Phosphorus, nitrogen and silicon-containing polymer modified graphene oxide flame retardant and preparation method thereof

A polymer and oxide stone technology, applied in the field of flame retardants, can solve the problem that small molecule modified graphene cannot fully solve the problem of dispersion, and achieve the effects of wide range of use, good flame retardancy and reduced addition amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

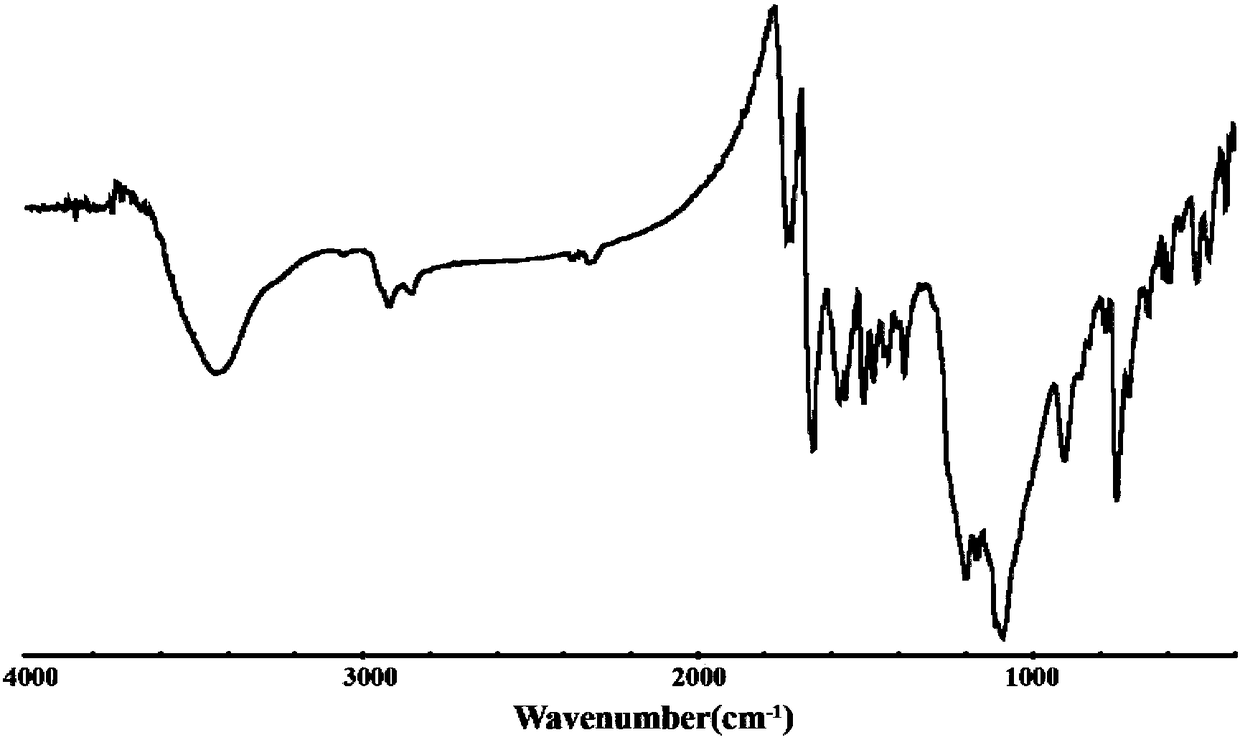

Method used

Image

Examples

Embodiment 1

[0028] (1) Synthesis of the first polymerized monomer (MAdiDOPO) (reference: CN104262398A).

