Ore tailing hydraulicity road material and preparation method thereof

A technology for road materials and ore tailings, applied in the directions of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of colloids failing to form a unified whole, destroying soil structure and connection, and easy cracking of road bases. Achieve the effect of increased strength, high chemical stability, and high resistance to water erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

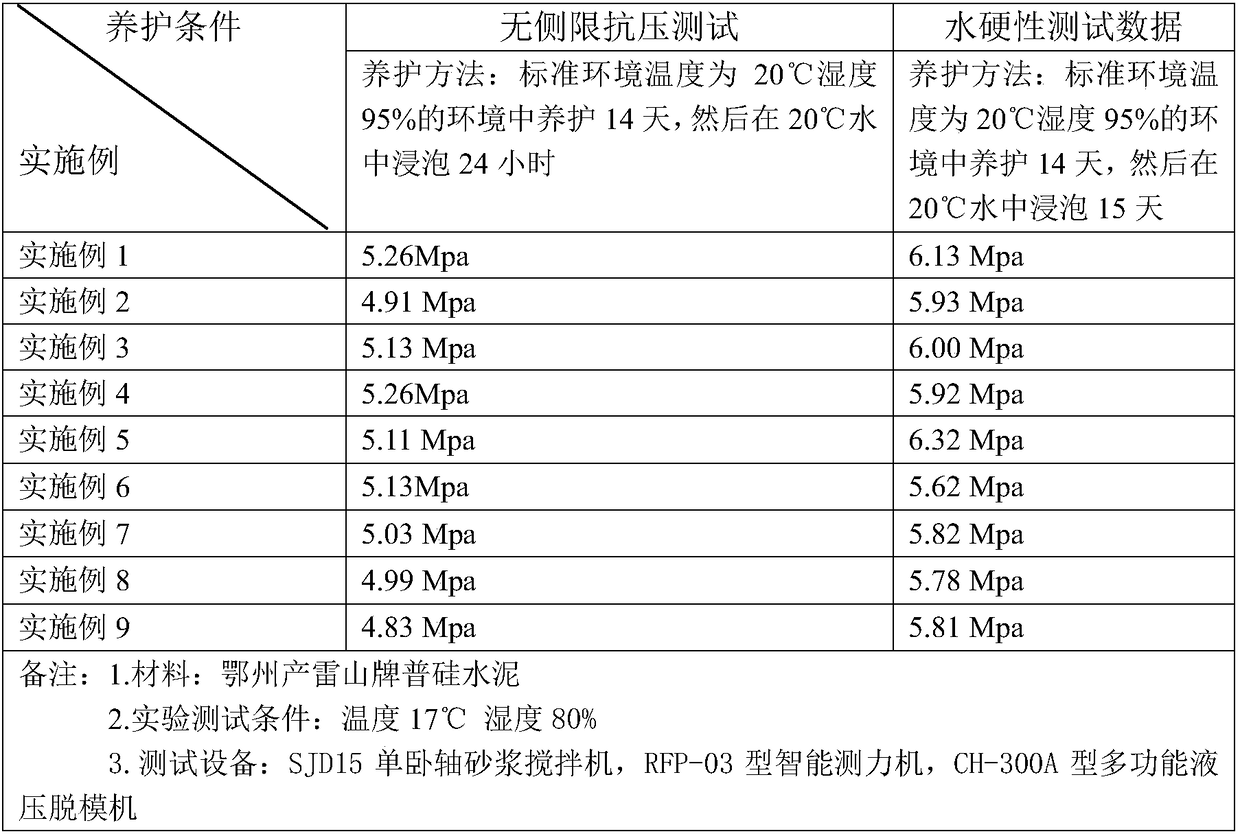

Examples

Embodiment 1

[0044] Embodiment one: a kind of ore tailings hydraulic road material, described road material is made of the raw material of following percentage by weight: gold ore tailings 91%, cement 8.5%, curing agent 0.5%, described curing agent is made of the following substances Aqueous solution configured according to mass fraction:

[0045] Cationic Chelate 3%

[0046] Nano Zirconia 0.02%

[0047] Nano cerium oxide 0.01%

[0048] Ethylenediamine 0.03%

[0049] n-Butyraldehyde 0.1%

[0053] Naphthalenesulfonic acid formaldehyde condensate 2%

[0054] Polyvinyl alcohol 0.8%

[0055] Dimethylaniline 2%

[0057] Sodium Alkylbenzene Sulfonate 0.5%

[0058] The balance is water,

[0059] Wherein, the cationic chelate is a metal ion chelate formed by chelating magnesium ions with ethylenediaminetetraacetic acid (EDTA).

Embodiment 2

[0060] Embodiment two: a kind of ore tailings hydraulic road material, described road material is made of the raw material of following percentage by weight: lead-zinc ore tailings 90%, fly ash 4%, cement 5.8%, curing agent 0.2%, The curing agent is an aqueous solution configured by the following substances according to the mass fraction:

[0061] Cationic Chelate 3%

[0062] Nano Zirconia 0.035%

[0063] Ethylenediamine 0.2%

[0066] Naphthalenesulfonic acid formaldehyde condensate 3%

[0068] Sodium Alkylbenzene Sulfonate 1%

[0069] The balance is water,

[0070] Wherein, the cationic chelate is a metal ion chelate formed by chelating magnesium ions and diethylenetriaminepentaacetic acid.

Embodiment 3

[0071] Embodiment three: a kind of ore tailings hydraulic road material, described road material is made of the raw material of following percentage by weight: iron ore tailings 89%, anhydrite 4%, cement 6.6%, curing agent 0.4%, described The curing agent is an aqueous solution composed of the following substances according to the mass fraction:

[0072] Cationic Chelate 2.5%

[0073] Nano Zirconia 0.01%

[0074] Nano cobalt oxide 0.01%

[0075] Ethylenediamine 0.05%

[0076] Paraformaldehyde 0.07%

[0078] Manganese Sulfate 2%

[0079] Chromium Sulfate 3%

[0080] Vinyl acetate 1%

[0081] Methyltetrahydrophthalic anhydride 1%

[0082] Sodium Phosphate 1%

[0083] Sodium Alkylbenzene Sulfonate 1%

[0084] The balance is water,

[0085] Wherein, the cationic chelate is a metal ion chelate formed by chelating calcium ions and ethylenediaminetetraacetic acid (EDTA).

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com