Synthesis method of nickel-doped iron disulfide nanowire array structure on titanium sheet substrate

A technology of nanowire array and iron disulfide, applied in chemical instruments and methods, nanotechnology, nanotechnology, etc., can solve the problems of insufficient conductivity, poor stability of hydrogen production, cumbersome preparation methods, etc., and achieve good application prospects, The gas phase reaction is simple and the synthesis method is simple and easy to implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Synthesis of In Situ FeOOH Nanowire Arrays Grown on Titanium Sheet Substrates

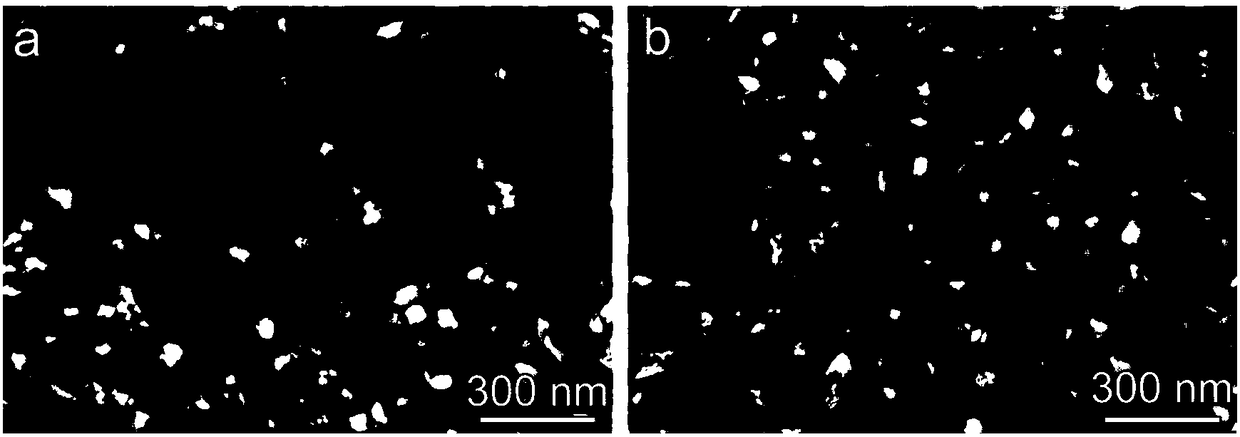

[0024] Dissolve ferric chloride hexahydrate and sodium sulfate in deionized water to obtain a reaction solution, the concentration of iron salt in the reaction solution is 25mM, the concentration of sodium sulfate is 50mM, and transfer to the reaction kettle, put into the reaction system and undergo ultrasonic treatment The cleaned bare titanium sheet was cleaned, sealed in the kettle, and placed at 120°C for 12 hours to react. After the reaction, the titanium sheet was taken out, rinsed with ethanol and deionized water in sequence, and dried at 80° C. to obtain FeOOH nanowire arrays grown in situ. The samples obtained were figure 1 As shown in (a), the scanning electron microscope shows that FeOOH is a nanowire array structure uniformly grown on the titanium substrate, and the diameter of a single nanowire is about 50-80nm.

Embodiment 2

[0026] Synthesis of Ni-FeOOH Nanowire Arrays Grown in Situ on Titanium Sheet Substrate

[0027] Ferric chloride hexahydrate, nickel dichloride hexahydrate, sodium sulfate and urea were dissolved in deionized water to obtain a reaction solution, the concentration of iron salt in the reaction solution was 25mM, the concentration of nickel salt was 25mM, and the concentration of sodium sulfate was 50mM , the concentration of urea was 50mM, and it was transferred into a reaction kettle, and a clean bare titanium sheet that had been ultrasonically treated was put into the reaction system, sealed in the kettle, and placed at 120° C. for 12 hours to react. After the reaction, the titanium sheet was taken out, rinsed with ethanol and deionized water in sequence, and dried at 80°C to obtain an in-situ grown Ni-FeOOH nanowire array. The samples obtained were figure 1 As shown in (b), the scanning electron microscope shows that Ni-FeOOH grows uniformly on the titanium substrate, and has...

