Phosphorus-free scale and corrosion inhibitor and preparation method thereof

A phosphorus-free scale and corrosion inhibitor technology, applied in the preparation of phosphorus-free scale and corrosion inhibitors, water treatment chemicals, phosphorus-free scale and corrosion inhibitors, can solve eutrophication pollution, non-compliance with environmental protection policies, etc. problems, to achieve the effect of strong corrosion resistance, remarkable pollution repelling effect, and fast film forming speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

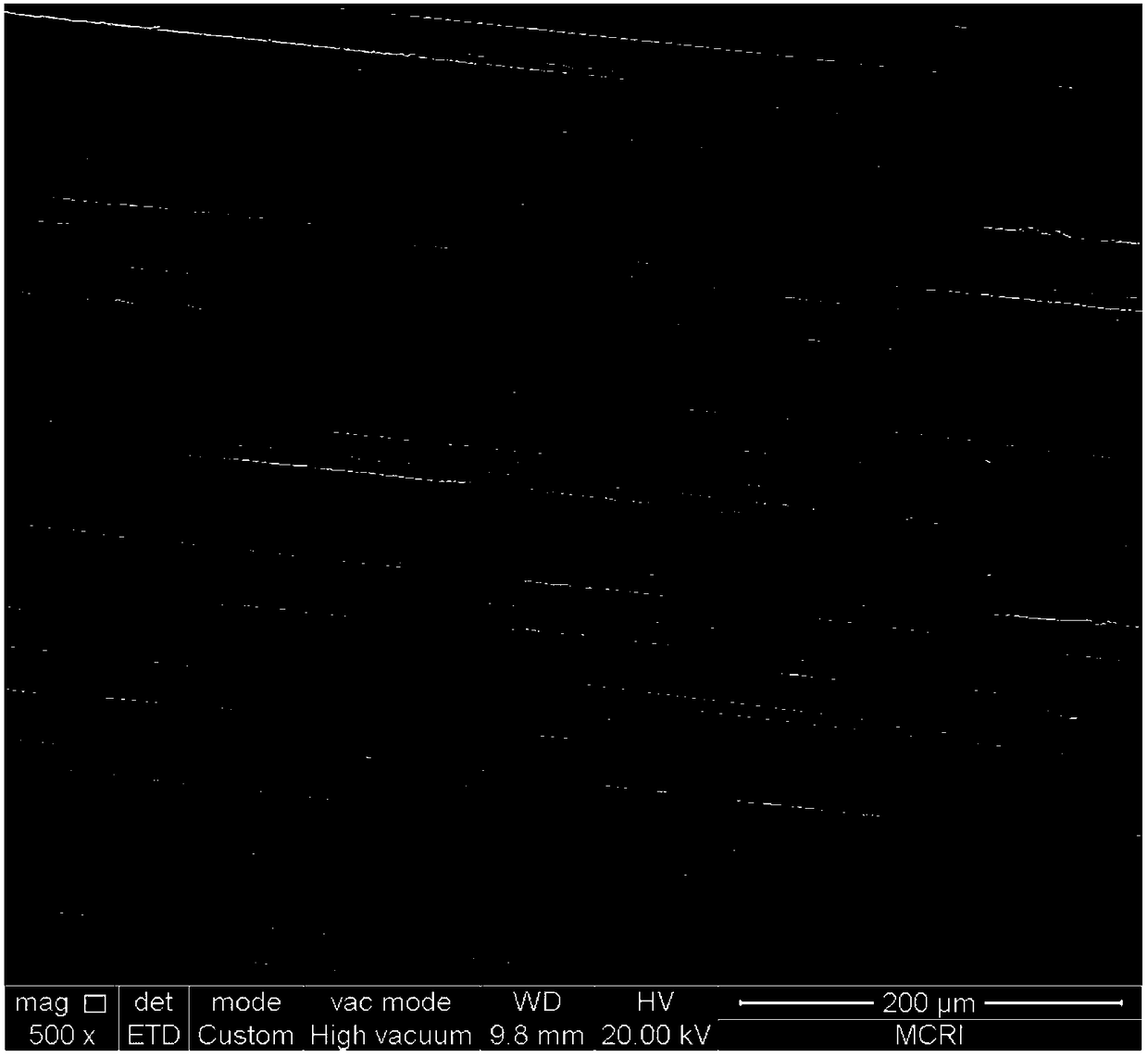

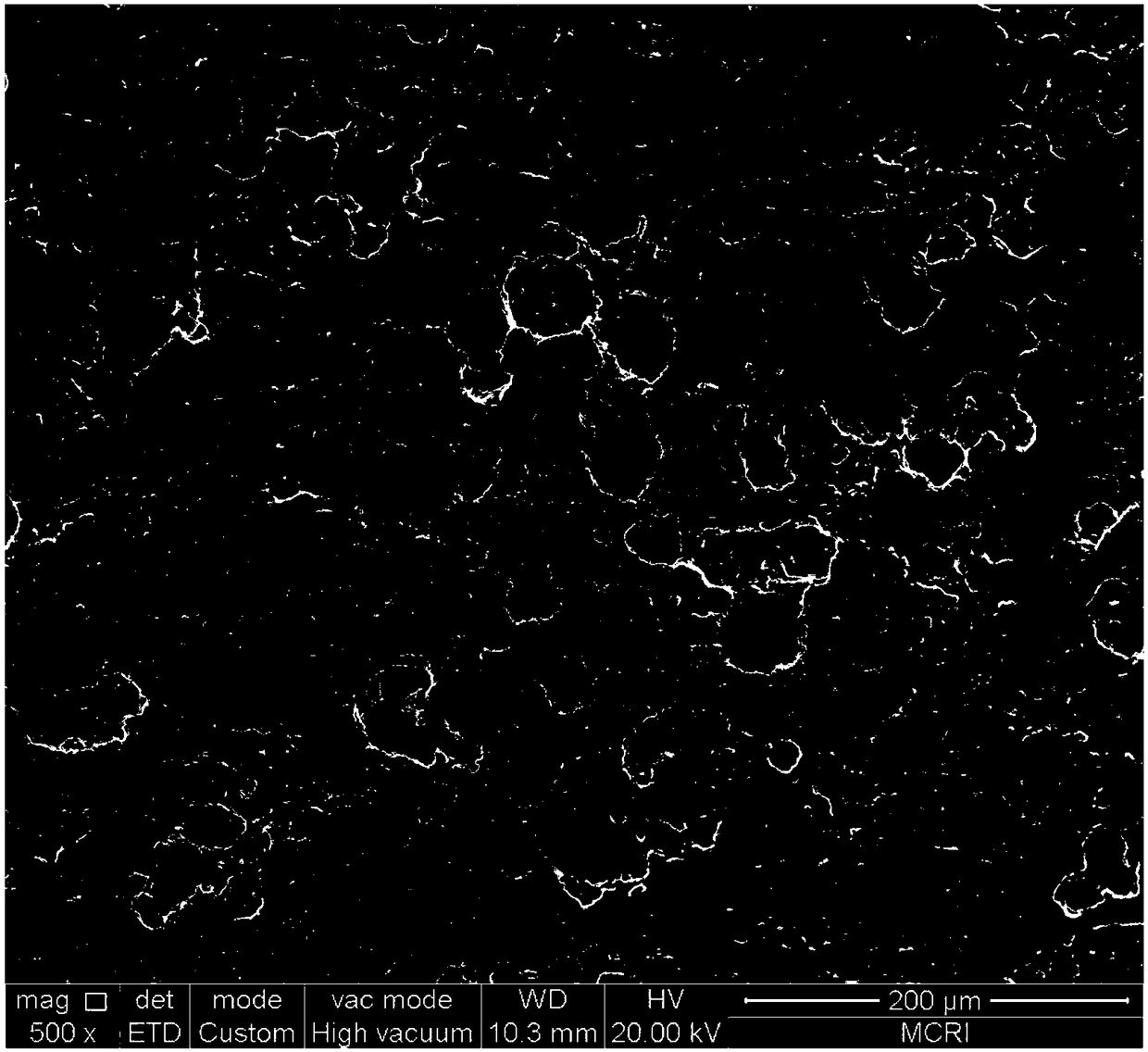

Image

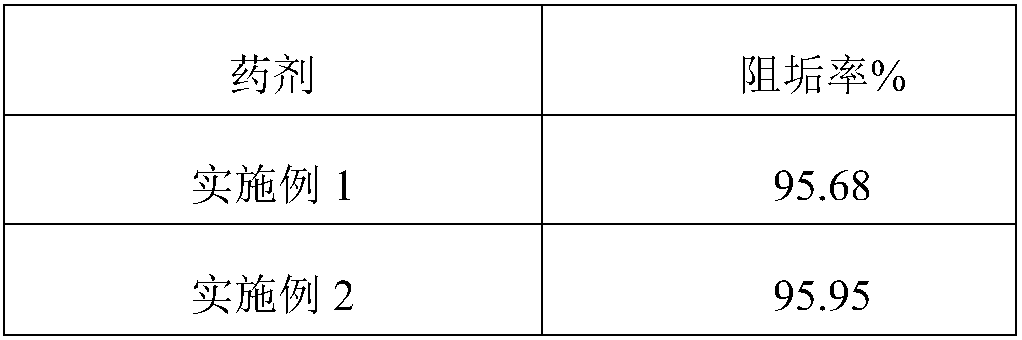

Examples

Embodiment 1

[0029] This example provides a phosphorus-free scale and corrosion inhibitor for circulating cooling water system, the mass percentage of each component is as follows:

[0030]Lactic acid: 12%;

[0031] Hydrolyzed polymaleic anhydride: 18%;

[0032] Polyepoxysuccinic acid: 10%

[0033] Disodium EDTA: 5%;

[0036] Sodium hydroxyethyl cellulose: 0.2%;

[0037] Deionized water: 45.8%.

[0038] The preparation method of the phosphorus-free scale and corrosion inhibitor described in this embodiment:

