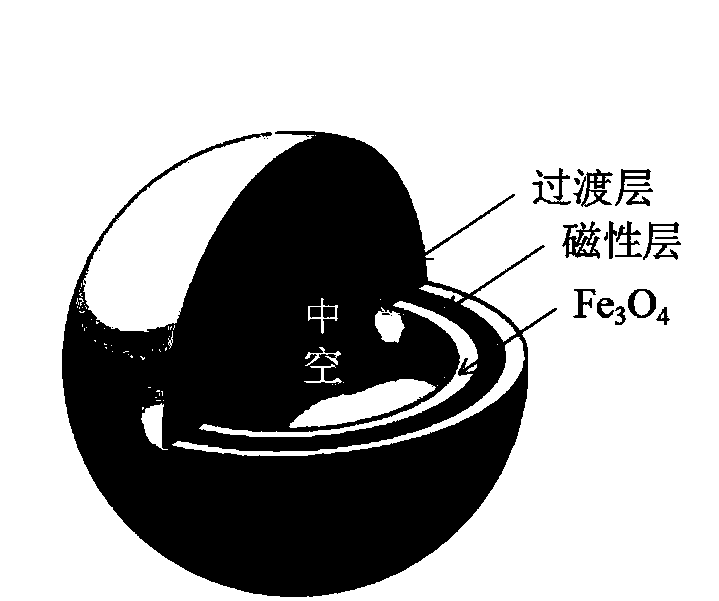

Preparation method of yolk type double-shell-layer hollow composite wave absorption material

A composite wave-absorbing material and double-shell technology, applied in metal material coating process, coating, liquid chemical plating, etc., can solve the problem that the electromagnetic parameters are difficult to meet the relative permittivity and relative permeability Thin thickness, light weight and other problems, to achieve the effect of reducing quality, easy operation, and broadening the wave-absorbing frequency band

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] A method for preparing an egg yolk-shaped double-shell hollow composite wave-absorbing material, comprising the following steps:

[0030] (1) First add iron salt into the solvent, ultrasonically dissolve it completely, then add alkali, continue ultrasonically disperse to make it evenly dispersed, then transfer the above mixed solution to a high-temperature reaction kettle, react at a certain temperature for a certain period of time, and finally Separation by magnetic decantation and washing with absolute ethanol, the product can be obtained after vacuum drying 3 o 4 Nanoparticles.

[0031] Iron salt can be FeCl in described step (1) 3 ·6H 2 O, Fe 2 (SO 4 ) 3 9H 2 O, Fe(NO 3 ) 3 9H 2 O, FeCl 2 4H 2 O, FeSO 4 ·7H 2 O, Fe(NO 3 ) 2 ·6H 2 O et al.

[0032] The solvent may be deionized water, alcohols (methanol, ethanol, ethylene glycol, glycerol, etc.), ketones (acetone, methyl ethyl ketone, etc.) and the like.

[0033] The base may be ammonia water, ethyl...

Embodiment 1

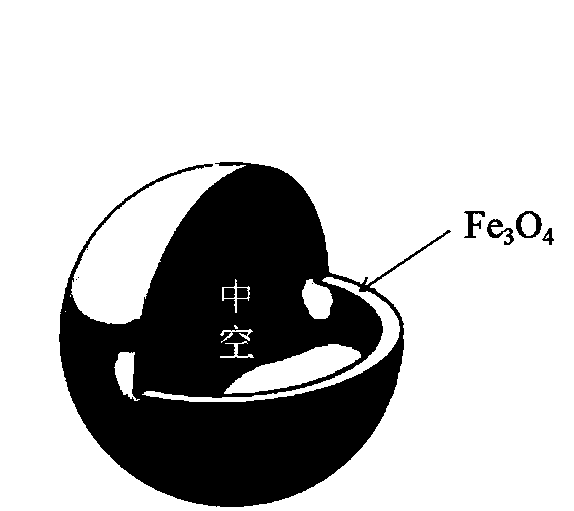

[0041] (1) First, 2.703g FeCl 3 ·6H 2 O was added to 60mL of ethylene glycol, sonicated for 15min to completely dissolve it, then 4mL of ethylenediamine was added, and the ultrasonic dispersion was continued for 30min to disperse evenly, then the above mixed solution was transferred to a high-temperature reactor, and reacted at 200°C for 12h , and finally separated by magnetic decantation and washed with absolute ethanol, the product can be obtained after vacuum drying 3 o 4 Nanoparticles, see figure 1 , hollow Fe 3 o 4 The nanoparticles have a particle size of about 400 nm and a wall thickness of about 100 nm.

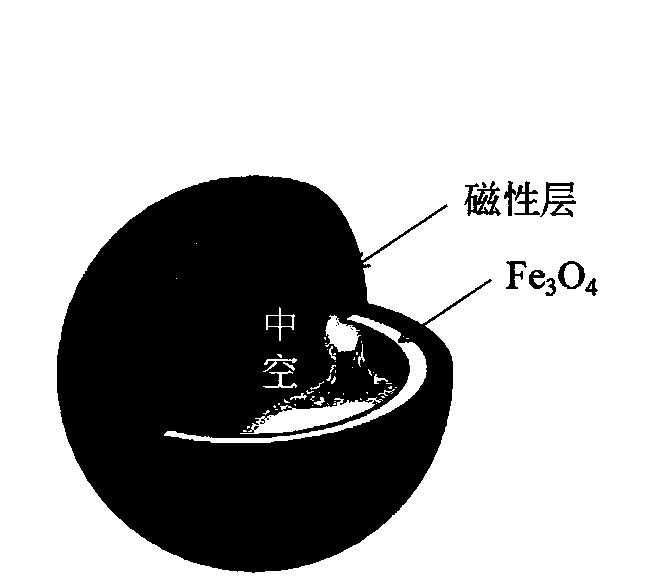

[0042] (2) take by weighing the hollow Fe obtained in 0.5g step (1) 3 o 4 Nanoparticles were dispersed in 150 mL of deionized water, and 20 mmol of ferrous chloride tetrahydrate (FeCl 2 4H 2 O), 20mmol of cobalt chloride hexahydrate (CoCl 2 ·6H 2 (2) and 0.3mol of trisodium citrate as solution A; in addition, 40mL of 50% hydrazine hydrate and 2mol of sodium...

Embodiment 2

[0047] (1) First, 2.809g Fe 2 (SO 4 ) 3 9H 2 O was added to 60mL of deionized water, sonicated for 15min to dissolve completely, followed by adding 4mL of ethylenediamine, and continued to disperse ultrasonically for 30min to disperse evenly, then transferred the above mixed solution to a high-temperature reactor, and reacted at 200°C for 12h. Finally, it is separated by magnetic decantation and washed with absolute ethanol, and the product can be obtained after vacuum drying. 3 o 4 Nanoparticles (particle size about 500nm, wall thickness about 100nm).

[0048] (2) Take by weighing the hollow Fe obtained in 0.1g step (1) 3 o 4 Nanoparticles were dispersed in 150mL deionized water, and 12mmol of FeCl was added 2 4H 2 O, 28mmol of CoCl 2 ·6H 2 O and 0.3mol of trisodium citrate, as solution A; another 40mL of 50% hydrazine hydrate and 2mol of sodium hydroxide were dispersed in 90mL of deionized water, as solution B; solution B was added dropwise to solution A while stir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com