Nickel nitride nanometer composite electrocatalytic material, and preparation method and application thereof

An electrocatalytic material and nanocomposite technology, applied in the field of catalysis, can solve problems such as limiting catalyst performance and hindering electron transfer, and achieve the effects of improving electron transfer efficiency, reducing consumption, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

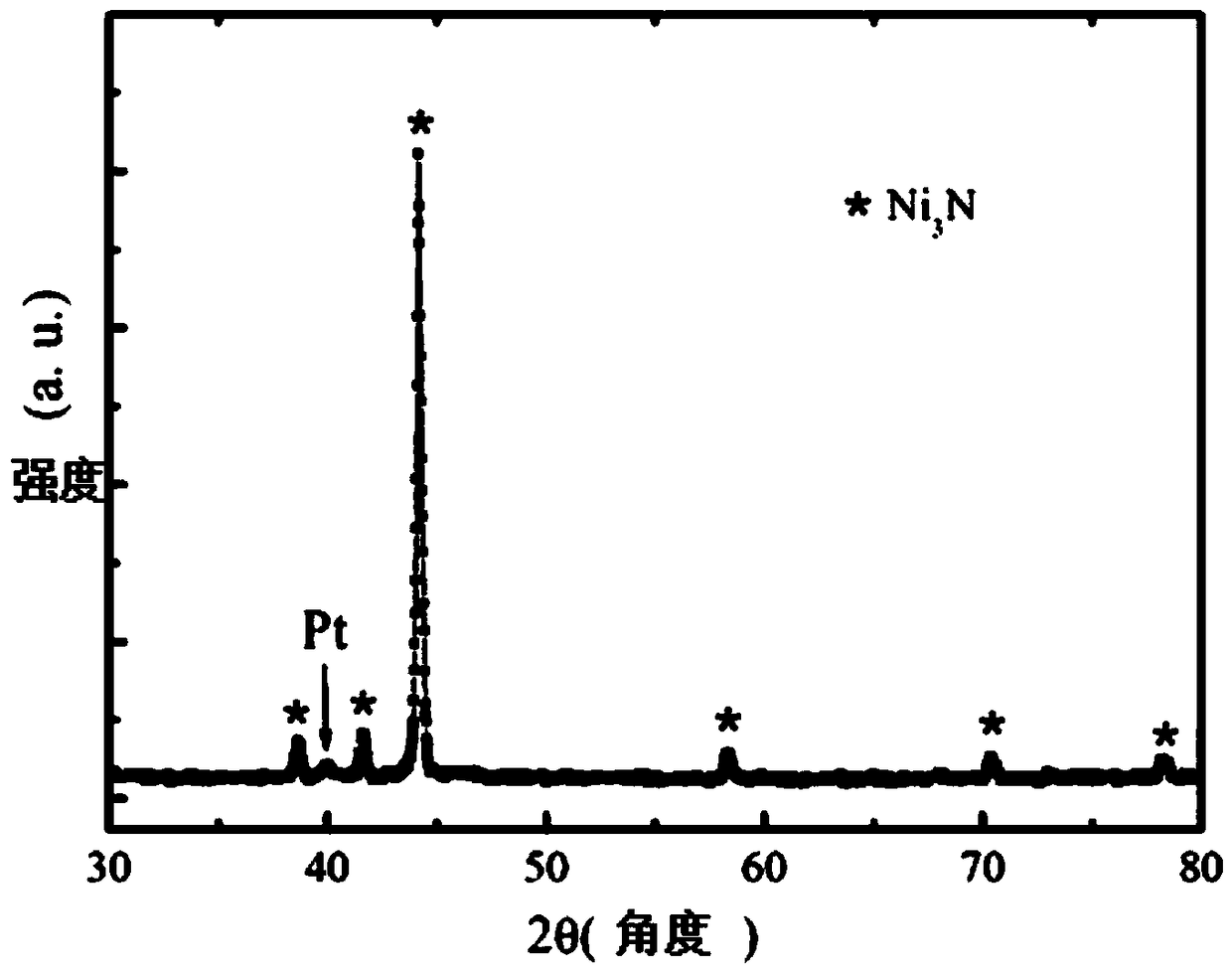

[0027] Ni 3 The preparation method of N / Pt nanocomposite catalytic material, the steps are as follows:

[0028] 1. Weigh 2.1g of nickel sulfate hexahydrate, 0.32g of sodium hydroxide and 0.24g of urea in a molar ratio of 2:2:1, add them to 25mL of absolute ethanol, and stir thoroughly to obtain a uniformly mixed solution;

[0029] 2. Put the mixed solution into the reaction kettle and react at 170°C for 24 hours;

[0030] 3. After the reaction was completed, the reaction product was ultrasonically washed 5 times with distilled water and absolute ethanol respectively, put into a drying oven, and dried at a constant temperature of 80°C for 6 hours.

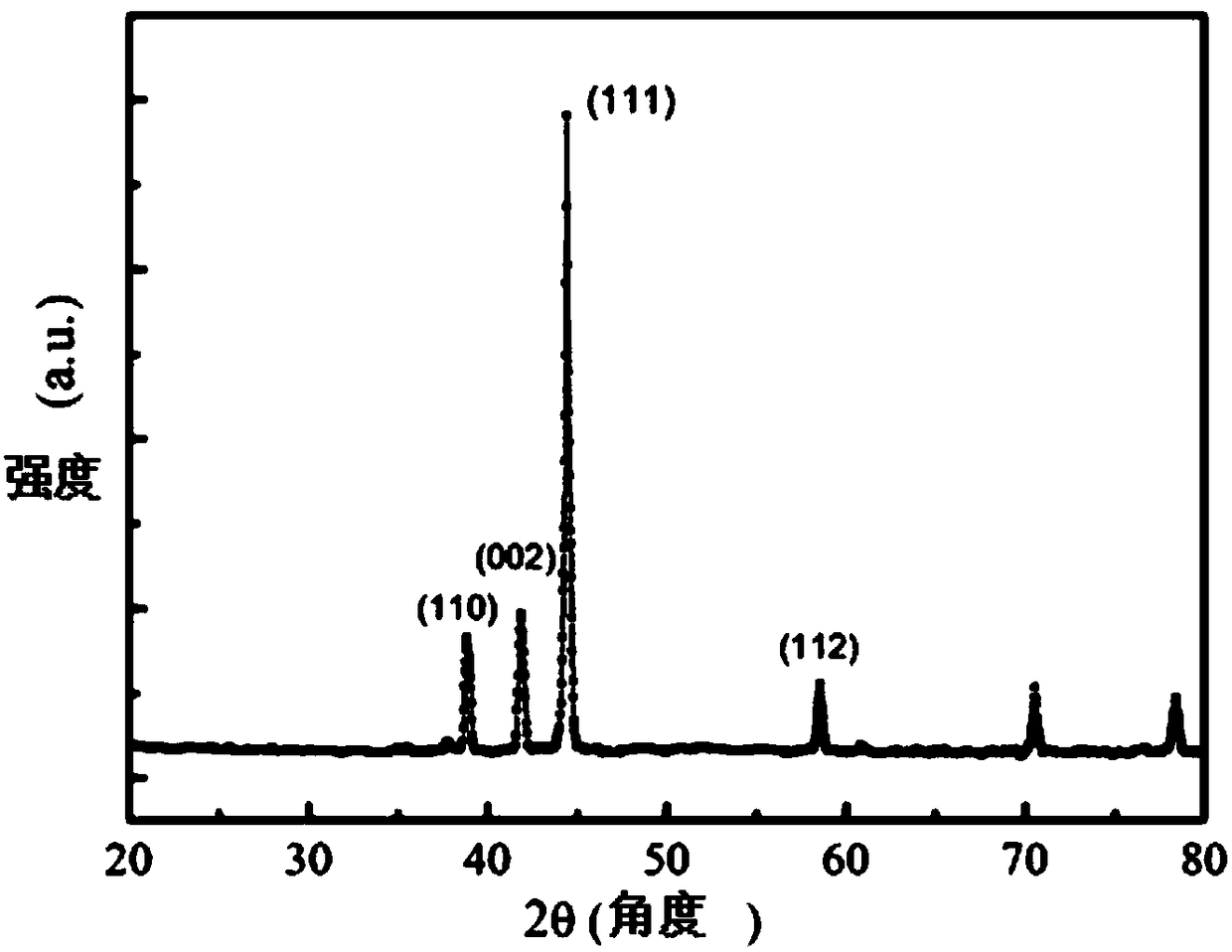

[0031] 4. Press the obtained powder sample into tablets and put it into a vacuum tube furnace for roasting with a vacuum degree of 5×10 -4Pa, raise the temperature to 450°C, keep the temperature for 2h, and obtain the nickel nitride sample after natural cooling.

[0032] 5. Platinum nanoparticles were deposited on the surface of ...

Embodiment 2

[0034] Ni 3 The preparation method of N / Pt nanocomposite catalytic material, the steps are as follows:

[0035] 1. Weigh 1.9016g of nickel chloride hexahydrate, 0.32g of sodium hydroxide and 0.24g of urea in a molar ratio of 2:2:1, add them to 25mL of absolute ethanol, and stir thoroughly to obtain a uniformly mixed solution;

[0036] 2. Put the mixed solution into the reaction kettle and react at 150°C for 30 hours;

[0037] 3. After the reaction is completed, the reaction product is ultrasonically washed 4 times with distilled water and absolute ethanol respectively, put into a drying oven, and dried at a constant temperature of 60°C for 8 hours.

[0038] 4. Press the obtained powder sample into tablets and put it into a vacuum tube furnace for roasting with a vacuum degree of 3×10 -4 Pa, raise the temperature to 400°C, keep the temperature for 3h, and obtain the nickel nitride sample after natural cooling.

[0039] 5. Platinum nanoparticles were deposited on the surface ...

Embodiment 3

[0041] Ni 3 The preparation method of N / Pt nanocomposite catalytic material, the steps are as follows:

[0042] 1. Weigh 2.1g of nickel sulfate hexahydrate, 0.45g of potassium hydroxide and 0.24g of urea in a molar ratio of 2:2:1, add them to 25mL of absolute ethanol, and stir thoroughly to obtain a uniformly mixed solution;

[0043] 2. Put the mixed solution into the reaction kettle and react at 200°C for 20 hours;

[0044] 3. After the reaction was completed, the reaction product was ultrasonically washed 6 times with distilled water and absolute ethanol, respectively, put into a drying oven, and dried at a constant temperature of 100°C for 5 hours.

[0045] 4. Press the obtained powder sample into tablets and put it into a vacuum tube furnace for roasting with a vacuum degree of 7×10 -4 Pa, raise the temperature to 500°C, keep the temperature for 3h, and obtain the nickel nitride sample after natural cooling.

[0046] 5. Platinum nanoparticles were deposited on the surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com