Preparation method of anti-corrosion, antifouling and anti-protein waterborne polyurea grafted graphene coating material

A technology of grafted graphite and coating materials, applied in antifouling/underwater coatings, anti-corrosion coatings, polyurea/polyurethane coatings, etc., can solve the problems of increasing ship weight, energy waste, and damaging metal surface coatings, etc., to achieve Effects of prevention of marine fouling adhesion, excellent mechanical properties, and efficient preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for preparing an anti-corrosion, anti-fouling and anti-protein unit water-based polyurea grafted graphene coating material is carried out according to the following steps:

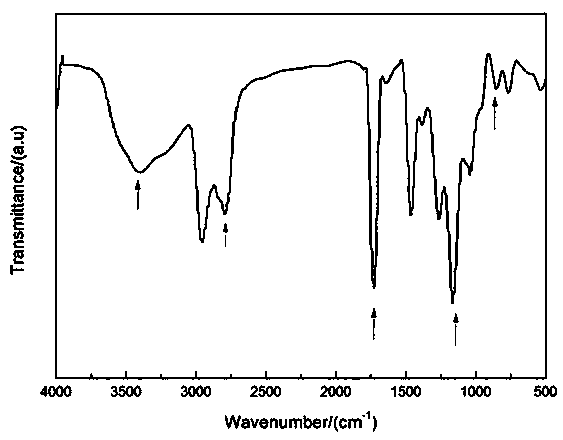

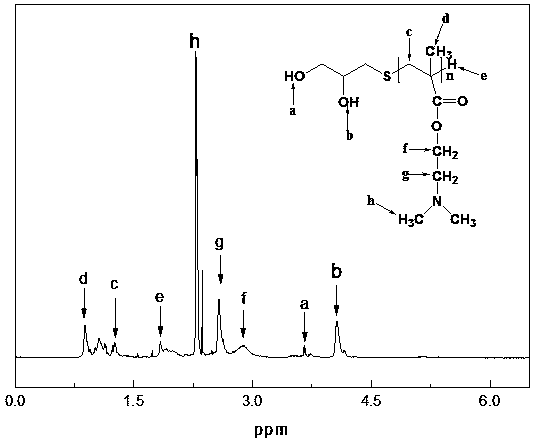

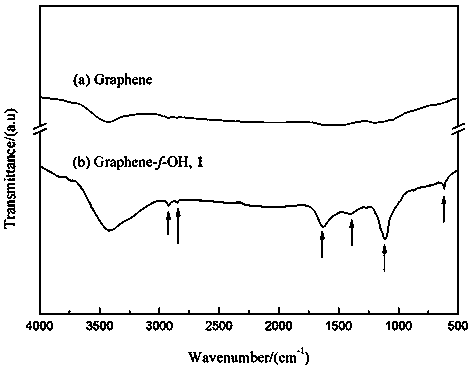

[0029] (1) Antiprotein unit: Add 7.85g of dimethylaminoethyl methacrylate, 1.109g of mercaptopropylene glycol, 0.0785g of azobisisobutyronitrile purified from absolute ethanol and 20 mL of tetrahydrofuran into a 100 mL single-necked flask, and Stir the reaction at 70°C under the protection of nitrogen for 12 h, cool with liquid nitrogen to terminate the reaction, remove tetrahydrofuran with a rotary evaporator, add an appropriate amount of n-hexane dropwise, stir well, centrifuge twice at 4000 r / min for 5 min, and place the product at 45°C Vacuum-dry for 12 h for later use; use infrared spectroscopy (FTIR) to characterize the structure of the product, figure 1 is the infrared spectrogram of the antiprotein unit; figure 2 It is the hydrogen nuclear magnetic resonance spectrum (HNMR) pictur...

Embodiment 2

[0034] 8.15g of dimethylaminoethyl methacrylate used in the step, 1.428g of mercaptopropylene glycol, 0.008g of azobisisobutyronitrile, 25 mL of tetrahydrofuran, and a reaction temperature of 65°C;

[0035] 1.3g flake graphite used in step (2), 1.0g potassium nitrate, 25 mL concentrated sulfuric acid, 5.5g potassium permanganate;

[0036] 1.8 g of diphenylmethane diisocyanate used in step (3), 0.13 g of 2,2-dimethylolpropionic acid, and 10 mL of acetone;

[0037] 0.2g of antiprotein unit used in step (4), 0.1g of hydroxylated graphene;

[0038] Others are the same as in Example 1.

Embodiment 3

[0040] 8.0 g of dimethylaminoethyl methacrylate used in step (1), 1.4 g of mercaptopropylene glycol, 0.008 g of azobisisobutyronitrile, and 25 mL of tetrahydrofuran;

[0041] 1.0g flake graphite used in step (2), 1.5g potassium nitrate, 25 mL concentrated sulfuric acid, 6.5g potassium permanganate;

[0042] 2.0 g of diphenylmethane diisocyanate used in step (3), 0.2 g of 2,2-dimethylolpropionic acid, 15 mL of acetone, 1.5 g of polyetheramine D2000, and 0.8 g of polyetheramine D230;

[0043] 0.2g of antiprotein unit used in step (4), 0.1g of hydroxylated graphene;

[0044] Others are the same as in Example 1. Example 4:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com