Embodiment 3

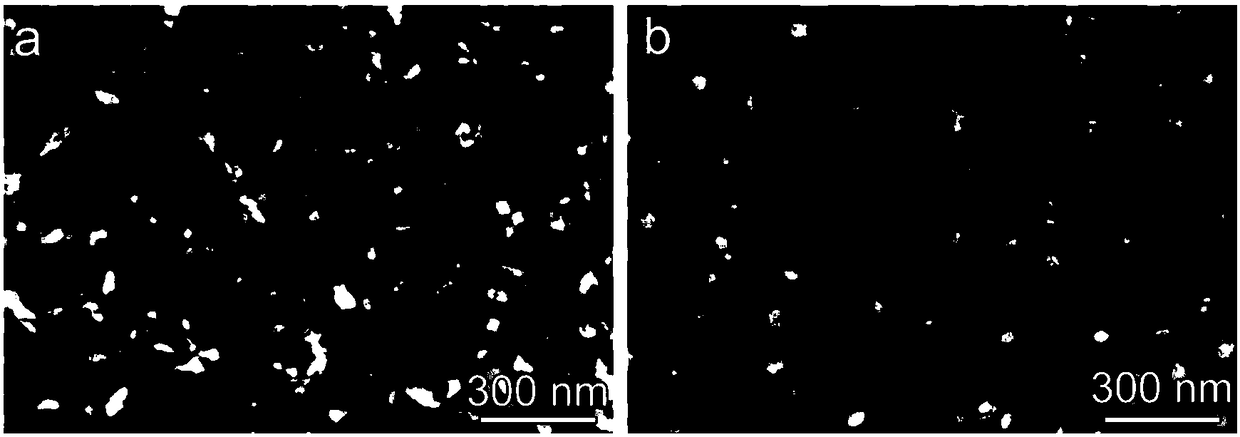

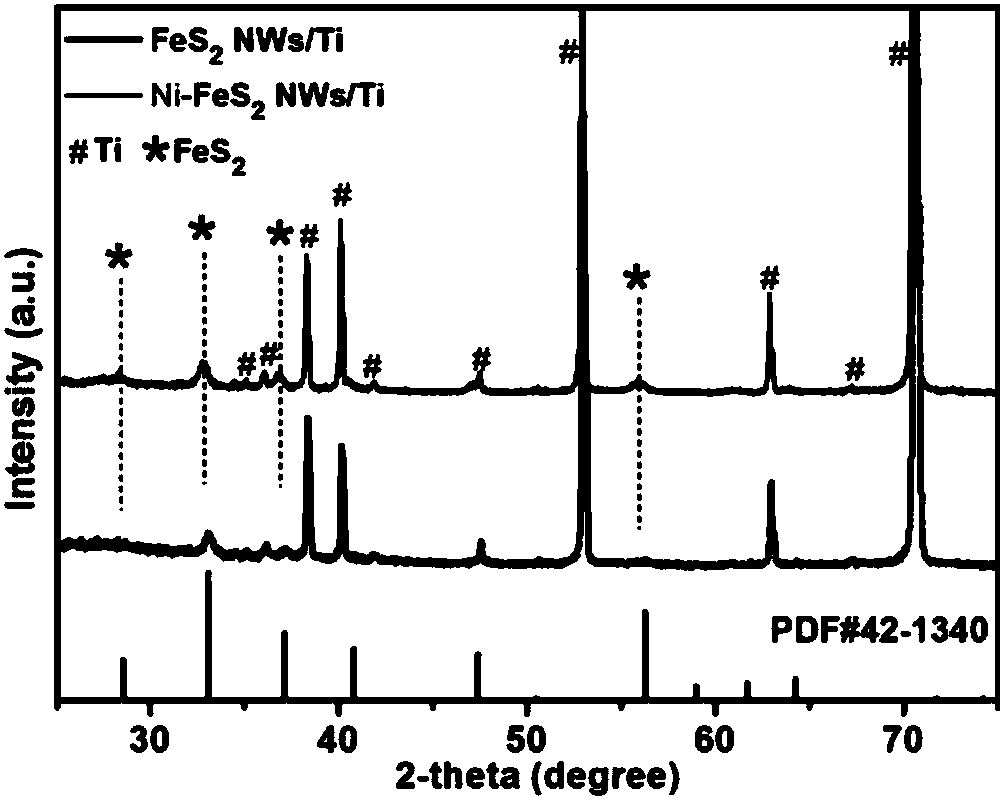

[0029] FeS on Ti substrate 2 Synthesis of nanowire array structures

[0030]Dissolve ferric chloride hexahydrate and sodium sulfate in deionized water to obtain a reaction solution, the concentration of iron salt in the reaction solution is 25mM, the concentration of sodium sulfate is 50mM, and transfer to the reaction kettle, put into the reaction system and undergo ultrasonic treatment The cleaned bare titanium sheet was cleaned, sealed in the kettle, and placed at 120°C for 12 hours to react. After the reaction, the titanium sheet was taken out, rinsed with ethanol and deionized water in sequence, and dried at 80° C. to obtain FeOOH nanowire arrays grown in situ. Then the obtained FeOOH / Ti was cut into 2cm 2 , placed in a tube furnace, and 2g of sulfur powder was weighed and placed at the gas source port of the tube furnace, and the tube furnace was repeatedly flushed with argon to exhaust the air. Under the protection of an argon atmosphere with a flow rate of 25 sccm, 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com