A method for preparing low-cobalt, ultrafine-grained cemented carbide rods with nano-wc-co composite powder

A cemented carbide rod and composite powder technology, which is applied in metal processing equipment, transportation and packaging, etc., can solve the problems of uneven growth of alloys, uneven mixing, and dirty materials, so as to reduce sintering activity and reduce sintering. Powder active, uniform distribution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

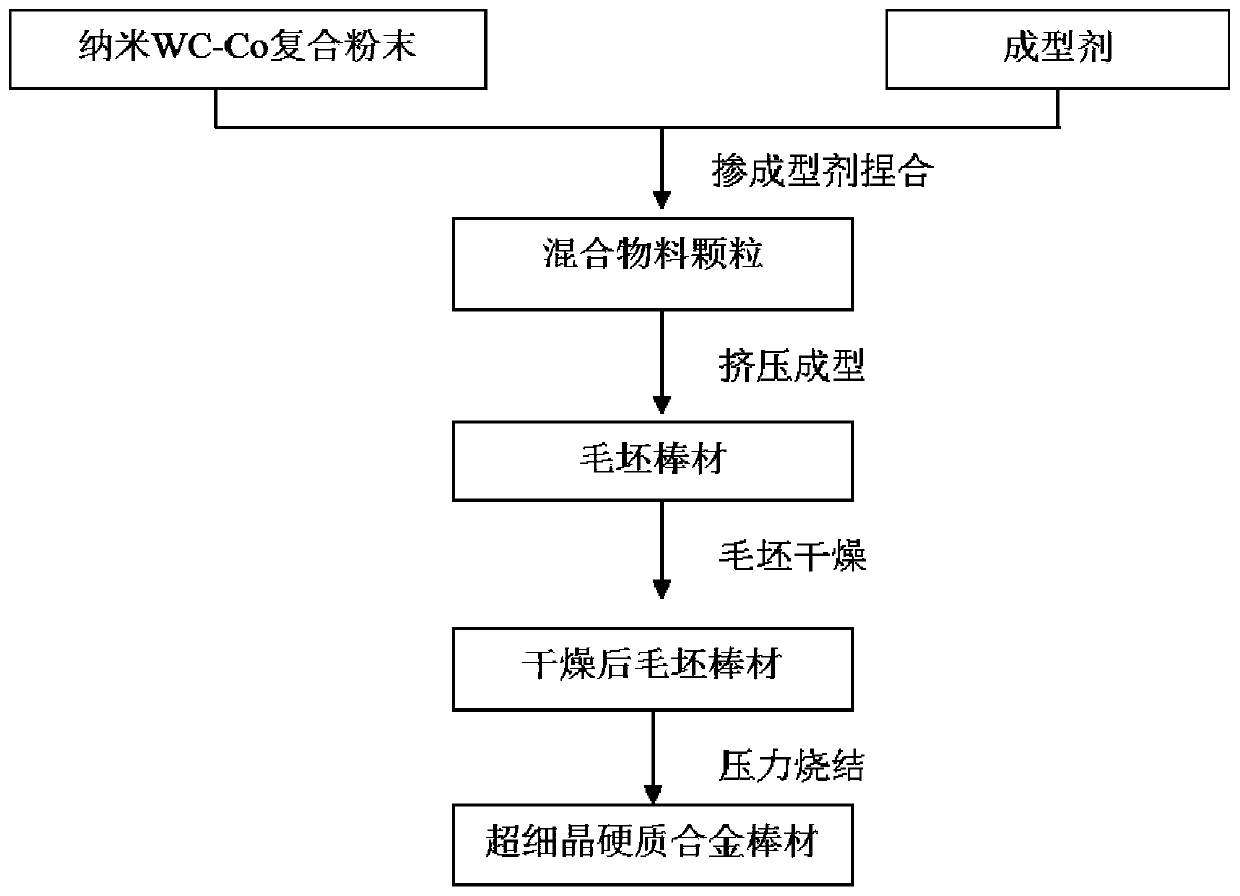

[0051] The present embodiment prepares ultra-fine-grained cemented carbide rods according to the following steps:

[0052] 1) Kneading with molding agent

[0053] Select nano-WC-6Co composite powder with Co-coated WC grain size ≤ 200nm and Co mass content of 6%;

[0054] Add 1.32kg of tetralin, 0.35kg of cellulose, 0.03kg of soybean ammonium, and 0.34kg of paraffin into a stirrer heated to 100°C, heat and stir until a clear, bubble-free sol state is obtained to obtain a molding agent;

[0055] Add 30kg of nano WC-6Co composite powder into the kneader, and then add the forming agent; start the kneader, evacuate for 5 minutes, then heat, set the temperature to 60°C for 3 hours, keep stirring during the heating process; then stir and knead at a constant temperature of 60°C 1 hour; finally water cooling for 45 minutes, stirring and crushing during the cooling process to obtain mixed material granules.

