Tungsten disulfide/niobium disulfide heterojunction nanosheet

A technology of niobium disulfide and tungsten disulfide, which is applied in the field of catalytic materials for electrochemical hydrogen evolution, can solve the problems of high price and high energy consumption, and achieve the effects of good stability, good performance and simple synthesis steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

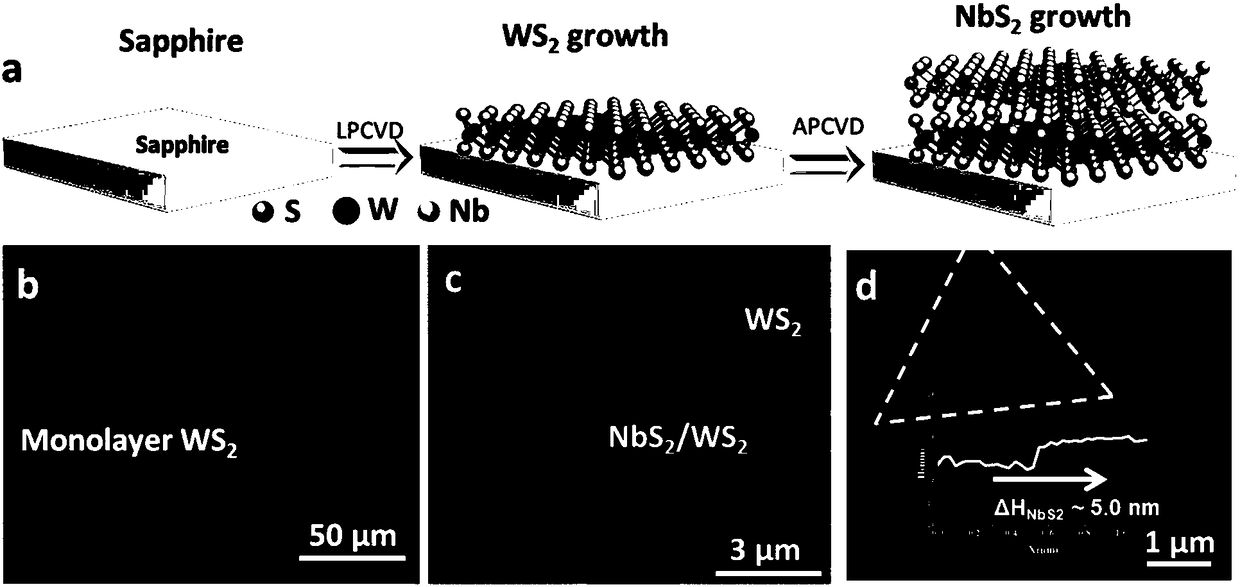

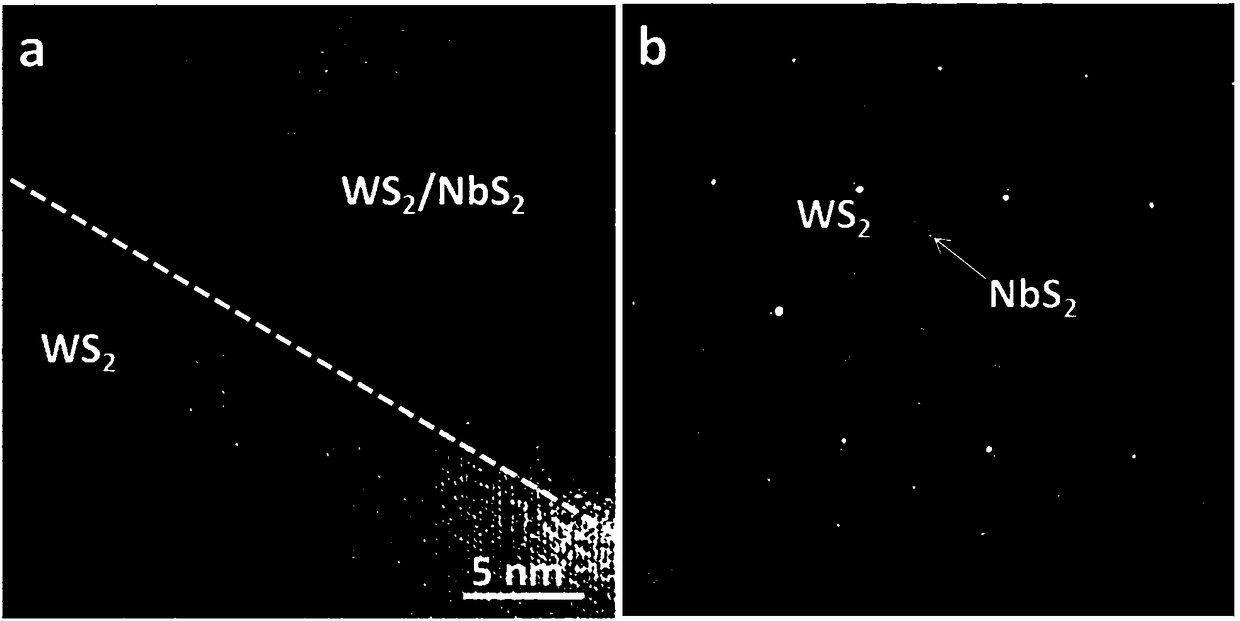

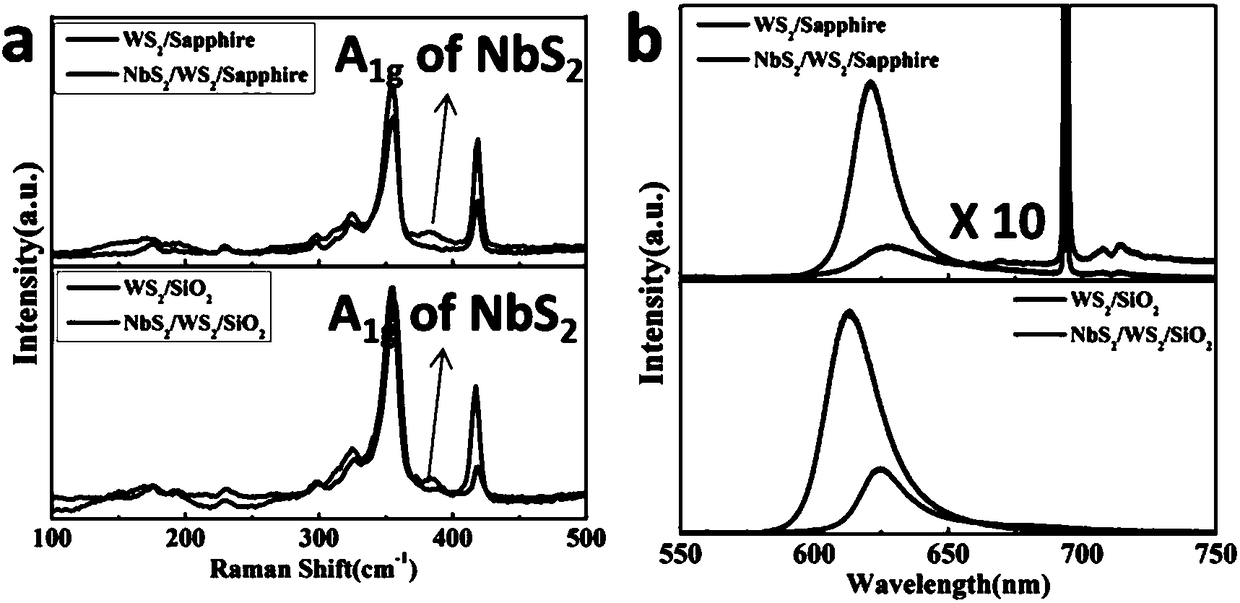

[0038] Nb 2 / WS 2 Preparation of heterojunction nanosheets (for a schematic diagram of the preparation process, see figure 1 a):

[0039](1) Using a tube furnace with three temperature zones, low-pressure chemical vapor deposition is used, sulfur powder and tungsten trioxide powder are used as reaction precursors, and sapphire single crystal is used as a growth substrate. Sulfur powder, tungsten oxide powder, and sapphire single crystal substrate were put into the quartz tube from left to right in turn. Before the reaction, the entire growth system was cleaned with a large amount of Ar gas. The flow rate of Ar gas was 500 sccm, and the gas cleaning time was 25 minutes.

[0040] Use a mechanical pump to keep the entire reaction system in a low-pressure state. The heating temperature of the sulfur powder is 100°C, the heating temperature of the tungsten oxide and the substrate are respectively 880°C, and the heating time is 35 minutes and maintained for 30 minutes. 5 sccm of ...

Embodiment 2

[0047] Nb 2 / WS 2 Preparation of heterojunction nanosheets:

[0048] (1) Using a tube furnace with three temperature zones, low-pressure chemical vapor deposition is used, sulfur powder and tungsten trioxide powder are used as reaction precursors, and sapphire single crystal is used as a growth substrate. Sulfur powder, tungsten oxide powder, and sapphire single crystal substrate were put into the quartz tube from left to right in turn. Before the reaction, the entire growth system was cleaned with a large amount of Ar gas. The flow rate of Ar gas was 500 sccm, and the gas cleaning time was 25 minutes.

[0049] Use a mechanical pump to keep the entire reaction system in a low-pressure state. The heating temperature of the sulfur powder is 100°C, the heating temperature of the tungsten oxide and the substrate are respectively 880°C, and the heating time is 35 minutes and maintained for 35 minutes. 5 sccm of hydrogen and 80 sccm of argon, cooled to room temperature after growt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com