A strain of Lactobacillus johnsonii with high ferulic acid esterase production and its application

A technology of Lactobacillus johnsonii and ferulic acid esterase, applied in the direction of application, enzymes, bacteria, etc., can solve the problems of constraints and expensive ferulic acid esterase, so as to improve palatability, promote sustainable agricultural development, fast growing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Embodiment 1, the isolation and identification of HCOM3 bacterial strain

[0049] 1. Isolation of HCOM3 strain

[0050]HCOM3 was isolated from the colon of 1.5-month-old healthy piglets. The specific separation method is as follows: take the contents of the colon of healthy piglets at the age of one and a half months after dissection, and divide it with normal saline according to 10 -1 to 10 -7 Carry out gradient dilution, select the appropriate gradient and spread it on 1L MRS medium (the formula of 1L MRS medium is beef extract 10g, casein peptone 10g, yeast extract 5g, glucose 20g, sodium acetate 5g, diamine hydrogen citrate 2g, Tween80 1 mL, K 2 HPO 4 2g, MgSO 4 ·7H 2 O 0.58g, MnSO 4 ·7H 2 (0.25g, agar powder 1.5%, distilled water to 1L, autoclaved) or improved MC medium (1L improved MC medium formula is soybean peptone 5g, beef extract powder 3g, yeast extract powder 3g, Glucose 20g, lactose 20g, calcium carbonate 10g, agar powder 1.5%, distilled water to ...

Embodiment 2

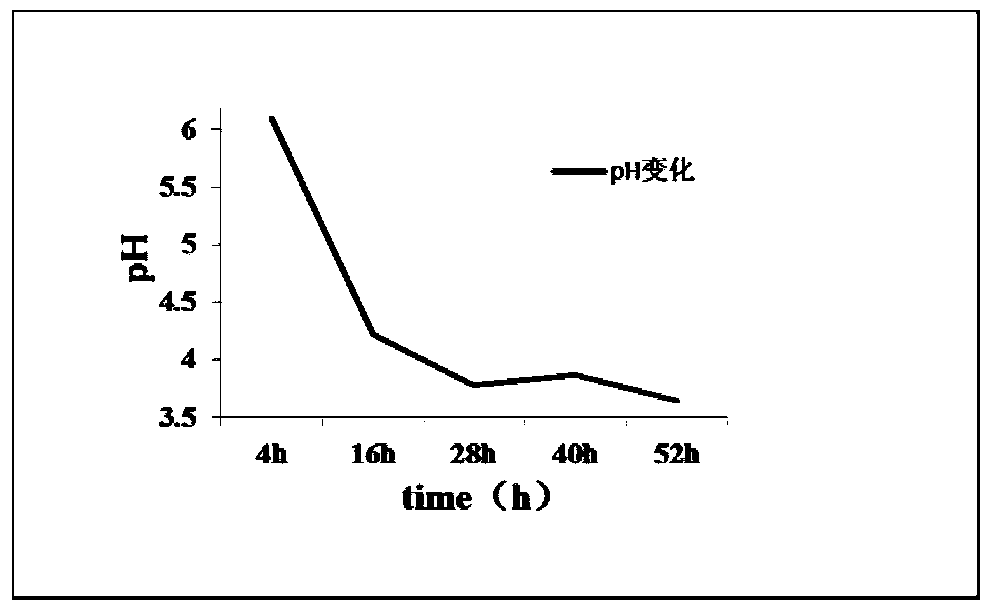

[0055] Example 2, the detection of the acid production rate of the HCOM3 bacterial strain

[0056] The HCOM3 strain isolated and purified in Example 1 was inoculated into the MRS liquid medium, and fermented and cultured in a 37°C incubator for 4h, 16h, 28h, 40h or 52h, and samples were taken at each time period to detect the pH value of the fermentation broth. The fermentation time is plotted on the abscissa, and the pH value of the fermented liquid is plotted on the ordinate to draw a change curve.

[0057] The result is as figure 1 as shown ( figure 1 It is the curve graph of the HCOM3 strain cultured in MRS medium at 37°C for 52h). It can be seen from the figure that the HCOM3 bacterial strain of the present invention produces fast acid, grows fast, and has good growth performance.

Embodiment 3

[0058] Embodiment 3, the preparation of microbial preparation HCOM3

[0059] 1. Inoculate the HCOM3 strain isolated and purified in Example 1 into MRS liquid medium, and ferment and cultivate in a 37°C incubator for 24 hours to obtain HCOM3 fermentation broth;

[0060] 2. The HCOM3 fermentation broth was centrifuged at 10000-12000rpm for 2-5min, and the supernatant was collected to obtain the HCOM3 fermentation broth supernatant (the HCOM3 bacterial strain concentration was 10 14 -10 18 CFU / L). The HCOM3 fermentation broth supernatant was named microbial preparation HCOM3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com