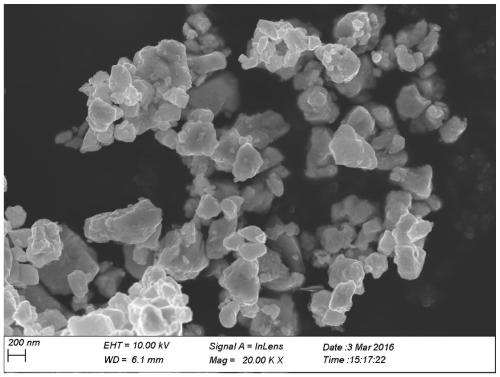

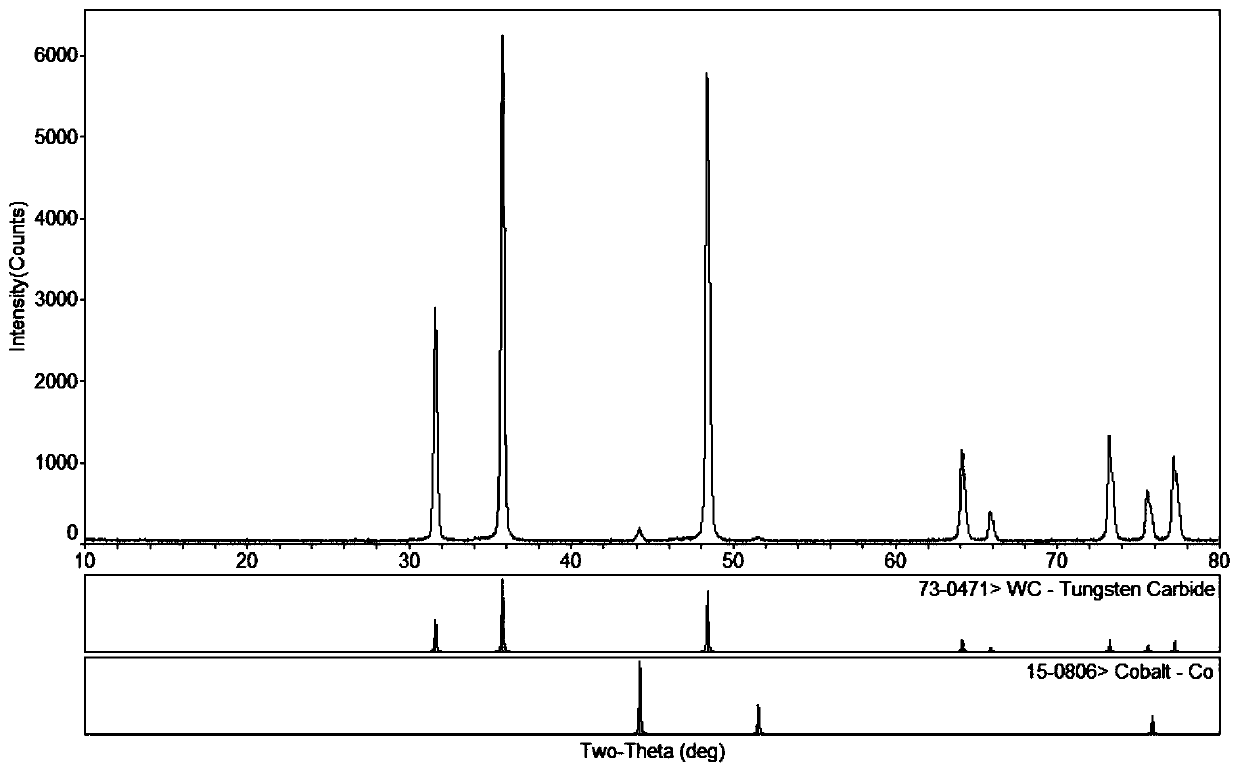

[0056] The SEM image of the raw material nano WC-6Co composite powder used i...

Embodiment 2

[0082] The present embodiment prepares ultra-fine-grained cemented carbide rods according to the following steps:

[0083] 1) Kneading with molding agent

[0084] Select nano-WC-3Co composite powder with Co-coated WC grain size ≤ 200nm and Co mass content of 3%;

[0085] Add 1.42kg of tetralin, 0.40kg of cellulose, 0.036kg of soybean ammonium, and 0.45kg of paraffin into a stirrer heated to 100°C, heat and stir until a clear, bubble-free sol state is obtained to obtain a molding agent;

[0086] Add 30kg of nano WC-3Co composite powder into the kneader, and then add the forming agent; start the kneader, evacuate for 5 minutes, then heat, set the temperature to 60°C for 3 hours, keep stirring during the heating process; then stir and knead at a constant temperature of 60°C 1 hour; finally water cooling for 45 minutes, stirring and crushing during the cooling process to obtain mixed material granules.

[0087] 2) Extrusion molding

[0088] Get 30kg of the mixed material granul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com