Method for preparing alumina aerogel

A technology of alumina airgel and gel, which is applied in the field of materials science, can solve the problems of high cost, large shrinkage rate, and poor blockability of alumina airgel, and achieve low-cost comprehensive performance, low shrinkage rate, and production cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

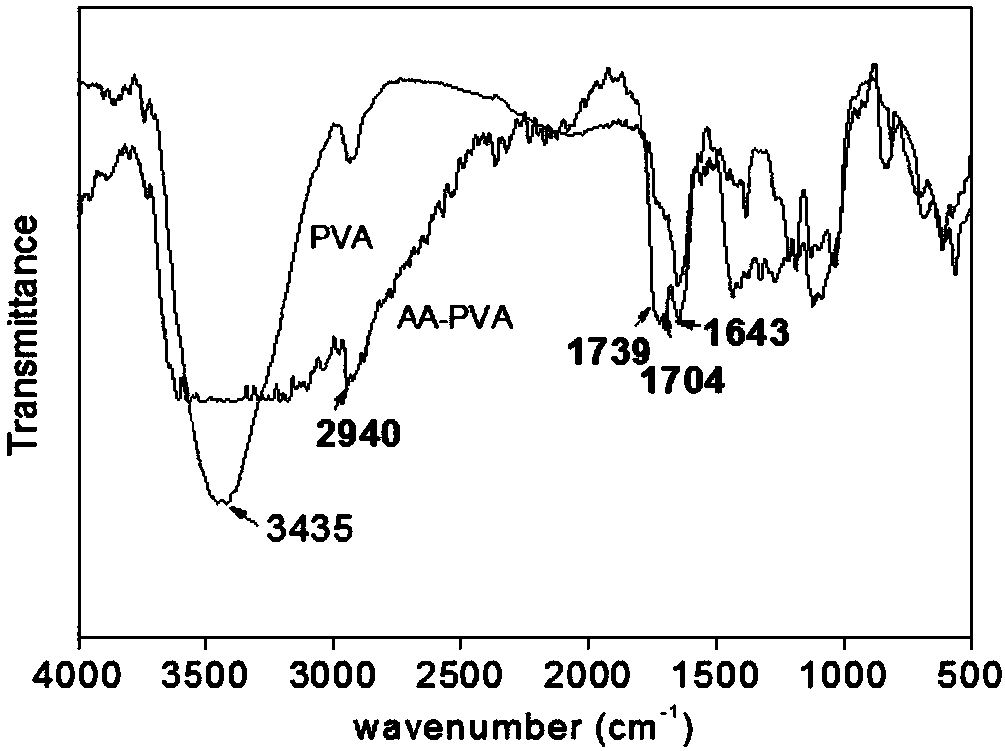

[0050] Preparation of polymer complexing agent solution: Dissolve 5g of polyvinyl alcohol in 50ml of deionized water, add sulfuric acid to adjust the pH to 1-2, heat to 85°C to dissolve completely, then add 12.5ml of methyl acetoacetate, and keep ventilation Stir in a water bath at 85°C for 5 hours, then cool the solution to room temperature, add a small amount of triethylamine to adjust the pH to 7, and this solution is a modified polyvinyl alcohol solution, which is designated as solution A.

