Catalytic hydrodechlorination Pd-M/NOMC catalyst and preparing method and application thereof

A technology for catalytic hydrogenation and catalysts, applied in chemical instruments and methods, preparation of organic compounds, alkali metal oxides/hydroxides, etc. Easier control, less damage, improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

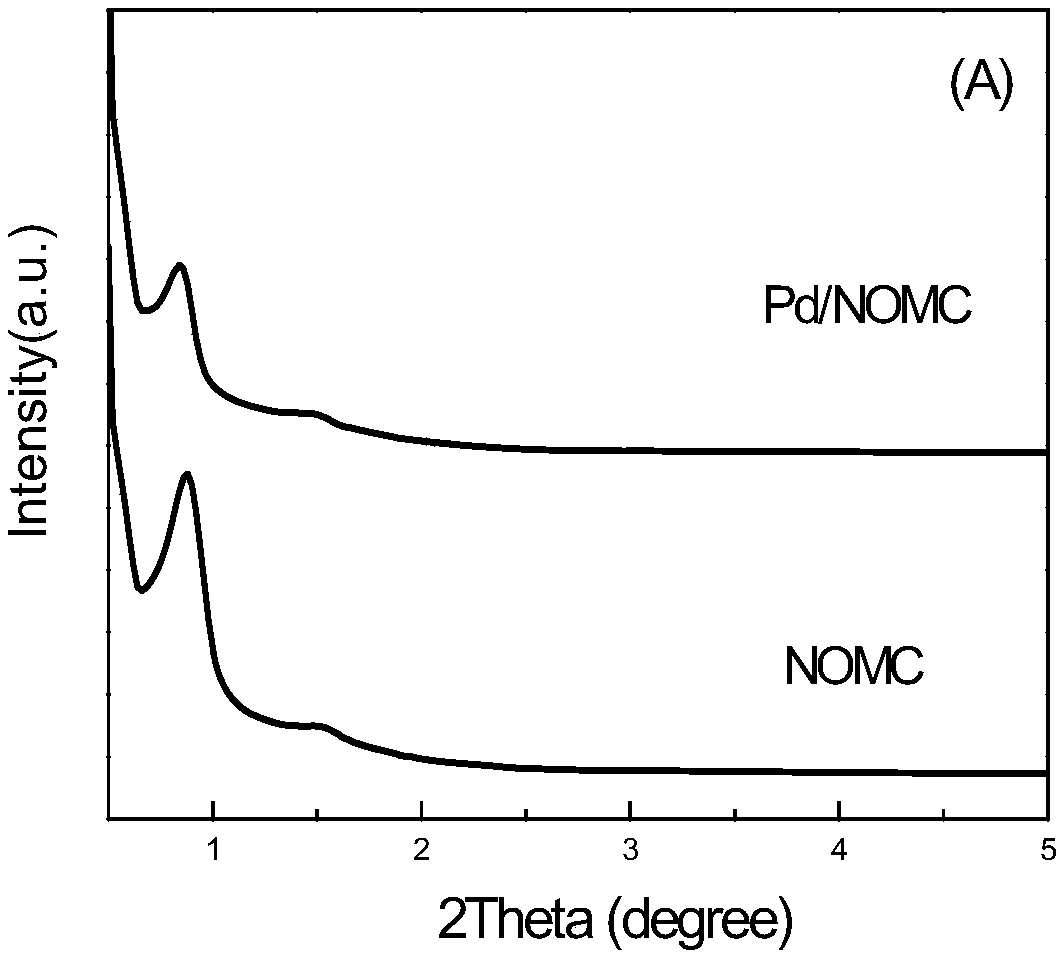

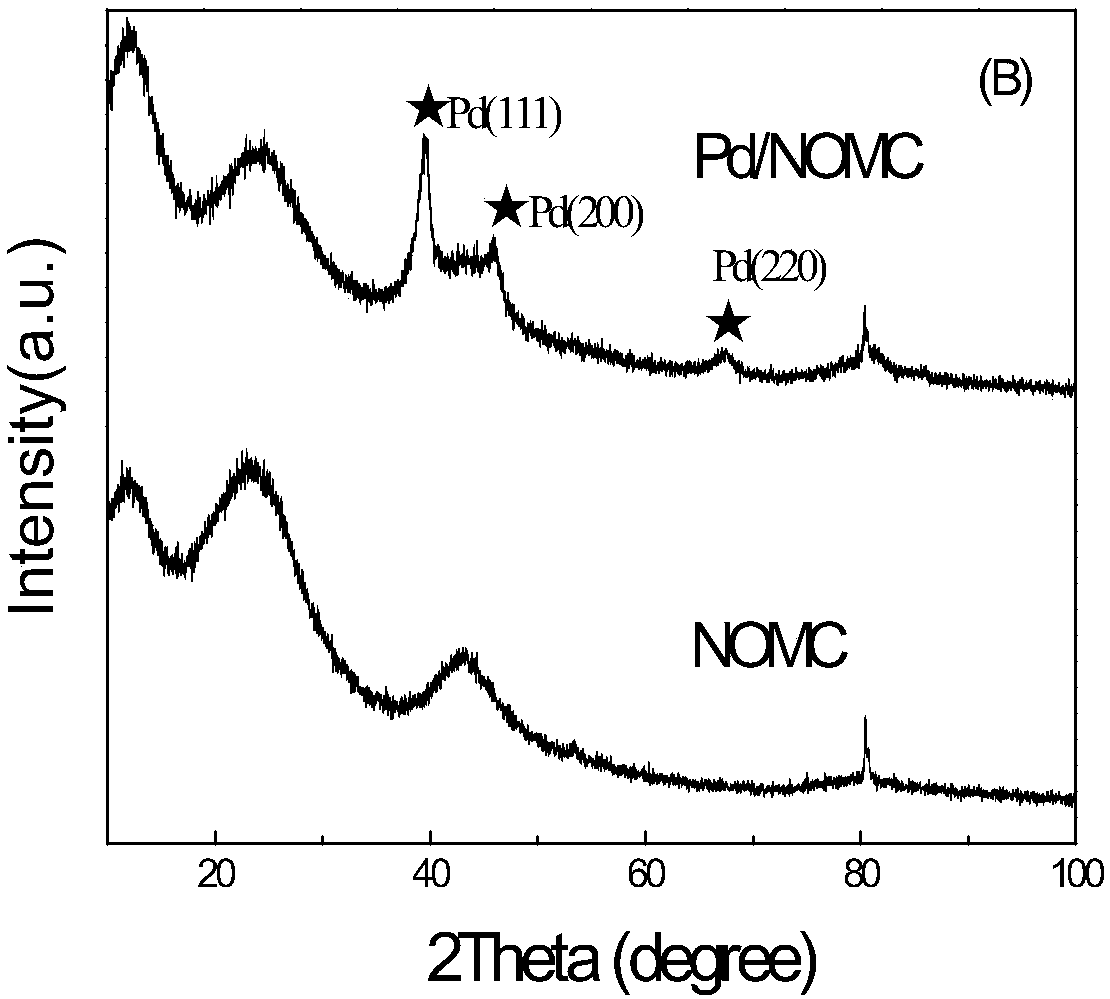

Image

Examples

Embodiment 1

[0028] 1. Weigh about 6.70 grams of resorcinol, 4.50 grams of hexamethylenetetramine (HMT), 13.00 grams of F127, 2.50 grams of tetramethylbenzidine (TMB), 300 milliliters of deionized water, 15 milliliters of hydroxide Ammonium (NH 4 OH, the weight percent is 28), 5.00 g of urea, and stirred at room temperature for 3 h after the addition.

[0029] 2. Stir continuously for 10 hours under air reflux in an oil bath at a temperature of 85°C.

[0030] 3. After 10 hours, the solid product was taken out, centrifuged with a centrifuge, and washed four times with appropriate amounts of deionized water and ethanol solution.

[0031] 4. After centrifugation, take the sample out and place it in a watch glass, and dry it at 70-160°C for 6-16 hours.

[0032] 5. Put the dried sample in a nitrogen atmosphere at 450-1200°C (heating rate: 3°C / min) and continue roasting for 1-10h.

[0033] Finally, the catalyst was obtained, bagged, marked and sealed for storage. The amount of the catalyst wa...

Embodiment 2

[0041] 1. Weigh about 3.50 grams of resorcinol, 2.10 grams of hexamethylenetetramine (HMT), 6.20 grams of F127, 1.30 grams of tetramethylbenzidine (TMB), 158 milliliters of deionized water, and 7 milliliters of hydrogen peroxide Ammonium (NH 4 OH, the weight percent is 28), 3.6 g of urea, and stirred at room temperature for 2 h after the addition was completed.

