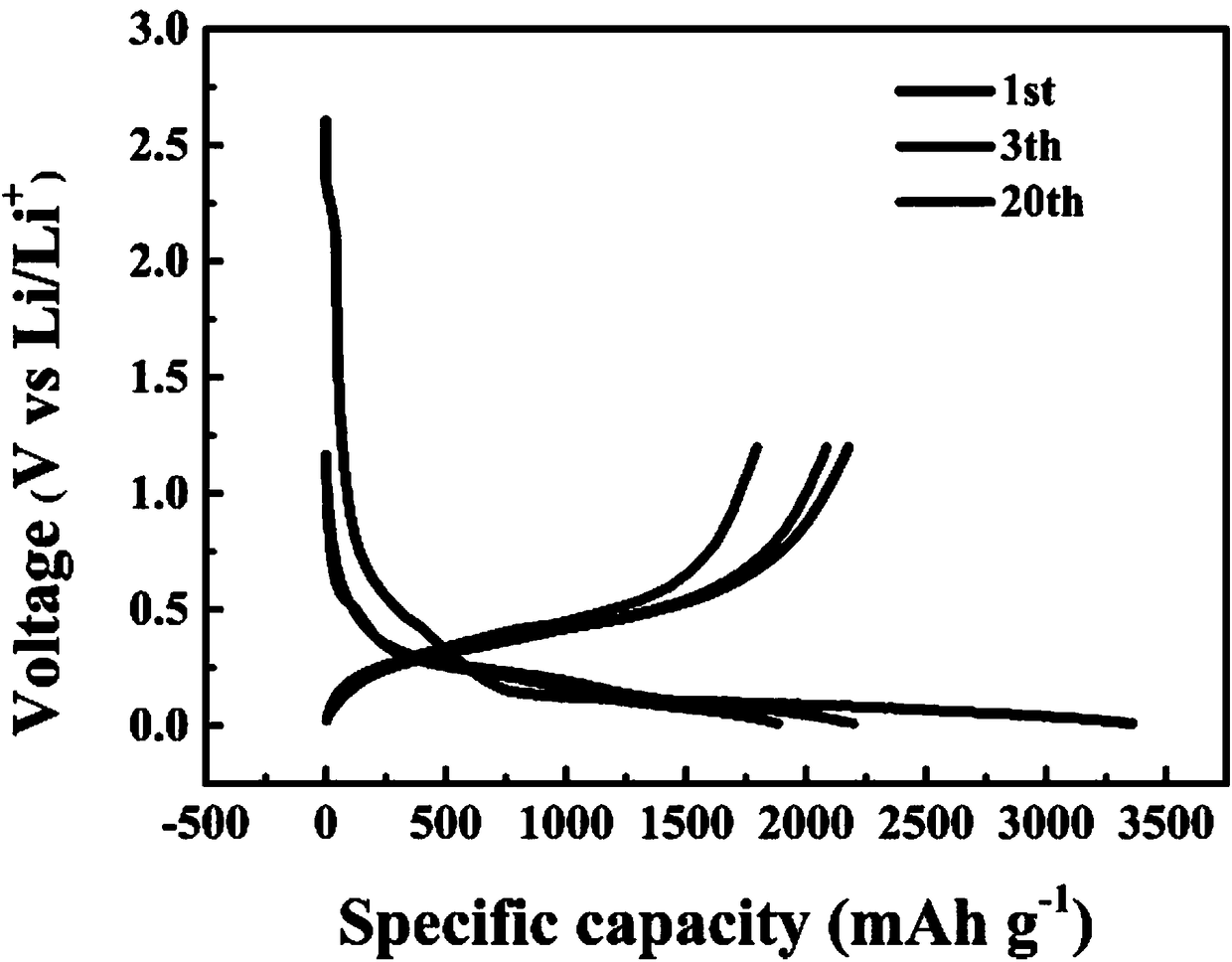

[0039]In this example, the in-situ chemical reaction is used to coat the silicon surface with silicon alloy. Due to its good adhesion, the synthesized silicon alloy coating can effectively adhere to the surface of the silicon material, thereby effectively relieving the silicon The volume expansion of the material during charge and discharge; at the same time, the silicon alloy can improve the conductivity of silicon, enhance t...

Embodiment 2

[0045] On the basis of Example 1, as a changeable example, this example further provides a composite negative electrode material for a lithium-ion battery, which includes silicon oxide and refractory metal oxide / sulfide dispersed in a medium solution The two are mixed so that the surface of the silicon oxide is covered by the refractory metal oxide / sulfide, and a silicon-silicon alloy negative electrode material coated with a silicon alloy is obtained after high-temperature heat treatment; wherein, in the silicon oxide The molar ratio of silicon to the refractory metal oxide / sulfide is 0.05-0.5.

[0046] In this example, the in-situ chemical reaction is used to coat the silicon surface with silicon alloy. Due to its good adhesion, the synthesized silicon alloy coating can effectively adhere to the surface of the silicon material, thereby effectively relieving the silicon The volume expansion of the material during charge and discharge; at the same time, the silicon alloy can i...

Embodiment 3

[0051] On the basis of Example 1, this example further provides a method for preparing a lithium-ion battery composite negative electrode material, which includes the following steps:

[0052] Step 1, dissolving the soluble salt of the refractory metal in the medium solution; or dispersing the refractory metal oxide / sulfide in the medium solution;

[0053] Step 2, adding silicon oxide to the mixed solution obtained in step 1, and drying after ultrasonic dispersion; wherein, in the soluble salt of the silicon oxide and the refractory metal, or in the silicon oxide and the In the refractory metal oxide / sulfide, the molar ratio of silicon is 0.05 ~ 0.5;

[0054] Step 3. If the soluble salt of refractory metal is used in step 1, the product of step 2 is calcined, and then magnesium powder and sodium chloride are added for mixing to obtain the precursor; if in step 1 If refractory metal oxides / sulfides are used, the result of step 2 is directly mixed with magnesium powder and sodi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Charging capacity | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

| Charging capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com