Preparation of extreme pressure antiwear agent and application of extreme pressure antiwear agent to new energy resource electric automobile gearbox oil

An extreme pressure anti-wear agent, pyridine technology, applied in the field of lubricating oil, can solve the problems of high acid value of oil, wear of parts, high dosage, and achieve the effect of low dosage, low oil loss and low friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

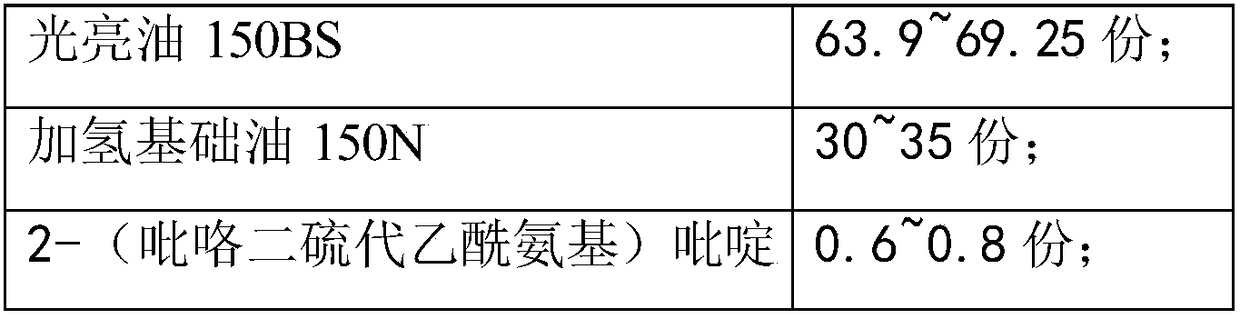

Method used

Image

Examples

Embodiment 1

[0024] Synthesis of 2-(pyrrole dithioacetamido) pyridine as a low acid value extreme pressure antiwear agent:

[0025] Under the environment of nitrogen stream protection, the massfraction that takes 67.09g is that the pyrrole acetone solution of 20% is transferred in the there-necked flask of 500ml, the sodium hydroxide solid powder that adds 40ml carbon disulfide and 8.0g successively is evenly dispersed in the flask, in Rapid magnetic stirring in an ice bath at -10°C-8°C for 10 to 15 hours, use a water separator to separate the upper water layer, filter to obtain the crude product, crystallize with absolute ethanol, and dry in vacuum to obtain colorless flaky crystals and Sodium pyrrole dithioformate.

[0026] Under the protection of nitrogen flow, add 0.2mol 2-aminopyridine, 100mL chloroform and 0.3mol anhydrous pyridine to a 500mL three-neck flask, add 0.24mol chloroacetyl chloride dropwise at normal temperature and pressure, and stir for 4h. The solvent was evaporated, ...

Embodiment 2

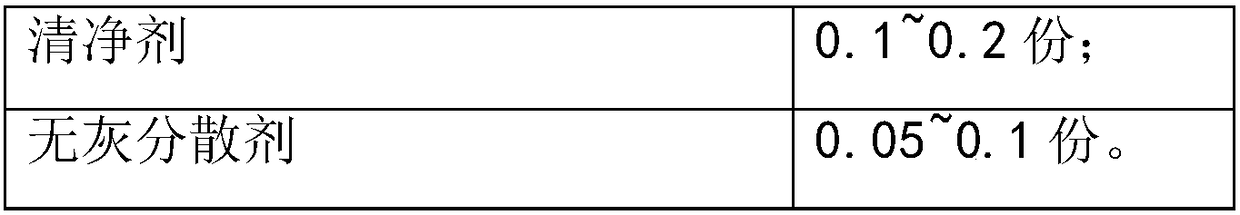

[0029] A low-acid value extreme pressure antiwear agent of the present invention and sulfur nitrogen heterocyclic compound 2-(pyrrole dithioacetylamino)pyridine extreme pressure antiwear performance and traditional extreme pressure antiwear agent sulfurized isobutylene T321 and dialkyl Comparison of anti-wear properties of zinc dithiophosphate T203:

[0030] SH / T 0189 test method, 392N pressure, 1200r / min, room temperature, 60min to test the wear scar diameter.

[0031]

[0032] Data analysis shows that: a kind of extreme pressure antiwear agent with low acid value of the present invention and sulfur nitrogen heterocyclic compound 2-(pyrrole dithioacetamido)pyridine extreme pressure antiwear performance and traditional extreme pressure antiwear additive T321 and T203 The comparative anti-wear performance is still excellent.

Embodiment 3

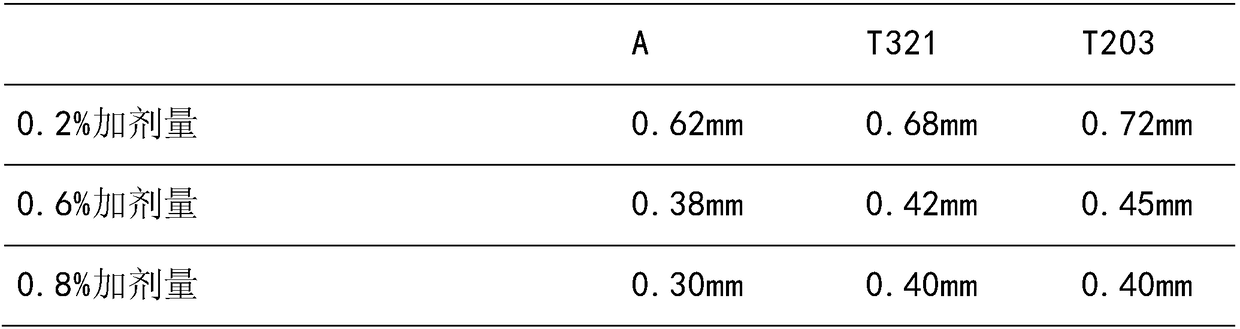

[0034] A low-acid value extreme pressure antiwear agent of the present invention and sulfur nitrogen heterocyclic compound 2-(pyrrole dithioacetylamino)pyridine extreme pressure antiwear performance and traditional extreme pressure antiwear agent sulfurized isobutylene T321 and dialkyl Comparison of corrosion performance of zinc dithiophosphate T203 copper sheet:

[0035] GB / T 5096 test method, 121°C, 60min, compare the corrosion level of copper sheet.

[0036]

[0037] Data analysis shows: a kind of low acid value extreme pressure anti-wear agent of the present invention and sulfur nitrogen heterocyclic compound 2-(pyrrole dithioacetamido) pyridine copper sheet corrosion performance and additive T321 and T203 compare copper sheet corrosion resistance better.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com