Preparation method of mussel-imitated contact antibacterial hydrogel for tissue repair

A tissue repair and hydrogel technology, applied in medical science, surgery, etc., can solve problems such as bacterial resistance, failure of biomedical material implantation, unfavorable cell adhesion, etc., to increase tissue affinity, excellent reliability, etc. Restorative, enhanced antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] A method for preparing a mussel-like contact antibacterial hydrogel for tissue repair includes the following steps:

[0026] Step 1: Prepare mixed solution A of quaternary ammonium salt-modified natural polymer and methacrylamidated dopamine. The concentration of quaternary ammonium salt-modified natural polymer in mixed solution A is 1wt.%~8wt.%, methacrylamidated The dopamine concentration is 0.1wt.% ~1wt.%;

[0027] Step 2: Add anionic monomer and cationic monomer with a mass ratio of 9:1~7:3 to mixed solution A to form mixed solution B; the total concentration of anionic monomer and cationic monomer in mixed aqueous solution B is 5wt.% ~30wt.%;

[0028] Step 3: Add initiator and cross-linking agent to the mixed aqueous solution B, and a polymerization reaction occurs. After the reaction is completed, the desired hydrogel is formed.

[0029] Further, in the step 3, the polymerization reaction is carried out at a temperature of 60° C. and airtight conditions for 5-20 minutes...

Embodiment 1

[0038] The preparation method of the imitation mussel contact antibacterial hydrogel for tissue repair is as follows:

[0039] Weigh 0.1g of quaternized chitosan and dissolve in 10ml of deionized water, stir thoroughly to form a transparent solution; weigh 0.015g of methacrylamidated dopamine and dissolve in the quaternized chitosan solution to form a mixed solution A ; Then weigh 1.75g anionic monomer acrylic acid, 0.75g cationic monomer dimethylaminoethyl methacrylate, 0.08g sodium persulfate and 0.003g N, N-methylene bisacrylamide into the mixed solution A and stir uniformly to form Mixed solution B: Pour the mixed solution B into a closed mold, and react for 5 minutes at 60° C. to polymerize to form a hydrogel.

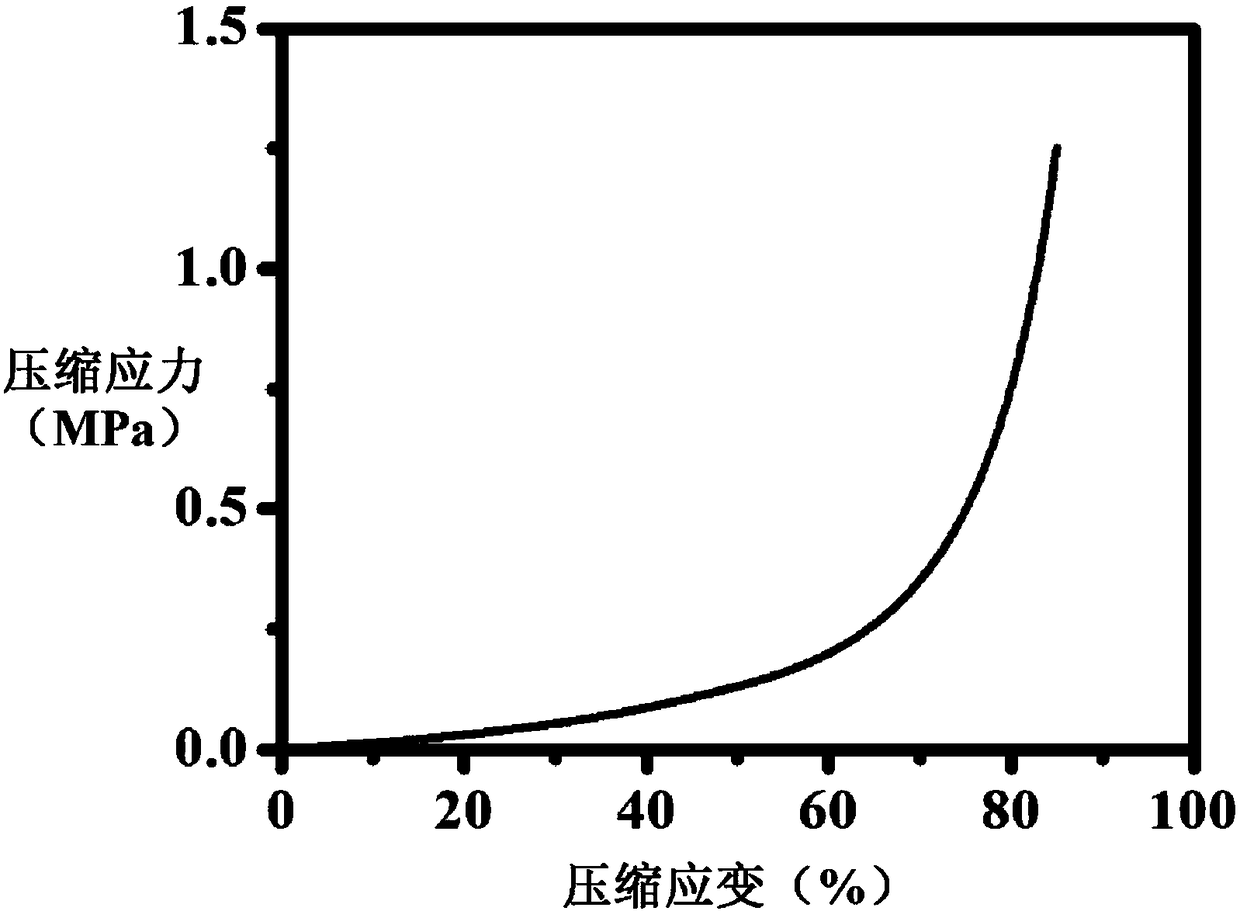

[0040] The hydrogel prepared according to the above method is subjected to compression test, figure 1 It can be seen from the figure that when the compressive strain reaches 85%, the hydrogel does not break and the compressive strength reaches 1.25MPa; the hydrogel i...

Embodiment 2

[0044] The preparation method of the imitation mussel contact antibacterial hydrogel for tissue repair is as follows:

[0045] Weigh 0.7g of quaternized chitosan and dissolve in 10ml of deionized water, stir thoroughly to form a transparent solution; weigh 0.075g of methacrylamidated dopamine and dissolve in the quaternized chitosan solution to form a mixed solution A ; Then weigh 1.75g anionic monomer acrylic acid, 0.75g cationic monomer dimethylaminoethyl methacrylate, 0.08g sodium persulfate and 0.003g N, N-methylene bisacrylamide into the mixed solution A and stir uniformly to form Mixed solution B: Pour mixed solution B into a closed mold and place it at 60°C for 15 minutes to polymerize to form a hydrogel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com