[0042] 2. Stir continuously for 8.5 hours under air reflux in an oil bath at a temperature of 85°C.

[0043] 3. After 8.5 hours, the solid product was taken out, centrifuged with a centrifuge, and washed four times with appropriate amount of deionized water and ethanol solution respectively.

[0044] 4. After centrifugation, take the sample out and place it in a watch glass, and dry it at 58-145°C for 3-15 hours.

[0045] 5. Put the dried sample in a nitrogen atmosphere at 390-1200° C. (the heating rate is 1° C. / min) and continue roasting for 1-9 hours.

[0046] 6. Finally, get the catalyst, pack it into a bag, mark ...

Embodiment 3

[0054] 1. Weigh about 5.00 grams of resorcinol, 3.80 grams of hexamethylenetetramine (HMT), 8.10 grams of F127, 3.00 grams of tetramethylbenzidine (TMB), 220 milliliters of deionized water, 10 milliliters of hydroxide Ammonium (NH 4 OH, the weight percent is 28), 5.0 g of urea, and stirred at room temperature for 2.5 h after the addition.

[0055] 2. Stir continuously for 9 hours under air reflux in an oil bath at a temperature of 80°C.

[0056] 3. After 9 hours, the solid product was taken out, centrifuged with a centrifuge, and washed four times with appropriate amount of deionized water and ethanol solution respectively.

[0057] 4. After centrifugation, take the sample out and place it in a watch glass, and dry it at 55-140°C for 4-15 hours.

[0058] 5. Put the dried sample in a nitrogen atmosphere at 390-1200°C (heating rate: 1°C / min) and continue roasting for 1-8h.

[0059] 6. Finally, get the catalyst, put it in a bag, mark it and seal it for storage. The amount of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com