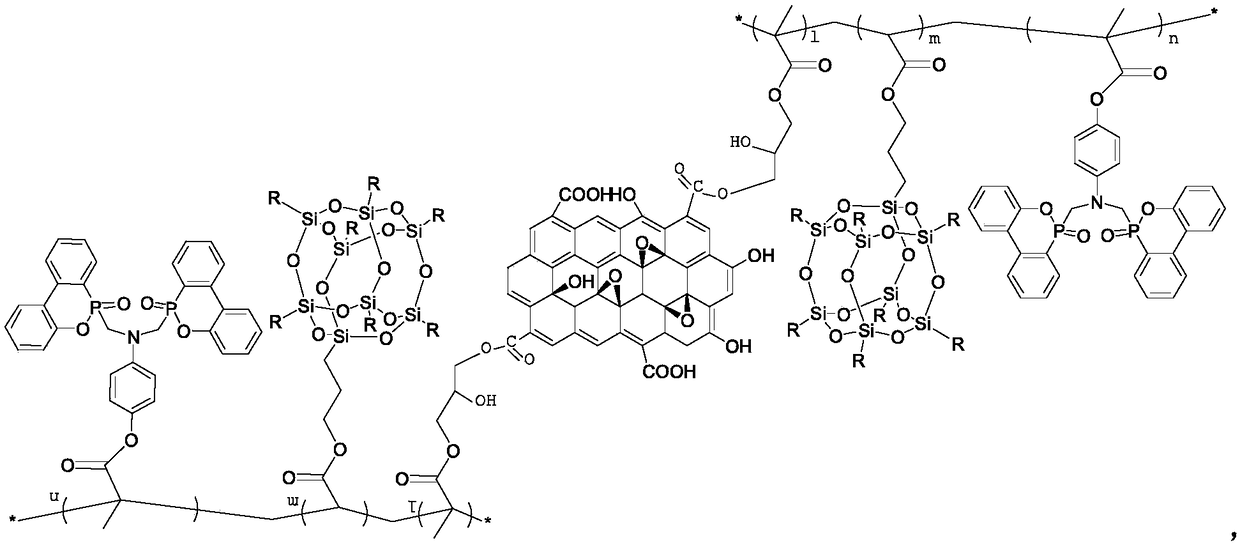

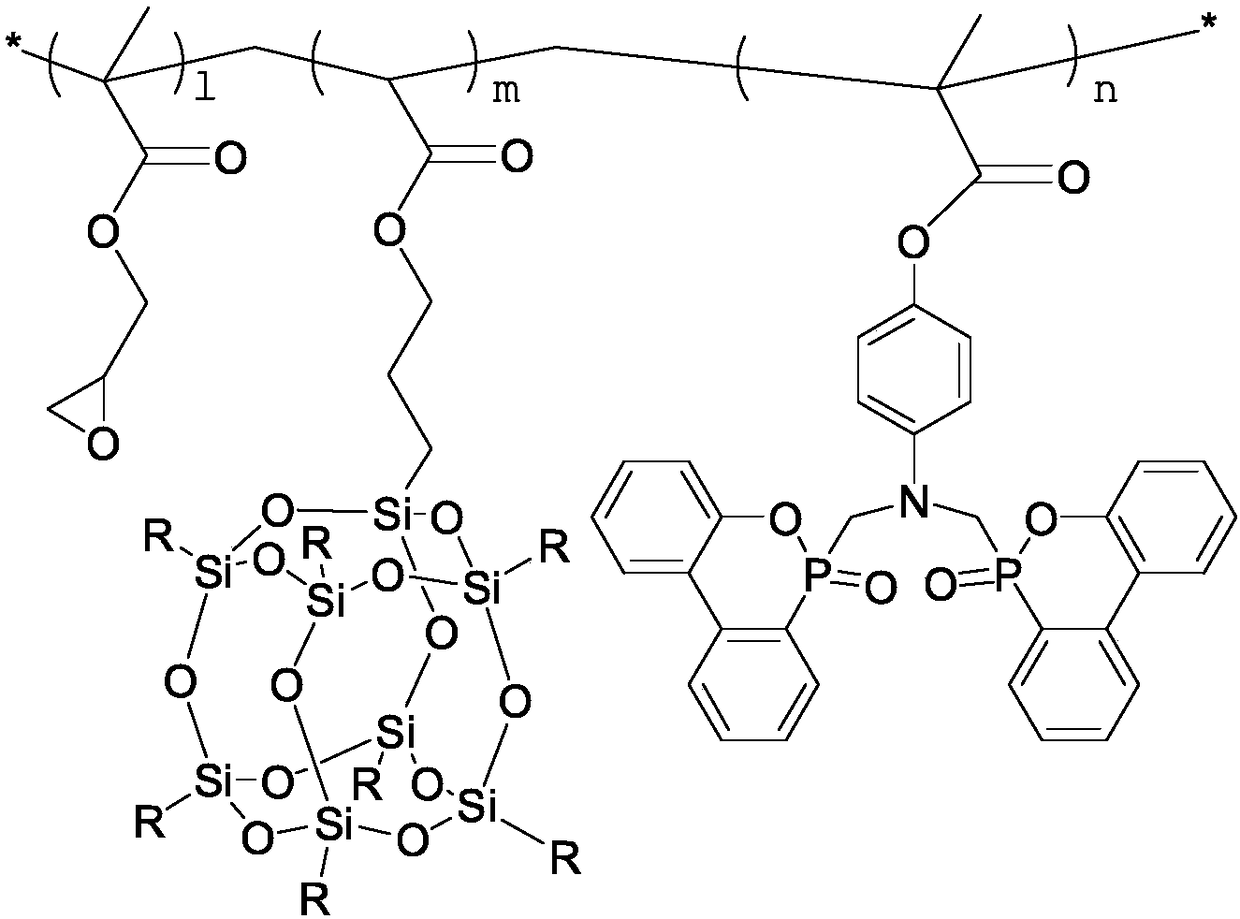

[0029] (2) Synthesis of the phosphorus-nitrogen-containing silicon polymer (PGMA-co-PMAPOSS-co-PMAdiDOPO):

[0030] First, 2.56g (18mmol) GMA, 16.98g (18mmol) MAPOSS, 22.7g (36mmol) MAdiDOPO (i.e. 1:m:n=10:10:20) and 0.08gAIBN were dissolved in tetrahydrofuran, and after nitrogen gas The oxygen in the solvent was removed by bubbling, and the reaction was carried out at 65°C for 24h. After the reaction, precipitate with methanol for 2 to 3 times to obtain a white powdery solid, which is a silicon-phosphorus-nitrogen-containing polymer.

[0031] (3) Synthesis of the phosphorus-nitrogen-silicon polymer modified graphene oxide flame retardant:

[0032] Get 10g step (2) synthetic phosphorus-nitrogen silicon polymer (PGMA-co-PMAPOSS-co-PMAdiDOPO) 0.1g catalyst tetraoctyl ammonium bromide and 2g graphene oxide are dissolved in N,N-dimethylformamide After 2 hours of ultrasonic dispersion, ...

Embodiment 2~8

[0035] The synthesis operation of the phosphorus-nitrogen-silicon-containing polymer-modified graphene oxide is the same as in Example 1, except that the ratio of different monomers is adjusted by adjusting the value of 1:m:n, that is, the proportion of phosphorus-nitrogen-silicon in the polymer is changed. Specific feed ratios of GMA, MAPOSS, and MAdiDOPO are shown in Table 1:

[0036]

[0037] Table 1

Embodiment 9

[0039] In a three-necked flask equipped with mechanical stirring, add 200 mg of the phosphorus-nitrogen-silicon polymer-modified graphene oxide flame retardant prepared in Example 1 above, then add acetone and ultrasonically disperse it into a black uniform dispersion. Add 7.6 g of E-51 Epoxy resin, after mixing evenly, put it in a vacuum drying oven to remove the solvent, then add 2.2g of DDM curing agent, put it into a self-made polytetrafluoroethylene mold, and put it in an oven for curing. The curing conditions are 120°C for 4 hours, and 140°C for curing 2h, followed by curing at 180°C for 2h to ensure complete curing, and then cooling to room temperature to obtain a flame-retardant epoxy resin material. The product was tested for oxygen index (LOI) according to the method of the national standard GB / T2406.1-2008, and the oxygen index of the material was measured DMA is used to study the dynamic thermomechanical properties of flame-retardant epoxy resin materials. It is mea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com