Catalyst for VIII group single atomic dispersion and preparation method thereof

An atomic dispersion, catalyst technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as unreported, poor catalyst stability, high price, etc., and achieve a simple and easy preparation method. performance, good stability and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

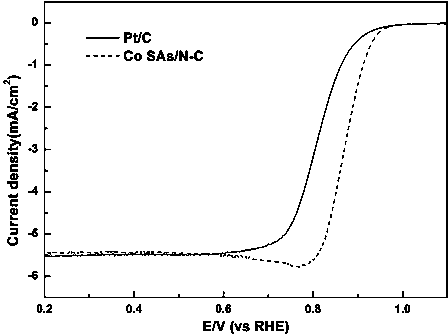

[0024] Preparation of Co single-atom dispersed catalyst:

[0025] (1) Prepare 0.125mol / L methanol solution of zinc nitrate hexahydrate, 0.125mol / L methanol solution of cobalt nitrate hexahydrate, and 0.5mol / L methanol solution of dimethylimidazole; Zinc nitrate methanol solution and n milliliters of 0.125mol / L cobalt nitrate hexahydrate methanol solution were mixed and then added to 2n milliliters of dimethylimidazole methanol solution, dissolved while ultrasonic, and then the mixed solution was stirred overnight;

[0026] (2) The obtained mixed solution was centrifuged and washed with methanol for 3-5 times, and dried overnight in an oven at 70°C to obtain a solid powder;

[0027] (3) Put the obtained solid powder into a porcelain boat, put the porcelain boat into a tube furnace, seal it and pass in an inert gas, heat up to 900°C under an inert atmosphere, calcinate for 3 hours, then cool down to room temperature naturally, and take it out in agate Grind in a mortar for 30mi...

Embodiment 2

[0029] Preparation of Ni single-atom dispersed catalyst:

[0030] The difference from Example 1 is: change cobalt nitrate hexahydrate into nickel nitrate hexahydrate.

Embodiment 3

[0032] Catalyst preparation of Fe, Co double monatomic dispersion:

[0033] The difference from Example 1 is: the metal organic framework obtained in Example 1 was dispersed in n-hexane, then 100ul (10-100mg / ml) of ferric chloride aqueous solution was added, stirred for 1-3h, washed and dried, and then The obtained sample was put into a tube furnace for calcination at 900°C for 2 hours to obtain a Fe, Co double monatomic dispersed catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com