Quasi-solid electrolyte for dye-sensitized solar cell

A technology of solar cells and dye sensitization, which is applied in the field of new materials and new energy sources, can solve the problems affecting the photoelectric conversion efficiency of dye-sensitized solar cells, the low conductivity of monoimidazole-type ion crystals, and the inevitable volatilization of ethylene carbonate, etc., to achieve Improve photoelectric conversion efficiency, enhance electrical conductivity, and avoid leakage problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

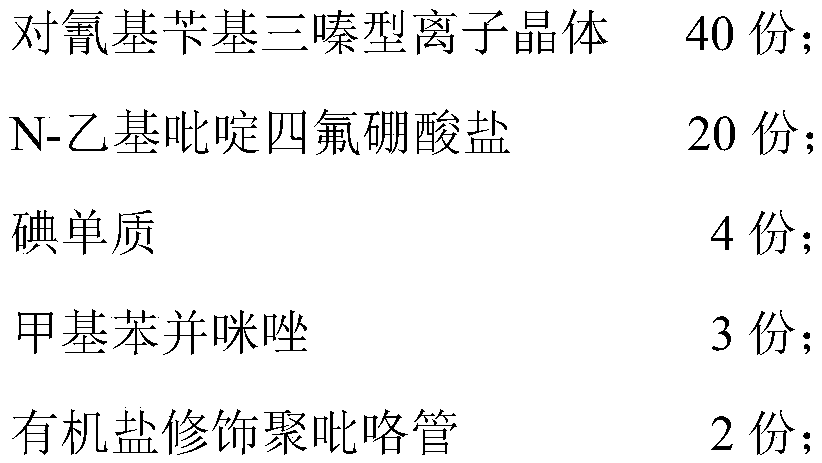

Embodiment 1

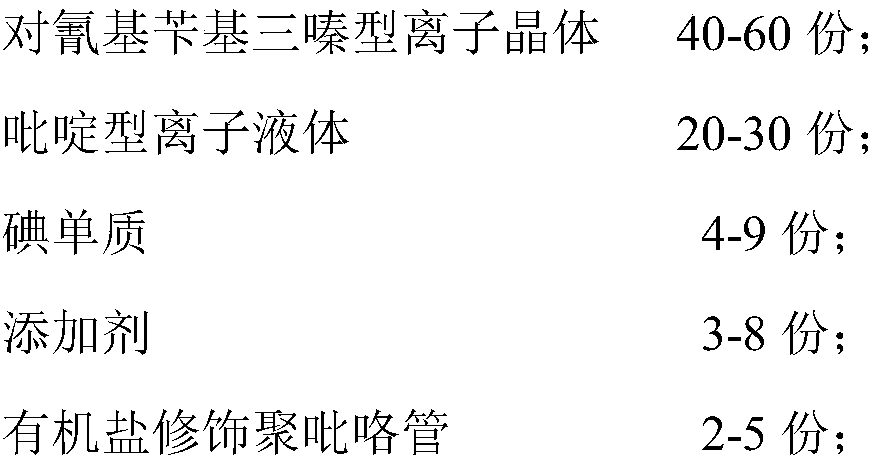

[0030] A quasi-solid electrolyte for a dye-sensitized solar cell is composed of the following components, and the content of each component is expressed in parts by weight:

[0031]

