A kind of preparation method of divalent metal iron-based spinel

A bivalent metal and spinel technology, applied in chemical instruments and methods, iron compounds, nickel compounds, etc., can solve the problems of easy agglomeration in the calcination process, difficult mixing of oxygen carriers, expensive reagents, etc., and achieve good high temperature Stability and mechanical stability, not easy to agglomerate, beneficial to recycling and utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

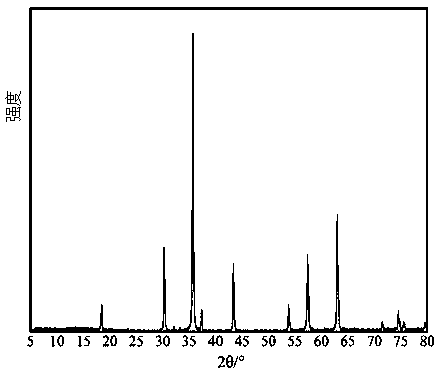

[0037] A kind of nano-nickel-iron spinel (NiFe 2 o 4 ) preparation method, comprising the following steps:

[0038] 1) Prepare 300mL of solution A, in which the molar ratio of Ni / Fe is 1:2, Ni 2+ Concentration is 0.1mol / L, Fe 3+ The concentration is 0.2mol / L; prepare 200mL of ammonium carbonate solution with a concentration of 0.5mol / L.

[0039] 2) Add 0.5mol / L ammonium carbonate solution at 5mL / min to solution A with a magnetic stirring speed of 600r / min. The initial pH of solution A before adding ammonium carbonate solution is 0.8, and the pH of the mixed solution after adding is 2.8 Left and right, the solution turns into a paste-like suspension, and after the magnetic stirring lasts for 30s, an aqueous sol with a certain solid structure is formed.

[0040] 3) Slowly dry the hydrosol in a drying oven at 105°C for 6 hours to form a transparent block-shaped dry gel; then place the dried gel in a covered crucible and heat it at 400°C for 2 hours in a muffle furnace to isol...

Embodiment 2

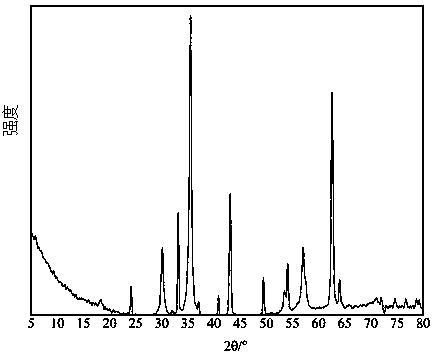

[0044] A kind of nano-magnesium iron spinel (MgFe 2 o 4 ) preparation method, comprising the following steps:

[0045] 1) Prepare 500mL of solution A, in which the molar ratio of Mg / Fe is 1:2, Mg 2+ Concentration is 1mol / L, Fe 3+ The concentration is 2mol / L; prepare 500mL of ammonium carbonate solution with a concentration of 1mol / L.

[0046] 2) Put 1mol / L ammonium carbonate solution 10mL / min into solution A with a magnetic stirring speed of 800r / min. The initial pH of solution A before adding ammonium carbonate solution is 0.01, and the pH of the mixed solution after adding is about 2. It becomes a paste-like suspension, and after magnetic stirring lasts for 60s, a hydrosol with a certain solid structure is formed.

[0047] 3) Slowly dry the hydrosol in a drying oven at 105°C for 12 hours to form a transparent block-shaped dry gel; then place the dried gel in a covered crucible and heat it at 350°C for 12 hours in a muffle furnace to isolate the air. It will be decompose...

Embodiment 3

[0051] A kind of nano copper iron spinel (CuFe 2 o 4 ) preparation method, comprising the following steps:

[0052] 1) Prepare 300mL of solution A, in which the molar ratio of Cu / Fe is 1:2, Cu 2+ Concentration is 0.5mol / L, Fe 3+ The concentration is 1mol / L; prepare 200mL of ammonium carbonate solution with a concentration of 2mol / L.

[0053] 2) Put 1mol / L ammonium carbonate solution 15mL / min into solution A with a magnetic stirring speed of 600r / min. The initial pH of solution A before adding ammonium carbonate solution is 0.5, and the pH of the mixed solution after adding is about 2.5. It becomes a paste-like suspension, and after magnetic stirring lasts for 30s, a hydrosol with a certain solid structure is formed.

[0054] 3) Slowly dry the hydrosol in a drying oven at 85°C for 12 hours to form a transparent block-shaped dry gel; then place the dried gel in a covered crucible and heat in a muffle furnace at 500°C for 2 hours in isolation from the air. It will be decompo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com