Preparation method and application of nitrogen-doped graphene quantum dot/zinc oxide/carbon nitride composite visible light photocatalyst

A technology of graphene quantum dots and nitrogen doping, which is applied in physical/chemical process catalysts, chemical instruments and methods, hydrogen/synthesis gas production, etc. It can solve the problems of low utilization rate of visible light, low separation efficiency of photogenerated electrons and holes, etc. problem, to achieve the effect of improving photocatalytic performance, convenient separation and reuse, and wide visible light response range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1: Preparation of nitrogen-doped graphene quantum dot / zinc oxide / carbon nitride composite visible light catalyst.

[0030] To the mixture of 1.0g cyanamide, 4.5g potassium chloride and 5.5g zinc chloride, 0.25mL 5.0mg / mL nitrogen-doped graphene quantum dot dispersion was added. The above mixture was ground and mixed in a mortar and transferred to a 50 mL crucible. The crucible was calcined in a muffle furnace: the heating rate was 2.1°C / min, the temperature was raised to 520°C and kept for 6 hours, and then the temperature was naturally cooled to room temperature. Wash the solid mixture in the crucible with a large amount of hot water (60-90°C), remove all the salt, and dry it in an oven at 60°C to obtain a nitrogen-doped graphene quantum dot / zinc oxide / carbon nitride composite visible light catalyst (20% yield).

