Method for preparing supported molecular sieve catalyst by using vacuum impregnation method

A vacuum impregnation and molecular sieve technology, applied in molecular sieve catalysts, including molecular sieve catalysts, catalysts, etc., can solve the problems of easy carbon deposition and deactivation, low propylene selectivity, etc., and achieve good carbon deposition resistance, high selectivity, and low additional The effect of less by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

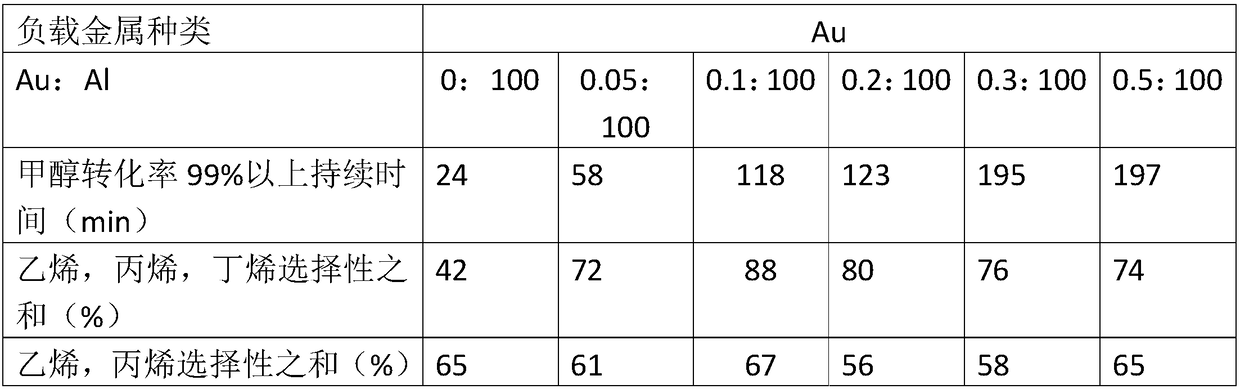

Embodiment 1

[0030] Au-MCM-41 / SAPO-34 molecular sieve with core-shell structure prepared by vacuum impregnation method:

[0031] (1) Put 10mL of cetyltrimethylammonium bromide in the alkaline solution formed by mixing 100mL of distilled water and 10mL of concentrated ammonia water, and stir in a water bath at 50-60°C until completely dissolved; Slowly add ethyl orthosilicate dropwise until a white precipitate is formed, continue stirring for 3 hours, cool to room temperature, and crystallize at room temperature for 3 days, then filter with suction, wash with absolute ethanol and distilled water until the filtrate is neutral, and use Dry in a vacuum oven at 100°C to obtain the original powder of MCM-41 mesoporous molecular sieve.

[0032] (2) The original powder of MCM-41 mesoporous molecular sieve obtained in step (1) is used as silicon source, pseudo-boehmite is added as aluminum source, and phosphoric acid, TEA template agent and water are added to mix and stir for more than 0.5h to form c...

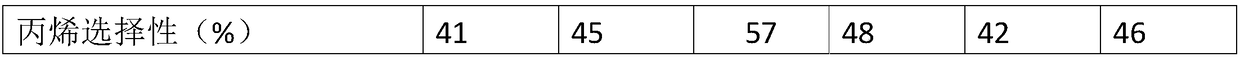

Embodiment 2

[0047] Au-SBA-15 / SAPO-34, a core-shell structure molecular sieve containing Au, was prepared by vacuum impregnation method:

[0048] (1) Put 10g of polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer in an alkaline solution formed by mixing 100mL of distilled water and 10mL of concentrated ammonia water, and stir in a water bath at 55°C until completely dissolved ; Then slowly drop tetraethyl orthosilicate at a speed of 1mL / min until a white precipitate is generated, continue to stir and react for 3h, cool to room temperature, and suction filter after crystallization at room temperature for 3 days, and use absolute ethanol and distilled water Wash until the filtrate is neutral, and dry it in a vacuum oven at 100°C to obtain the original powder of SBA-15 mesoporous molecular sieve.

[0049] (2) The original powder of SBA-15 mesoporous molecular sieve obtained in step (1) was used as silicon source, pseudoboehmite was added as aluminum source, and phosph...

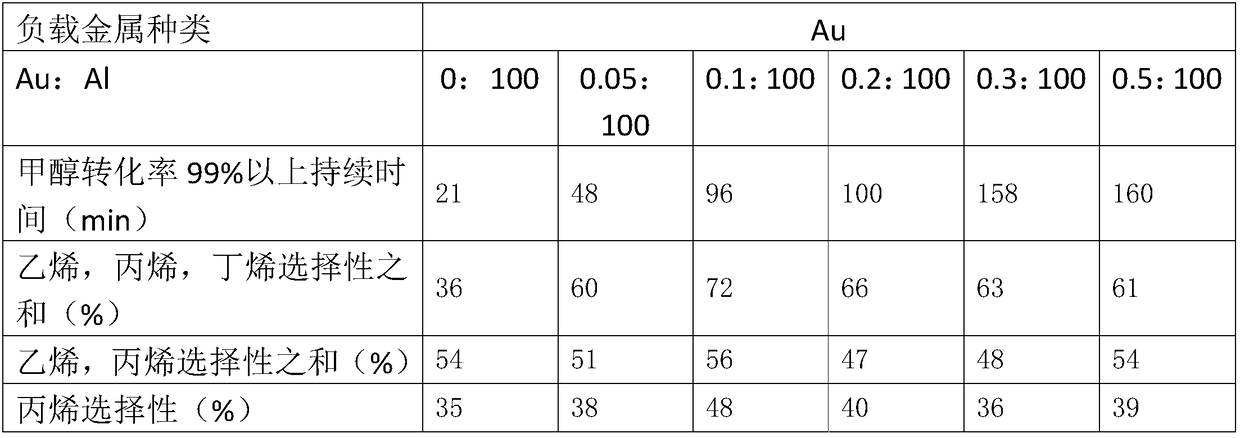

Embodiment 3

[0063] Prepare the molecular sieve Pt-MCM-41 / SAPO-34 containing Pt core-shell structure, replace the metal sol with chloroplatinic acid, and the rest of the preparation method is the same as in Example 1.

[0064] Reaction condition is with implementation example 1. The activity evaluation results of the loaded molecular sieve prepared by vacuum impregnation method are shown in Table 3

[0065] table 3

[0066]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com