Preparation method of SF-Cd sustained release microspheres by microwave synthesis

A slow-release microsphere and sf-cd technology, which is applied in microsphere preparation, microcapsule preparation, food science, etc., can solve problems such as poor tensile strength and decreased thermal stability of silk fibroin, and achieve good foaming stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] The preparation method of embodiment 1 silk fibroin powder

[0060] The preparation method for making the silk fibroin powder of SF-Cd sustained-release microspheres, comprises the steps:

[0061] 1) Low temperature degumming

[0062] The traditional degumming method is more severe, requiring boiling at high temperature for several hours, and strong acid and strong alkali treatment. These methods will destroy the spatial structure of silk fibroin to a certain extent, resulting in the reduction of subsequent application performance and even the loss of its activity. . In this project, a milder low-temperature degassing treatment will be used to greatly retain the biological activity of silk fibroin.

[0063] After the impurities in the silkworm cocoon are removed and shredded, weigh a certain mass of silk fragments, and add deionized water and anhydrous sodium carbonate. The silk is completely submerged in the solution, stirred evenly, sealed and filled with nitrogen...

Embodiment 2

[0070] Embodiment 2 physical and chemical index analysis and characterization

[0071] (1) Determination of conventional ingredients

[0072] Determination of protein: Micro Kjeldahl method (GB5511-85)

[0073] Determination of fat: Soxhlet extraction method (GB5497-85)

[0074] Determination of moisture: 105 ℃ constant weight method (GB5512-85)

[0075] Determination of ash content: dry ashing method (GB5505-85)

[0076] (2) Determination of emulsification and emulsification stability

[0077] After being degraded by calcium chloride, silk fibroin will be endowed with good emulsification, foaming and stability. These good physical and chemical properties determine the application of silk fibroin in medical food and other fields [4] , so the research on the emulsification, foaming and stability of silk fibroin plays a decisive role in improving its application value.

[0078] A certain amount of silk fibroin is taken respectively to prepare silk fibroin solutions with a c...

Embodiment 3

[0235] Example 3 Structural characterization of SF-Cd and the influence of microwave on it

[0236] 1.1 Experimental materials

[0237] Table 4-1 Main experimental materials

[0238] Table 4-1 Main experiment materials

[0239]

[0240]

[0241] 2 Experimental methods

[0242] 2.1 Solubility of the product

[0243] Weigh a certain amount of product silk fibroin, add deionized water to dissolve, and prepare silk fibroin solutions with different pH values, stir at room temperature for 1 hour, centrifuge at 10000r / min for 10 minutes, take the supernatant, and use Coomassie brilliant blue method to determine the silk fibroin content in the solution.

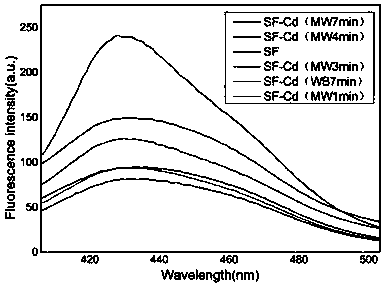

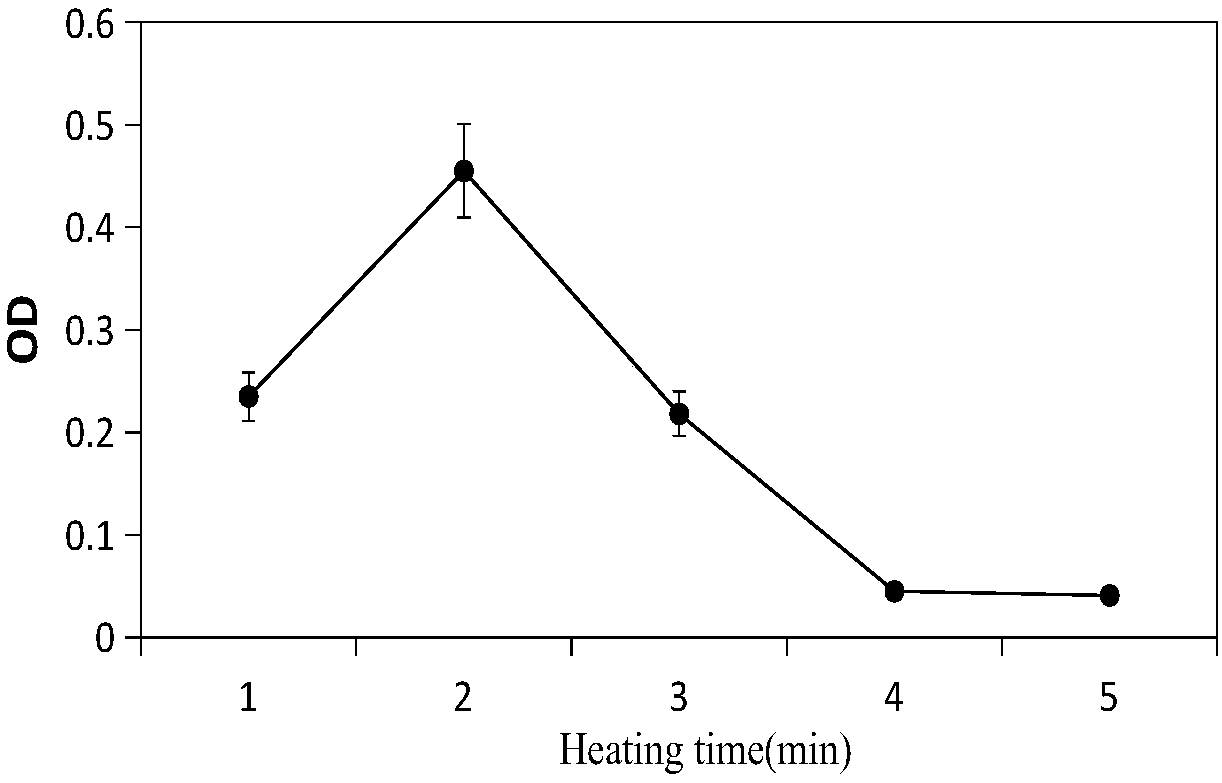

[0244] 2.2 Fluorescence spectrum analysis

[0245] The silk fibroin, β-Cd, and microwave reaction products were reacted under the same conditions for 1 min, 2 min, 3 min, 4 min, 5 min, 6 min, and 7 min respectively, among which silk fibroin and β-Cd were used as the control group. After the reaction was completed, a solut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Emission wavelength | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com