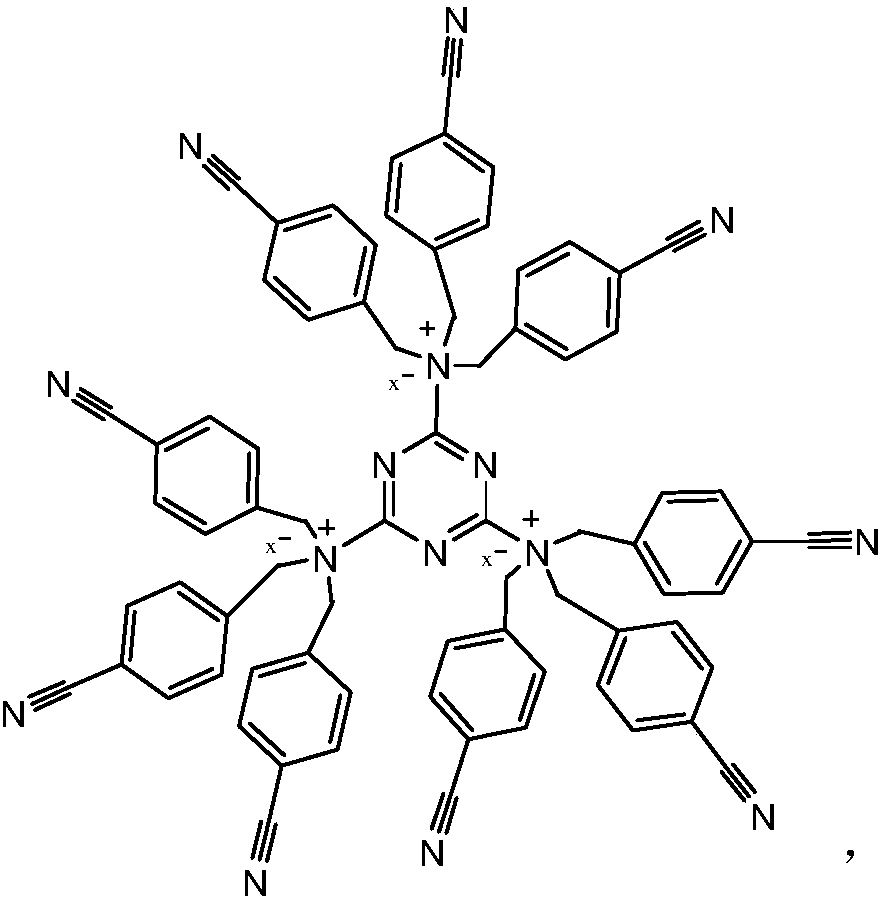

[0032] Wherein, the general chemical structure formula of the p-cyanobenzyl triazine type ionic crystal is:

[0033]

[0034] The preparation method of the p-cyanobenzyltriazine-type ionic crystals comprises the following steps: adding 10 g of melamine into 150 g of ether, and adding 140 g of p-cyanobenzyl bromide therein, stirring and reacting at 40° C. for 6 hours, and then The product was washed 5 times with ether, and then the solvent was removed by rotary evaporation at 50°C.

[0035] The preparation method of the polypyrrole tube modified by the organic salt comprises the following steps: dispersing 30 g of the polypyrrole tube in 100 g of dimethyl sulfoxide, adding 10 g of 3-chloroallyl hexamethylenetetramine to it, and oxidizing Sodium 10g, heated to 40°C and reacted for 15 hours. ...

Embodiment 2

[0037] A quasi-solid electrolyte for a dye-sensitized solar cell is composed of the following components, and the content of each component is expressed in parts by weight:

[0038]

[0039]

[0040] Wherein, the general chemical structure formula of the p-cyanobenzyl triazine type ionic crystal is:

[0041]

[0042] The preparation method of the p-cyanobenzyltriazine-type ionic crystals comprises the following steps: adding 10 g of melamine into 170 g of ethyl acetate, and adding 140 g of p-cyanobenzyl chloride therein, stirring and reacting at 43° C. for 6.5 hours, Finally, the product was washed with ether for 6 times, and then the solvent was removed by rotary evaporation at 52°C;

[0043] The preparation method of the organic salt modified polypyrrole tube comprises the following steps: dispersing 35 g of the polypyrrole tube in 120 g of N,N-dimethylformamide, and then adding 3-chloroallyl hexamethylenetetra 13 g of amine and 10 g of potassium tert-butyl alkoxid...

Embodiment 3

[0045] A quasi-solid electrolyte for a dye-sensitized solar cell is composed of the following components, and the content of each component is expressed in parts by weight:

[0046]

[0047] Wherein, the general chemical structure formula of the p-cyanobenzyl triazine type ionic crystal is:

[0048]

[0049] The preparation method of the p-cyanobenzyltriazine-type ionic crystals comprises the following steps: adding 10 g of melamine into 200 g of acetone, and adding 140 g of p-cyanobenzyl bromide therein, stirring and reacting at 46° C. for 7 hours, and then Wash the product 7 times with ether, and then remove the solvent by rotary evaporation at 57°C; then soak the product in 100 g of an aqueous solution of 20% sodium tetrafluoroborate at 40°C for 20 hours, and then remove the water by rotary evaporation at 95°C , and then dissolved in dichloromethane, filtered, and the solvent was removed by rotary evaporation at 35°C.

[0050]The preparation method of the organic sal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com