Environment-friendly type starch adhesive for decoration and preparation method thereof

A starch glue, environmentally friendly technology, applied in the direction of adhesives, non-polymer adhesive additives, adhesive additives, etc., can solve the problems of poor storage stability of glue, poor dilution film-forming, slow drying speed, etc. Good polishing, high bonding strength, good brushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

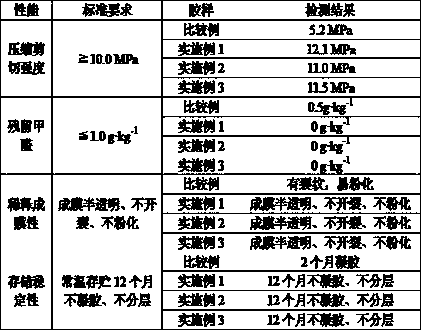

Examples

Embodiment 1

[0050] An environmentally friendly starch glue that can be used for decoration and a preparation method thereof, its components and specific proportions constitute:

[0051] Polyvinyl alcohol 2088 11.3g;

[0052] Vinyl acetate monomer 18.4g;

[0053] Acrylic acid monomer 0.4g;

[0054] Cornstarch 20.6g

[0055] Light calcium carbonate 7.2g;

[0056] Ammonium persulfate 0.4g;

[0057] Plasticizer DEDB 2.2g;

[0058] Disodium edetate 0.4g;

[0059] Sodium acetate 3.0g;

[0060] Defoamer DAPRO AP 7072 0.6g;

[0061] Bactericide Defros BM 0.5g;

[0062] Deionized water 239.0g.

[0063] The concrete steps of preparation method are as follows:

[0064] a. Disperse, add cornstarch to deionized water, and disperse for 15 minutes;

[0065] b. To dissolve, add polyvinyl alcohol 2088, and keep warm at 80-90°C for 1 hour until the polyvinyl alcohol 2088 is completely dissolved;

[0066] c. Polymerization, the internal temperature drops to 80°C, add disodium edetate (metal ion ...

Embodiment 2

[0070] An environmentally friendly starch glue that can be used for decoration and a preparation method thereof, its components and specific proportions constitute:

[0071] Sodium polyacrylate 4.2g;

[0072] Emulsifier NP-10 8.6g;

[0074] Butyl acrylate monomer 22.8g;

[0075] Methacrylic acid monomer 1.0g;

[0076] Methyl methacrylate monomer 2.0g;

[0077] Potato starch 19.5g;

[0078] Ground calcium carbonate 8.4g;

[0079] Potassium persulfate 0.5g;

[0080] Plasticizer TEDB 1.8g;

[0081] Defoamer DAPRO AP 7072 0.8g;

[0082] Fungicide parmetol K40 0.6g;

[0083] Deionized water 208.0g.

[0084] The concrete steps of preparation method are as follows:

[0085] a. Disperse, add potato starch into deionized water, and disperse for 15 minutes;

[0086] b. Dissolve, add sodium polyacrylate, keep warm at 80-90°C for 1 hour until all sodium polyacrylate is dissolved;

[0087] c. Polymerization, the internal temperature drops to 85°C,...

Embodiment 3

[0091] An environmentally friendly starch glue that can be used for decoration and a preparation method thereof, its components and specific proportions constitute:

[0092] Sodium polyacrylate 12.6g;

[0093] Emulsifier NP-10 11.4g;

[0094] Butyl acrylate monomer 15.8g;

[0095] Acrylic acid monomer 1.0g;

[0096] Methyl methacrylate monomer 30.5g;

[0097] Rice starch 17.0g;

[0099] Ammonium persulfate 0.5g;

[0100] Plasticizer DEDB 2.0g;

[0101] Fungicide Defros M-10 0.5g;

[0102] Deionized water 198g.

[0103] The concrete steps of preparation method are as follows:

[0104] a. Disperse, add rice starch into deionized water, and disperse for 15 minutes;

[0105] b. Dissolve, add sodium polyacrylate, keep warm at 80-90°C for 1 hour until all sodium polyacrylate dissolves;

[0106] c. Polymerization, the internal temperature drops to 86°C, add emulsifier NP-10 and 1 / 2 ammonium persulfate aqueous solution, after 15 minutes of reacti...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap