Preparation method of separator for sodium ion battery

A sodium-ion battery and diaphragm technology, applied in secondary batteries, battery components, circuits, etc., can solve the problems of large electrolyte liquid volume, low strength, and increased internal resistance of the battery system, and achieve simple production processes Easy to control, high heat resistance and stability, uniform pore distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

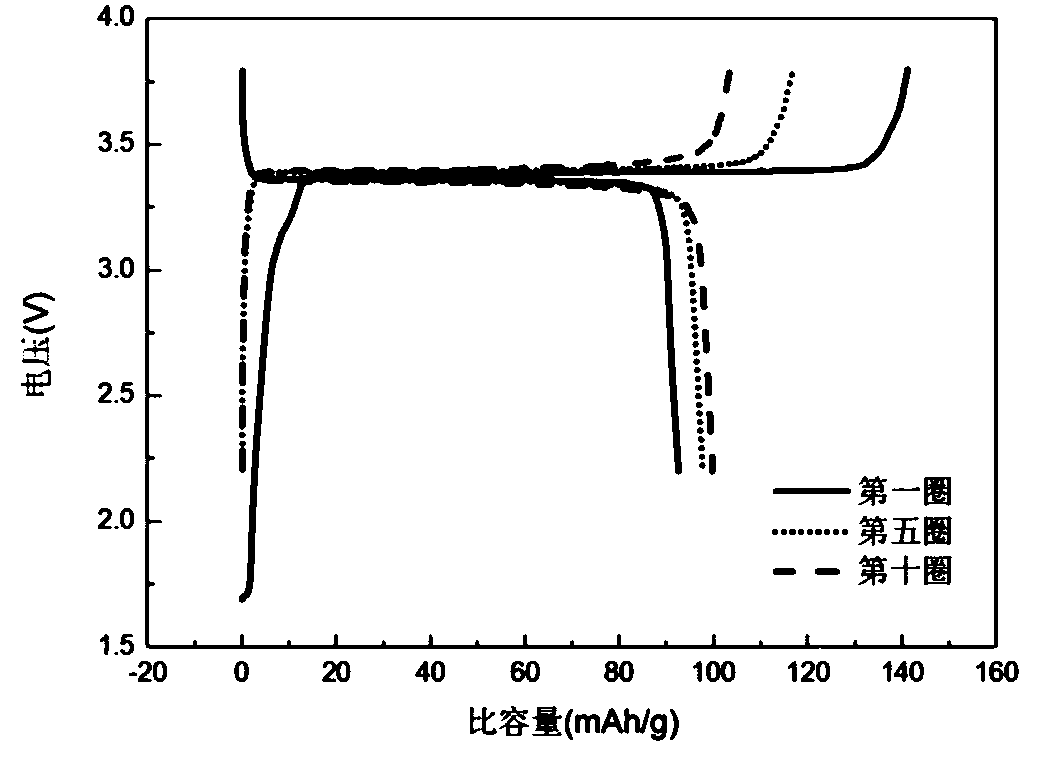

Image

Examples

Embodiment 1

[0024] A preparation method for a diaphragm for a sodium ion battery, comprising the steps of:

[0025] S1, respectively measure 9.7ml of N-methylformamide and 300μl of glycerin, mix and stir in the sample bottle for 1h to obtain a (DMF-glycerol) homogeneous solution, set aside;

[0026] S2. Weigh 5g of polyvinylidene fluoride powder into a round bottom flask, add 4ml of prepared (DMF-glycerol) solution, and stir at 550r / min magnetic force for 5h at a constant temperature of 20°C to obtain a uniformly dissolved gel slurry;

[0027] S3. After the gel slurry obtained in step S2 is left to stand for a while, the air bubbles therein are completely removed;

[0028] S4. Use a pipette to absorb 2ml of the clear gel paste obtained in step S3 and drop it onto a smooth glass plate, and spread it evenly with a 200 μm spatula to form a film;

[0029] S5. Cover the slurry-coated substrate obtained in step S4 with a petri dish, let it stand for a while, put it in a vacuum oven, dry it in ...

Embodiment 2

[0031] A preparation method for a diaphragm for a sodium ion battery, comprising the steps of:

[0032] S1, respectively measure 9.7ml of acetone and 300 μl of glycerin, mix and stir in the sample bottle for 1 hour to obtain a homogeneous solution of (acetone-glycerol), set aside;

[0033] S2. Weigh 5g of polyvinylidene fluoride powder into a round bottom flask, then add 4ml of the prepared (acetone-glycerin) solution, and stir at 550r / min magnetic force for 5h at a constant temperature of 20°C to obtain a uniformly dissolved gel slurry;

[0034] S3. After the gel slurry obtained in step S2 is left to stand for a while, the air bubbles therein are completely removed;

[0035] S4. Use a pipette to absorb 2ml of the clear gel paste obtained in step S3 and drop it onto a smooth glass plate, and spread it evenly with a 200 μm spatula to form a film;

[0036] S5. Cover the slurry-coated substrate obtained in step S4 with a petri dish, let it stand for a while, put it in a vacuum o...

Embodiment 3

[0038] A preparation method for a diaphragm for a sodium ion battery, comprising the steps of:

[0039] S1, respectively measure 8.5ml of N-methylformamide and 1.5ml of deionized water, mix and stir in the sample bottle for 1h to obtain a (DMF-deionized water) uniform solution, set aside;

[0040] S2. Weigh 5g of polyvinylidene fluoride powder into a round bottom flask, then add 6ml of the prepared (DMF-deionized water) solution, and stir at 550r / min magnetic force for 5h at a constant temperature of 80°C to obtain a uniformly dissolved gel pulp;

[0041] S3. After the gel slurry obtained in step S2 is left to stand for a while, the air bubbles therein are completely removed;

[0042] S4. Use a pipette to absorb 2ml of the clear gel paste obtained in step S3 and drop it onto a smooth glass plate, and spread it evenly with a 200 μm spatula to form a film;

[0043] S5. After covering the substrate coated with the slurry obtained in step S4 with a petri dish, let it stand for a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com