A kind of high-strength high-temperature-resistant silicone sealant and preparation method thereof

A technology of silicone sealant and high temperature resistance, applied in chemical instruments and methods, adhesives, other chemical processes, etc., can solve unfavorable product industrialization, high cost of zirconium-based ceramic powder, affecting the tensile properties of silicone sealant, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

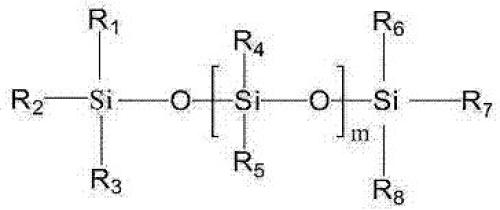

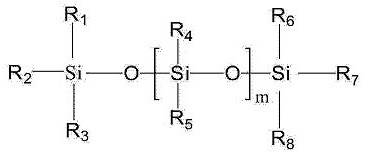

Method used

Image

Examples

Embodiment 1

[0034] a. According to the proportion by weight, 60 parts of α, ω-dipropenyloxy polydimethylsiloxane with a viscosity of 6000mPa.s, 30 parts of azidoformyloxysilane modified nano kaolin, Add 3 parts of diene-modified phenyl hydrogen-containing silicone oil into the kneader, dehydrate and blend for 15-25min at 140°C and vacuum degree of 0.06-0.099MPa, and obtain the base rubber after cooling;

[0035] b. Mix 5 parts of the mixture of methyl tributylketoxime silane: diphenyl dibutyl ketoxime silane = 2:1, diphenyl dibutyl ketoxime silane aminopropyl triethoxysilane: isocyanate group Add 1.9 parts of propyltrimethoxysilane=2:1 mixture, 0.1 part of dibutyltin dilaurate into the mixer, and stir at room temperature for 10-20 minutes to obtain the mixture;

[0036] c. Add the above-mentioned rubber base to the mixer at room temperature, stir for 15 minutes, add the above-mentioned mixture, and then react for 50 minutes at a vacuum degree of 0.08-0.099 MPa and a speed of 10-800 rpm to...

Embodiment 2

[0038] a. According to the proportion by weight, 35 parts of α, ω-dihydroxy polydimethylsiloxane with a viscosity of 90000mPa.s, 7 parts of single-ended hydroxyl polydimethylsiloxane with a viscosity of 1000mPa.s, and azide Add 50 parts of sulfonylsilane-modified nano-kaolin and 2 parts of 3-pentadecene-modified phenyl hydrogen-containing silicone oil into a kneader, and dehydrate and blend for 60 minutes at 135°C with a vacuum of 0.06-0.099MPa. After cooling, base rubber is obtained;

[0039]b. 4 parts of phenyl tributylketoxime silane: methyl vinyl dibutyl ketoxime silane = 3:1 mixture, γ-aminopropyl trimethoxysilane: isocyanate propyl triethoxysilane = 1.9 parts of a mixture of 2:2 and 0.1 part of dimethyltin dineodecanoate were added to the mixer and stirred at room temperature for 20 minutes to obtain a mixture;

[0040] c. Add the above-mentioned rubber base to the mixer at room temperature, stir for 15 minutes, add the above-mentioned mixture, and then react for 40 min...

Embodiment 3

[0042] a. According to the proportion by weight, 40 parts of α, ω-dihydroxy polydimethylsiloxane with a viscosity of 80000mPa.s, 13 parts of single-ended hydroxyl polydimethylsiloxane with a viscosity of 500mPa.s, and azide 40 parts of formamide hydrocarbyl silane modified nano-kaolin, 2 parts of 2-tridecene modified phenyl hydrogen-containing silicone oil, added to the kneader, at 145 ° C, under a vacuum of 0.06-0.099 MPa, dehydration and blending for 60 minutes, After cooling, base rubber is obtained;

[0043] b. Mix 3 parts of vinyl tributylketoxime silane: methylphenyl dibutyl ketoxime silane = 2:1 mixture, N-β aminoethyl γ-aminopropyl trimethoxysilane: isocyanate propane Add 1.95 parts of a mixture of triethoxysilane=3:1 and 0.05 parts of dimethyltin dineodecanoate into a mixer, and stir at room temperature for 20 minutes to obtain a mixture;

[0044] c. Add the above-mentioned rubber base to the mixer at room temperature, stir for 20 minutes, add the above-mentioned mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com