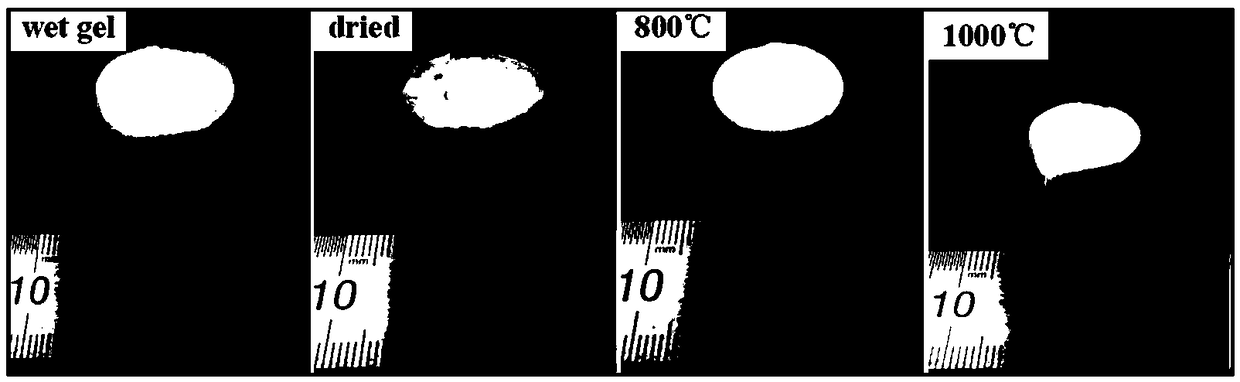

[0051] Preparation of alumina airgel: Mix solution A with deionized water, and keep the total volume at 5ml, wherein the volume ratio of solution A to deionized water is 1:4, add 1ml of absolute ethanol to the mixed solution, 0.5ml of N,N-dimethylacetamide, after stirring evenly, add 5g of aluminum chloride hexahydrate, and continue stirring for 1 hour. Add propylene oxide to the above aluminum chloride solution step by step, 2g each time, twice in total. After stirring for 2 minutes, ...

Embodiment 2

[0054] Preparation of polymer complexing agent: Dissolve 5g of polyvinyl alcohol in 50ml of deionized water, add sulfuric acid to adjust the pH to 1-2, heat to 85°C to dissolve completely, then add 12.5ml of methyl acetoacetate, and keep aeration Stir in a water bath at 85°C for 5 hours, then cool the solution to room temperature, add a small amount of triethylamine to adjust the pH to 7, and this solution is a modified polyvinyl alcohol solution, which is designated as solution A.

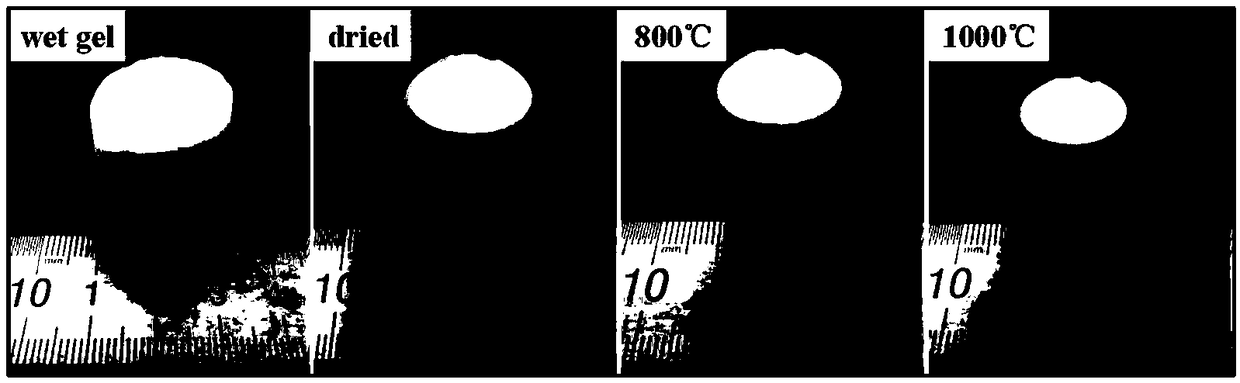

[0055] Preparation of alumina airgel: Mix solution A with deionized water, and keep the total volume at 5ml, wherein the volume ratio of solution A to deionized water is 2:3, add 1ml of absolute ethanol to the mixed solution, 0.5ml of N,N-dimethylacetamide, after stirring evenly, add 5g of aluminum chloride hexahydrate, and continue stirring for 1 hour. Add propylene oxide to the above aluminum chloride solution step by step, 2g each time, twice in total. After stirring for 2 minutes, take out the...

Embodiment 3

[0058] Preparation of polymer complexing agent: Dissolve 5g of polyvinyl alcohol in 50ml of deionized water, add sulfuric acid to adjust the pH to 1-2, heat to 85°C to dissolve completely, then add 12.5ml of methyl acetoacetate, and keep aeration Stir in a water bath at 85°C for 5 hours, then cool the solution to room temperature, add a small amount of triethylamine to adjust the pH to 7, and this solution is a modified polyvinyl alcohol solution, which is designated as solution A.

[0059] Preparation of alumina airgel: Mix solution A with deionized water, and keep the total volume at 5ml, wherein the volume ratio of solution A to deionized water is 3:2, add 1ml of absolute ethanol to the mixed solution, 0.5ml of N,N-dimethylacetamide, after stirring evenly, add 5g of aluminum chloride hexahydrate, and continue stirring for 1 hour. Add propylene oxide dropwise to the above aluminum chloride solution, 2 g each time, twice in total. After stirring for 2 minutes, take out the ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface | aaaaa | aaaaa |

| Specific surface | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com