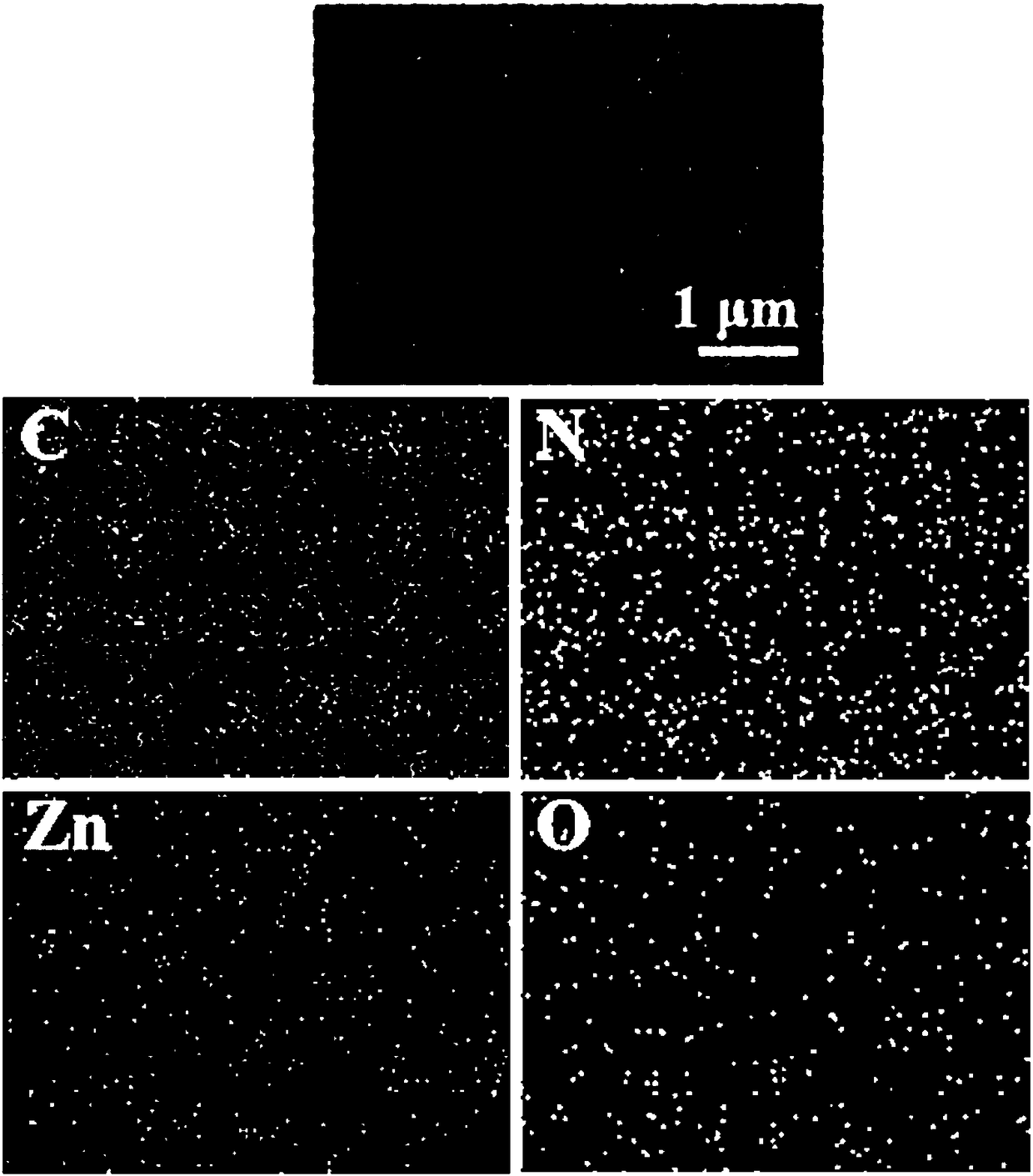

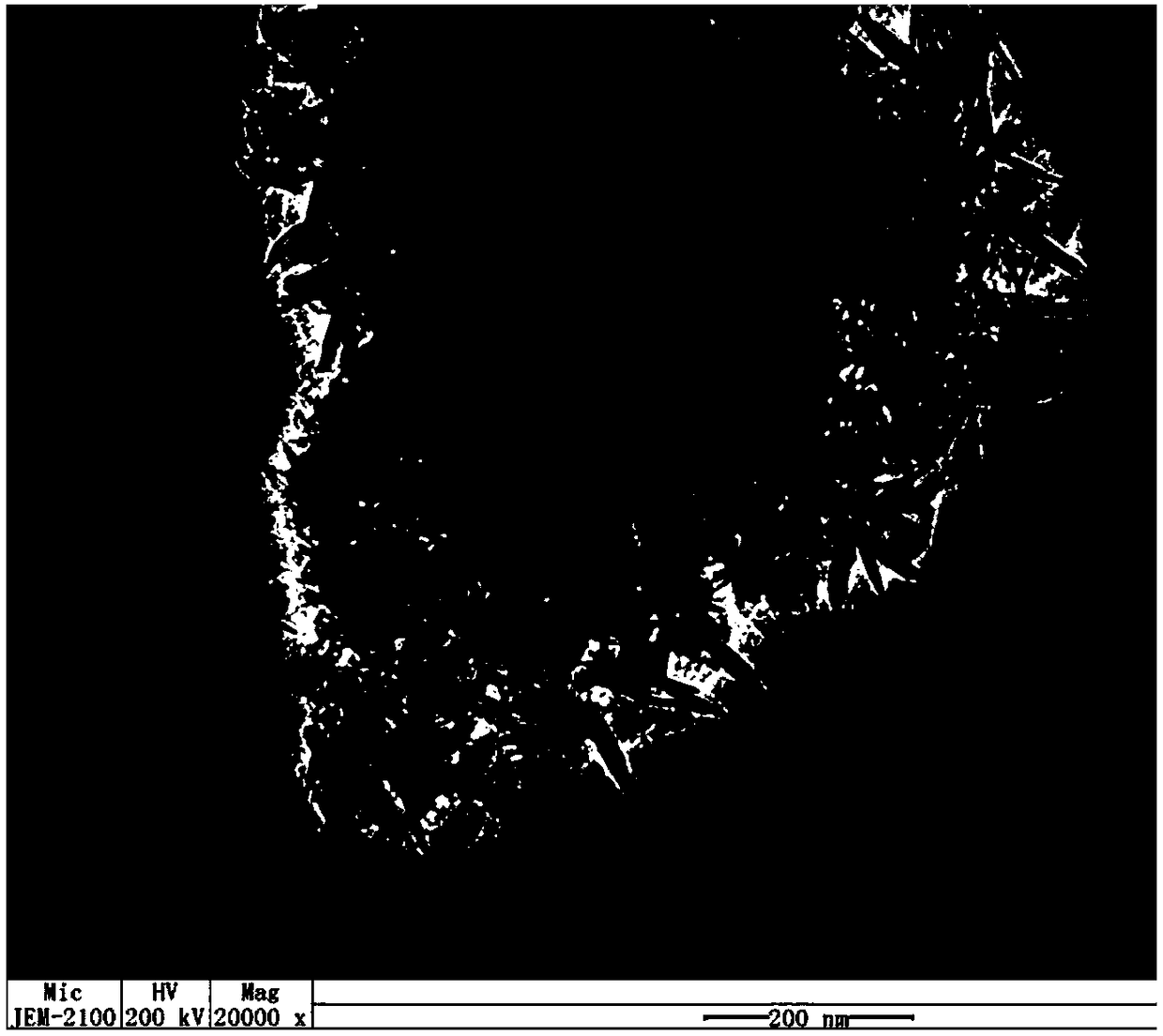

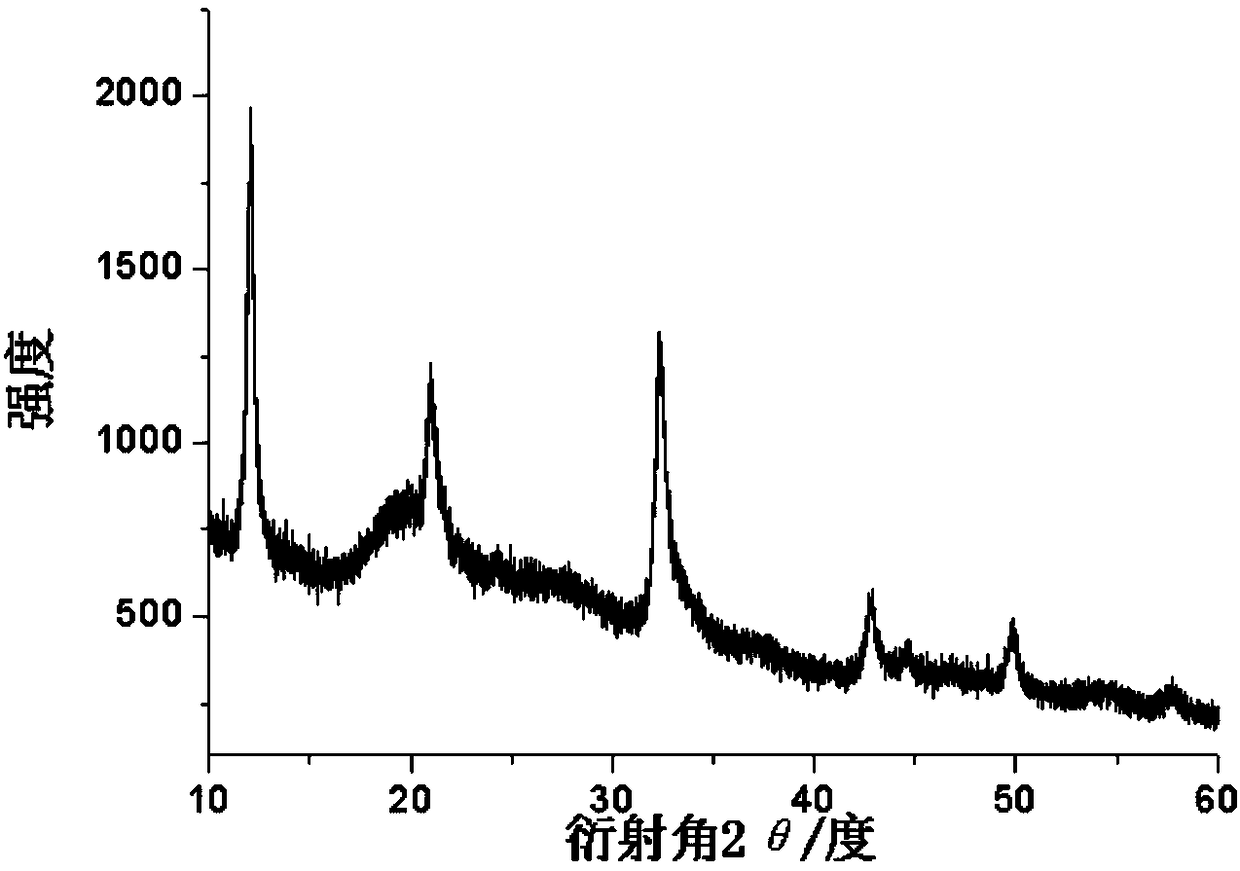

[0031] The TEM spectrogram of gained doped graphene quantum dot / zinc oxide / carbon nitride composite visible light catalyst is as follows figure 1 ...

Embodiment 2

[0032] Example 2: Nitrogen-doped graphene quantum dot / zinc oxide / carbon nitride composite visible light catalyst.

[0033] To the mixture of 1.0g cyanamide, 4.5g potassium chloride and 5.5g zinc chloride, 0.25mL 5.0mg / mL nitrogen-doped graphene quantum dot dispersion was added. The above mixture was ground and mixed in a mortar and transferred to a 50 mL crucible. The crucible was calcined in a muffle furnace: the heating rate was 2.1 °C / min, the temperature was raised to 520 °C and kept for 4 hours, and then the temperature was naturally cooled to room temperature. Wash the solid mixture in the crucible with a large amount of hot water (60-90°C), remove all the salt, and dry it in an oven at 60°C to obtain a nitrogen-doped graphene quantum dot / zinc oxide / carbon nitride composite visible light catalyst (24% yield).

Embodiment 3

[0034] Example 3: Nitrogen-doped graphene quantum dot / zinc oxide / carbon nitride composite visible light catalyst.

[0035] To the mixture of 2.0g cyanamide, 4.5g potassium chloride and 5.5g zinc chloride, 0.5mL 5.0mg / mL nitrogen-doped graphene quantum dot dispersion was added. The above mixture was ground and mixed in a mortar and transferred to a 50 mL crucible. The crucible was calcined in a muffle furnace: the heating rate was 2.1 °C / min, the temperature was raised to 520 °C and kept for 4 hours, and then the temperature was naturally cooled to room temperature. Wash the solid mixture in the crucible with a large amount of hot water (60-90°C), remove all the salt, and dry it in an oven at 60°C to obtain a nitrogen-doped graphene quantum dot / zinc oxide / carbon nitride composite visible light catalyst (32% yield).

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com