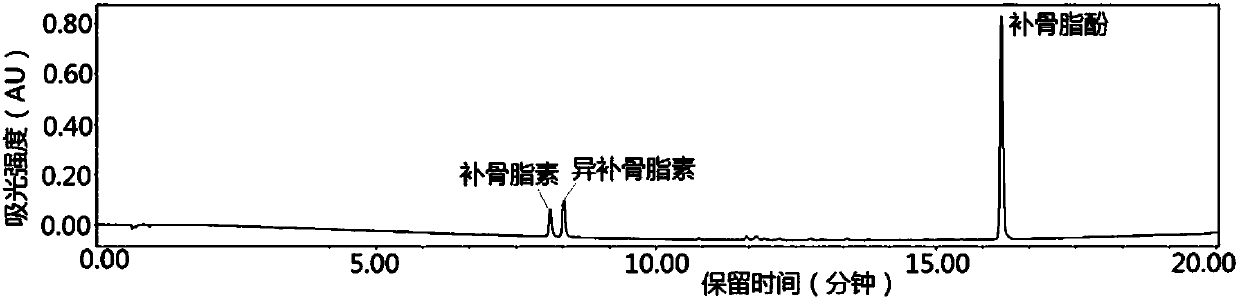

Method for separating psoralen, isopsoralen and bakuchiol from fructus psoraleae

A technology of isopsoralen and psoralen, which is applied in the field of separation and purification of natural products, can solve the problems of small preparation, cumbersome operation, loss, etc., and achieve the promotion of medicinal value, rational use of resources, and promotion of development and utilization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

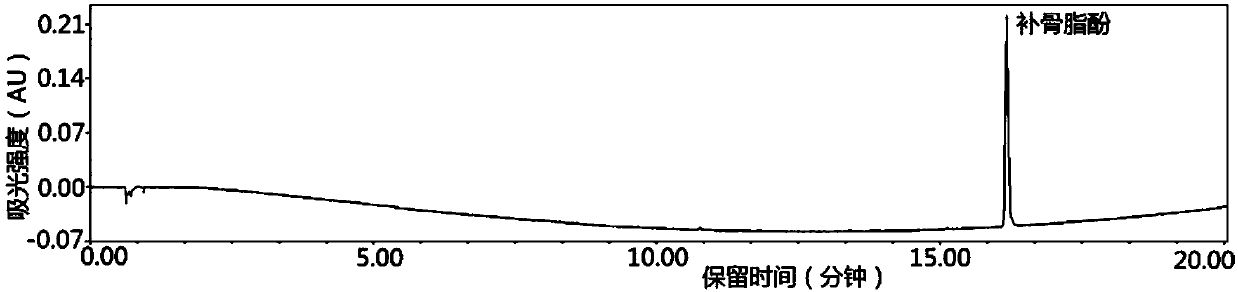

Embodiment 1

[0047] a) 500g of psoraleae medicinal material is crushed and extracted by cold soaking with 5L of petroleum ether, each cold soaking for 48 hours, repeated cold soaking and extraction 3 times, combining the extracts, filtering, and concentrating the filtrate under reduced pressure to obtain psoralen Petroleum ether crude extract 40g;

[0048] b) Polyamide column separation of the petroleum ether crude extract of psoralen: first dissolve 40 g of petroleum ether crude extract of psoralen with ethanol, and then mix with polyamide column material (100-200 mesh) according to the mass ratio of 1 Mix the sample at a ratio of 5:5 to obtain sample A. After mixing the sample, put it on the polyamide column by dry method. The weight ratio of sample A to the polyamide column material used in the polyamide column is 1:1; use ethanol and water according to 5:95~ The mixed solution formed at a volume ratio of 30:70 was sequentially eluted by gradient, analyzed by TLC, and the target fractio...

Embodiment 2

[0056] a) 500g of psoraleae medicinal material is crushed and extracted by cold soaking with 4L of petroleum ether, each cold soaking is 36 hours, and the cold soaking extraction is repeated 5 times, the extracts are combined, filtered, and the filtrate is concentrated under reduced pressure to obtain psoralen Petroleum ether crude extract 45g;

[0057] b) Polyamide column separation of the petroleum ether crude extract of psoralen: first dissolve 45g of petroleum ether crude extract of psoralen with ethanol, and then mix with polyamide column material (100-200 mesh) according to the mass ratio of 1 Mix the sample at a ratio of :3 to obtain sample A. After mixing the sample, put it on the polyamide column by dry method. The weight ratio of sample A to the polyamide column material used in the polyamide column is 1:2; use ethanol and water according to 10:90~ The mixed solution formed at a volume ratio of 25:75 was sequentially eluted by gradient, analyzed by TLC, and the targe...

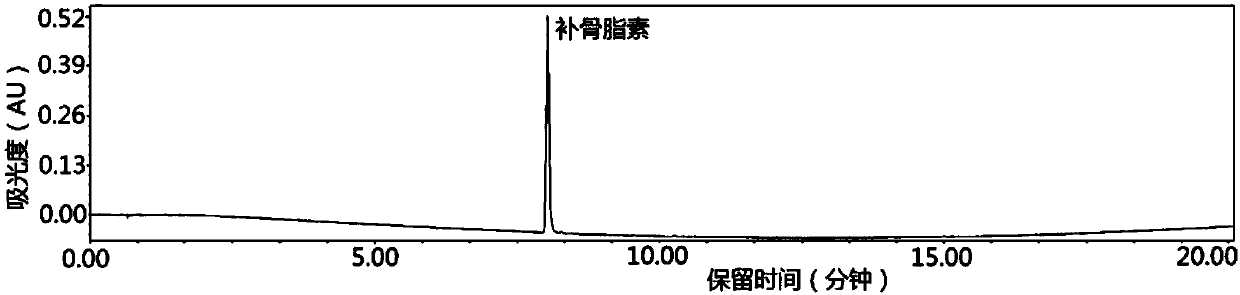

Embodiment 3

[0061] a) 500g of psoraleae medicinal material is pulverized and ultrasonically extracted with 5L of petroleum ether, the ultrasonic power is 85kHz, each ultrasonic extraction is 60 minutes, the solvent temperature is 25°C, the extraction is repeated 3 times, the extracts are combined, filtered, and the filtrate is reduced Concentrate under pressure to obtain the petroleum ether crude extract 48g of Psoraleae;

[0062] b) Polyamide column separation of the petroleum ether crude extract of psoralen: first dissolve 48g of petroleum ether crude extract of psoralen with ethanol, and then mix with polyamide column material (100-200 mesh) according to the mass ratio of 1 Mix the sample at a ratio of :3 to obtain sample A. After mixing the sample, put it on the polyamide column by dry method. The weight ratio of sample A to the polyamide column material used in the polyamide column is 1:2; use ethanol and water according to 10:90~ The mixed solution formed at a volume ratio of 25:75 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com