[0039] First, add 0.2g sodium hydroxyethylcellulose and 45.8g deionized water into the stirring reactor according to the proportion, start stirring, and after the sodium hydroxyethylcellulose is completely dissolved, add 5g disodium edetate, After 4g of zinc chloride is completely dissolved, add 12g of lactic acid, 18g of hydrolyzed polymaleic anhydride, 10g of polyepoxysuccinic acid, and 5g of sodium hydroxide in propo...

Embodiment 2

[0041] This example provides a phosphorus-free scale and corrosion inhibitor for circulating cooling water system, the mass percentage of each component is as follows:

[0042] Tartaric acid: 20%;

[0043] Hydrolyzed polymaleic anhydride: 15%;

[0044] Polyaspartic acid: 10%

[0045] Citric acid: 5%;

[0046] Potassium hydroxide: 4%;

[0048] Sodium hydroxypropyl methylcellulose: 0.5%;

[0049] Deionized water: 42.5%

[0050] The preparation method of the phosphorus-free scale and corrosion inhibitor described in this embodiment:

[0051] First, add 0.5g sodium hydroxypropyl methylcellulose and 42.5g deionized water into the stirring reactor according to the proportion, start stirring, and after the sodium hydroxypropyl methylcellulose is completely dissolved, add 5g citric acid, 3g After zinc sulfate is completely dissolved, add 20g of tartaric acid, 15g of hydrolyzed polymaleic anhydride, 10g of polyaspartic acid, and 4g of potassium hydroxi...

Embodiment 3

[0053] This example provides a phosphorus-free scale and corrosion inhibitor for circulating cooling water system, the mass percentage of each component is as follows:

[0054] Salicylic Acid: 25%;

[0055] Hydrolyzed polymaleic anhydride: 10%;

[0056] Acrylic copolymer: 20%

[0057] Sodium iminodisuccinate: 3%;

[0058] Potassium hydroxide: 6%;

[0060] Sodium hydroxymethylcellulose: 1%;

[0061] Deionized water: 33%

[0062] Wherein the acrylic acid copolymer is a terpolymer, specifically: acrylic acid-hydroxypropyl acrylate-styrenesulfonic acid copolymer.

[0063] The preparation method of the phosphorus-free scale and corrosion inhibitor described in this embodiment:

[0064] First, add 1g sodium hydroxymethylcellulose and 33g deionized water into the stirring reactor according to the proportion, start stirring, and after the sodium hydroxymethylcellulose is completely dissolved, add 3g sodium iminodisuccinate, 2g a After the zinc sulfat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com