Method of preparing nano porous cobalt selenide in low-eutectic ionic liquid via electrodeposition

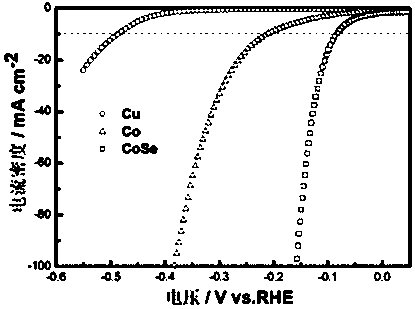

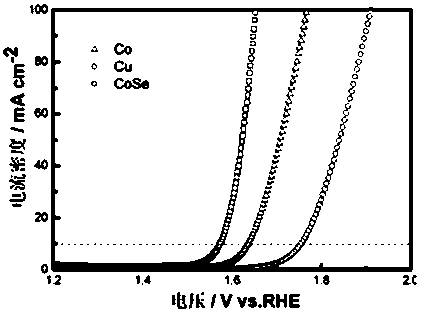

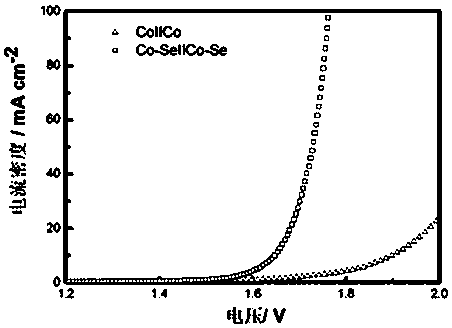

An ionic liquid and nanoporous technology, applied in chemical instruments and methods, chemical/physical processes, electrodes, etc., can solve the problems that limit the wide application of cobalt selenide, complicated process, poor controllability, etc., and achieve uniform and dense surface, Simple process and good product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A method for preparing nanoporous cobalt selenide by electrodeposition in a deep eutectic ionic liquid, the specific steps of which are as follows:

[0023] (1) Electrolyte configuration: Mix choline chloride and urea in a molar ratio of 1:2 to obtain a deep eutectic ionic liquid, then add cobalt chloride hexahydrate and selenium dioxide to 50 mL of eutectic ionic liquid In the type ionic liquid, the ionic liquid cobalt salt-selenium dioxide electrolyte system with a cobalt concentration of 0.05mol / L and a selenium concentration of 0.01mol / L was obtained after fully stirring and mixing;

[0024] (2) Surface treatment of the working electrode: take the copper substrate as the working electrode, wash it repeatedly with dilute hydrochloric acid with a mass percentage concentration of 1%, ultrasonication with absolute ethanol, and deionized water, and then dry it for later use;

[0025] (3) Constant potential electrodeposition: use a three-electrode system, use a platinum e...

Embodiment 2

[0029] A method for preparing nanoporous cobalt selenide by electrodeposition in a deep eutectic ionic liquid, the specific steps of which are as follows:

[0030] (1) Electrolyte configuration: Mix choline chloride and urea evenly at a molar ratio of 1:2 to obtain a deep eutectic ionic liquid, then add cobalt chloride hexahydrate and selenium dioxide to 45mL eutectic ionic liquid In the type ionic liquid, the ionic liquid cobalt salt-selenium dioxide electrolyte system with a cobalt concentration of 0.05mol / L and a selenium concentration of 0.01mol / L was obtained after fully stirring and mixing;

[0031] (2) Surface treatment of the working electrode: take the copper substrate as the working electrode, wash it repeatedly with dilute hydrochloric acid with a mass percentage concentration of 1%, ultrasonication with absolute ethanol, and deionized water, and then dry it for later use;

[0032] (3) Constant potential electrodeposition: using a three-electrode system, using graph...

Embodiment 3

[0035] A method for preparing nanoporous cobalt selenide by electrodeposition in a deep eutectic ionic liquid, the specific steps of which are as follows:

[0036] (1) Electrolyte configuration: Tetramethylammonium chloride and acetamide were mixed uniformly at a molar ratio of 1:4 to obtain a deep eutectic ionic liquid, and then cobalt sulfate and selenium dioxide were added to 40 mL of a deep eutectic ionic liquid In the liquid, after fully stirring and mixing uniformly, an ionic liquid cobalt salt-selenium dioxide electrolyte system with a cobalt concentration of 0.05mol / L and a selenium concentration of 0.025mol / L is obtained;

[0037](2) Surface treatment of the working electrode: take the copper substrate as the working electrode, wash it repeatedly with dilute hydrochloric acid with a mass percentage concentration of 1%, ultrasonication with absolute ethanol, and deionized water, and then dry it for later use;

[0038] (3) Constant potential electrodeposition: using a t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com